Dec 29, 2021

