Feb 28, 2022

Understanding Electrical Cables

Electrical wiring is the basis of most electrical projects. For a successful renovation or remodeling job, you need to know how to identify electrical cables and determine the right kind of electrical wire for your application.

Learning the wiring basics is an essential first step for any electrical project. Although many people use the terms “wires” and “cables” interchangeably, they are slightly different. Wires are the individual conductors in a single jacket, while cables assemble two or more wires inside a jacket.

This guide will help you understand electrical wiring so you can identify wires when investigating issues and choose suitable materials for a new project.

Types of Electrical Wires

Knowing the types of electrical wire you might encounter can help you find the best wire for house wiring and other projects. Electrical wires are measured in gauges related to the wire’s diameter and current-carrying capacity. The higher the wire gauge, the smaller the wire. Most electrical wires are either copper or aluminum.

Other than size and material, electrical wires come in a couple of configurations:

- Stranded wire: Stranded electrical wire is a flexible woven strand of conductors, which you can easily pull through bends in the conduit — the tubing that protects the wire.

- Solid wire: The single, rigid conductor in solid wires is better suited for applications where you need to push them through the conduit.

Types of Electrical Cables

Individual wires can create various electrical cable combinations for many different applications when run together. Here are the four main types of electrical cables:

Romex® Nonmetallic Cables

The Romex® Nonmetallic (NM-B) cable is one of the most common brands of nonmetallic electrical cables found across indoor applications, primarily homes and small businesses. This cable typically has two or three conductors and a ground, all wrapped inside polyvinyl chloride (PVC) insulation and a jacket made of nylon. NM-B cables are available from two to 14 gauges and can withstand temperatures of 90℃, as long as the location is dry.

The most commonly used NM-B cables include the Romex® NM-B 14/3 cables, which are ideal for indoor outlets, three-way switches and split receptacle circuits. Electricians use Romex® NM-B 12/3 cables in three-way switches and split receptacle circuits.

Underground Feeder Cables

Underground feeder (UF-B) cables travel below ground to bring power to areas like detached garages, outbuildings and outdoor lighting and pumps. Its rugged construction and PVC jacket make it ideal for outdoor applications, direct burying and indoor applications where weather damage is a concern.

UF-B cables don’t need a conduit when buried, although they will need one in places where the cable exits the ground. UF-B cables can withstand temperatures of up to 90℃ and come in gauges from six to 14. These cables can have two or three conductors, which can be solid or stranded.

Metal-Clad Cables

As the name suggests, metal-clad (MC) cables have a metal sheath that makes them durable in unfinished and damage-prone areas. This cable is ideal in dry and wet conditions and in residential, commercial and industrial buildings. An interlocked aluminum jacket makes MC cables great for burial with a conduit, embedding in cement or plaster and more.

MC cables come in gauges from two to 14 with anywhere from two to four conductors wrapped in nylon jackets. These sturdy wires protect against demanding conditions and temperatures up to 90℃. Copper MC cables are made of bare, solid and stranded copper to meet a wide range of needs.

Tray Cable

Tray cable is one of the most versatile types of cable. Its construction consists of copper wire covered with a PVC jacket and thermoplastic, high-heat nylon (THHN) insulation.

Tray cable is available in gauges from two to eight and has three or four conductor options to help electricians and manufacturers complete many different projects. If you’re looking for a type of wire that does it all, tray cable is a great all-purpose cable.

SE-R Cable

Service entrance reinforcement (SE-R) cable is cable featuring copper wires surrounded by THHN insulation and a sturdy PVC jacket. It also has a ground wire. These materials give it UV and water resistance and flame retardance, making it good for both indoor and outdoor usage. When used outdoors, SE-R is not appropriate for direct burial, and electricians must use it in conduit.

Common uses for SE-R cable include use as an aboveground service entrance cable and for panel feeding to multi-residential buildings. It is rated for 600 volts and 90℃ in both wet and dry conditions. SE-R is available in different gauge sizes, from six to 4/0, to suit different applications. All options come in a gray jacket.

WesBell Electronics’ SE-R cable maintains many approvals from outside organizations, including the U.S. Military, ASTM International and UL Solutions:

- Military specification A-A59544

- ASTM

- UL 83

- UL 854

- Registration, Evaluation, Authorization and Restriction of Chemicals (REACH)

- Restriction of Hazardous Substances (RoHS)

When comparing S-ER vs. SE-U cables, service entrance unarmored (SE-U) cables have notable differences. The first is in their shape. SE-R cable is round, while SE-U cable is flat. The second is their ground wires, or lack thereof — SE-R has a ground cable, while SE-U does not. Because of this, electricians don’t commonly use SE-U for sub-feed applications like SE-R. However, they do use it in service entrances. Additionally, SE-U cables are not stranded, making them a little more time-consuming to use.

Types of Electrical Wires We Offer

As electrical applications vary significantly, you will need to source the right type of wire for your needs. Here’s an overview of the electrical wires we offer at WesBell Electronics and a brief explanation of their materials and uses.

Bare Copper

Bare copper wire is a vital element in various electrical cables, from overhead communication wiring to electronics, residential wiring and telecommunications. Uninsulated, solid wire is one of the best electrical conductors and comes in various configurations and gauges from two to 26. You can also find bare copper in individual wires and electrical cables.

Copper provides high flexibility and fair corrosion resistance, making it ideal for wiring in tight indoor spaces. In addition, grounding wires consist of bare copper. Manufacturers sometimes anneal bare copper wiring to strengthen it for extensive flexing and bending. However, bare copper wires must be used indoors or in conduit, as they cannot withstand very harsh conditions.

Tinned Copper

Bare copper has good corrosion resistance, although humid and hot conditions weaken this characteristic. In these applications, tinned copper is often the solution. You can even use it in projects near seawater, as it is also saline-resistant. Tinned copper wires are also uninsulated, but they have a tin coating. This coating prevents strands from fraying and offers the conducting benefits of copper wiring with some additional protection from deterioration.

Adding tin to a copper wire significantly improves its corrosion resistance in wet and humid environments while retaining its ability to conduct electricity. Tinned copper can withstand moisture and higher temperatures. Tinned copper wire is available in gauges two to 26, allowing electricians to use these wires in difficult-to-reach places and ground electrical systems.

TFFN

Electrical wire insulation comes in several materials to suit different applications. Some stranded copper electrical wires use thermoplastic flexible fixture nylon (TFFN), which consists of PVC insulation with a jacket made of nylon. TFFN wires have a bare copper conductor, but their insulation makes them suitable for outdoor, indoor and in-conduit applications.

The TFFN coating makes these wires resistant to water, heat, gas, moisture and oil. This makes TFFN wire suitable for a broader range of applications than bare copper wires. TFFN wire is resilient to temperatures in dry environments up ten to 90℃. TFFN wires are limited because they only come in 16- and 18-gauges.

THHN

THHN is another type of electrical wire insulation. These wires consist of a solid or stranded copper conductor, thermoplastic insulation like PVC and a nylon coating. The insulation provides excellent protection in high heat for the copper conductor within.

THHN wires are among the most common insulated wires because they meet most building codes. With excellent resistance to water, gas, chemicals, oils and heat of up to 90℃, these wires are ideal across various applications. THHN wire has a wide gauge range — sizes larger than one are measured in thousands of circular mils.

USE-2 Sola

Underground service entrance (USE-2) is a single-conductor electrical wire, which electricians commonly use underground. This wire provides wide-reaching power distribution capabilities with a temperature rating as high as 90°C and a voltage rating of 600 volts. These wires are ideal for several different applications, but the most common use is for photovoltaic power.

XHHW

Another copper wire type is cross-linked polyethylene, high-heat-resistant and water-resistant, or XHHW-2. This kind of insulation allows copper wire to serve in a wide range of general-purpose applications, granting it more durability and flexibility as well as several other beneficial characteristics.

How to Identify Electrical Cables

With so many different types of electrical cables, it can be challenging to cut through the confusion and ensure your wiring project is safe. These tips will help you identify electrical cables to determine what you’re looking at and what you need.

1. Decode the Colors

Manufacturers use color-coding on cables and individual wires to quickly tell electricians the cable’s or wire’s characteristics. Understanding a cable’s color helps you maintain consistent wiring and protect your project’s safety. The color of a cable’s outer sheath tells you information like the circuit’s amperage rating, which is the strength of its electrical current and the wire’s gauge.

However, using a color code for electrical cable sheaths is still optional and relatively new. If your project has electrical cables from before 2001, their colors may not comply with current color codes. This overview of standard electrical cable colors will give you the basic knowledge to determine a cable’s characteristics:

- Black: Cables with a black sheath have either six- or eight-gauge wire and deliver 40 to 60 amps. This includes cables like the Romex® NM-B 8/3.

- Orange: Orange-sheathed cables have 10-gauge wire and can handle 30-amp circuits. For instance, Romex® NM-B 10/3 cables have orange sheaths.

- Yellow: NM-B cables with a yellow sheath, like Romex® NM-B 12/2 cables, are rated for circuits with 20 amps. Yellow-sheathed cables are 12-gauge.

- White: White-sheathed NM-B cables, like Romex® NM-B 14/2 cables, are rated for 15 amps. Cables with white sheaths have 14-gauge wires.

- Gray: Gray cable sheaths are associated with UF-B cables, like the UF-B cable 14/2. This cable delivers 15 amps.

Individual wires within a cable are also color-coded. These colors signal the wire’s specified or preferred use:

- Red or black: These colors indicate that a wire is current-carrying or “hot.”

- White: White wires are usually neutral conductors, returning power to the service panel.

- Bare or green: Wires that are bare copper or green are grounded. You may also see grounded wires that are green with yellow stripes.

2. Know Your Labels

Labels on electrical cables consist of letters and numbers that help you determine a cable’s use at a glance. The information on your electrical wire markings includes the following:

- Numbers: One electrical cable classification combines two numbers with a hyphen between, like 12-3. The first number in this sequence denotes the conductor’s gauge, while the second refers to the number of conductors inside the cable.

- Letters: The labels on the outside of an electrical cable indicate the maximum voltage rating, the wire material and whether a ground wire is present. NM-B cables include labels like “G” or “w/G” for ground wires and “CU” for copper wires. UF-B cables may be labeled with their acronym plus “Sunlight Resistant.” Individual wires also have labels for their material — for example, THHN or TFFN.

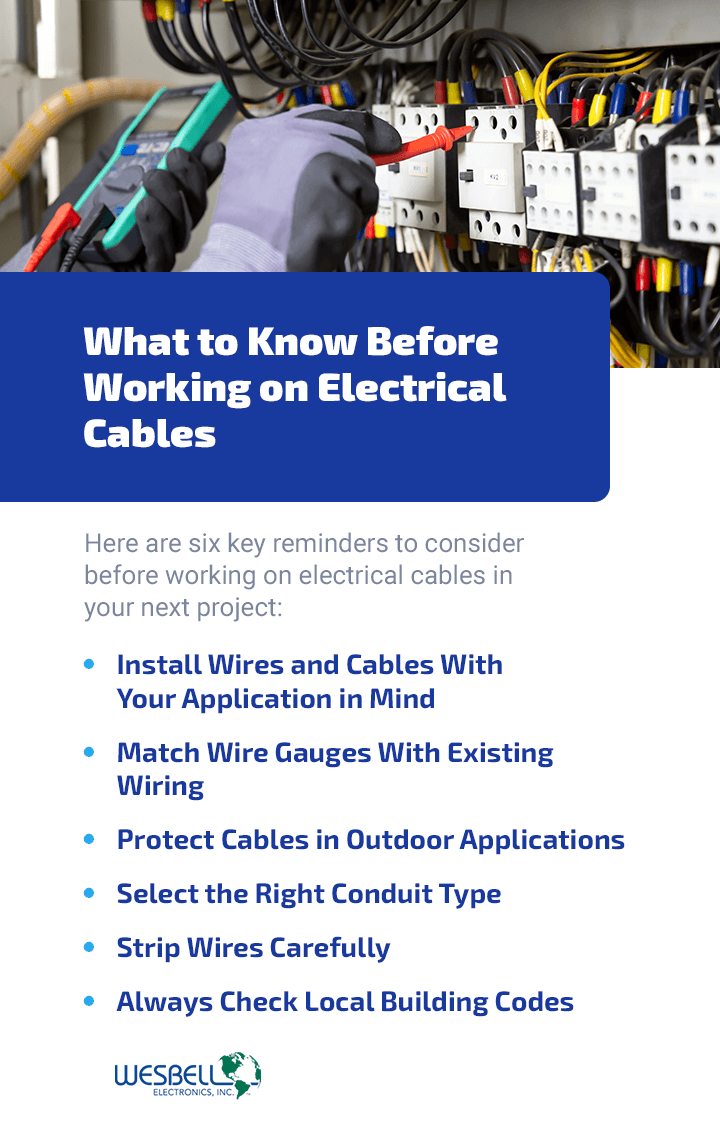

What to Know Before Working on Electrical Cables

Before beginning any electrical project, it’s crucial to learn how to understand electrical wiring and how to use it. Doing so ensures you complete your project successfully and safely. Here are six key reminders to consider before working with electrical cables in your next project:

1. Install Wires and Cables With Your Application in Mind

Your application determines the kind of electrical wiring you use. For example, Romex® NM-B cables are great for indoor use. However, they aren’t the most rugged wires you can find, making them unsafe for outside use. You will need to take additional precautions for outdoor projects or switch to a more durable cable, like MC cables.

Before picking wire for your project, ask yourself these questions to determine the suitable material:

- Is this project indoors or outdoors?

- Is there high moisture, heat or humidity present?

- Will the electrical wiring need to fit tight spaces?

- Would using a conduit protect this wire or cable from deterioration?

2. Match Wire Gauges With Existing Wiring

A wire’s gauge is specific to the amount of amperage the circuit uses. You’ll need to use electrical wire that can handle the current that is already flowing through the building. In residential projects, you’ll most commonly find 12- and 14-gauge wires. Larger gauges like six, eight and 10 are best with large appliances, electric water heaters and central air units.

If you’re adding an outlet or a switch, ensure you know the existing wire’s size before starting. It’s essential to use wire with the same gauge as existing wiring within a circuit, as this prevents short-circuiting and fires. Check the labels on the existing wire to determine its gauge.

3. Protect Cables in Outdoor Applications

Standard electrical cables have thinner insulation, making them better suited for indoor projects where walls and floors protect them. When installing wiring for an outdoor job, it’s vital to use a cable that can withstand corrosion, moisture, humidity and other damage.

Outdoor electrical cables use hearty insulation to protect the wiring. Direct-burial cables can be buried with or without a conduit and remain secure from deterioration. You can also use cables that are not rated for direct burial, although they require a conduit like a thick casing of PVC.

4. Select the Right Conduit Type

When you need to protect your electrical cables or wires, fitting them inside a conduit is an excellent option. Conduits offer all electrical cables and wires additional protection against moisture, corrosion and damage.

There are different conduit types to suit all applications. Metal conduits are not commonly used today, as flexible plastic conduits are more useful in tight areas. It’s also essential to select the correct size conduit. When running individual wires through a conduit, you must stay below the fill capacity, which depends on the wire gauge, conduit size and material.

5. Strip Wires Carefully

Stripping electrical wire is the process of removing the PVC coating without nicking or damaging the conductors underneath. Wire stripping is one step in creating connections in all kinds of electrical projects. If done incorrectly, the connection could be interrupted or a short circuit could occur.

For the fastest and most accurate wire stripping, use a wire stripping tool. These wire strippers are for specific types of wire, so be sure to use the right kind.

6. Always Check Local Building Codes

It’s essential to check local building codes before starting any electrical project, as you may need to obtain special permits. The National Electrical Code (NEC) regulates the types of electrical cables and wires used in specific applications. These regulations often vary between states. Check with your local code enforcement department so you have the guidance you need.

It’s also a good idea to have your local building code inspector examine your installation once it’s complete to ensure you’ve followed safety regulations.

Choose WesBell Electronics for Your Electrical Cable and Wire Needs

At WesBell Electronics, we sell high-quality electrical wires and cables to suit various projects across residential, commercial and industrial applications. Our cost-effective and long-lasting materials will help you get the best results from your electrical project.

Our expert technicians can help you determine the correct wire or cable for your job. We also offer wire processing services to take care of the wire cutting, stripping and preparation for you. Get in touch with us today to learn more about our services.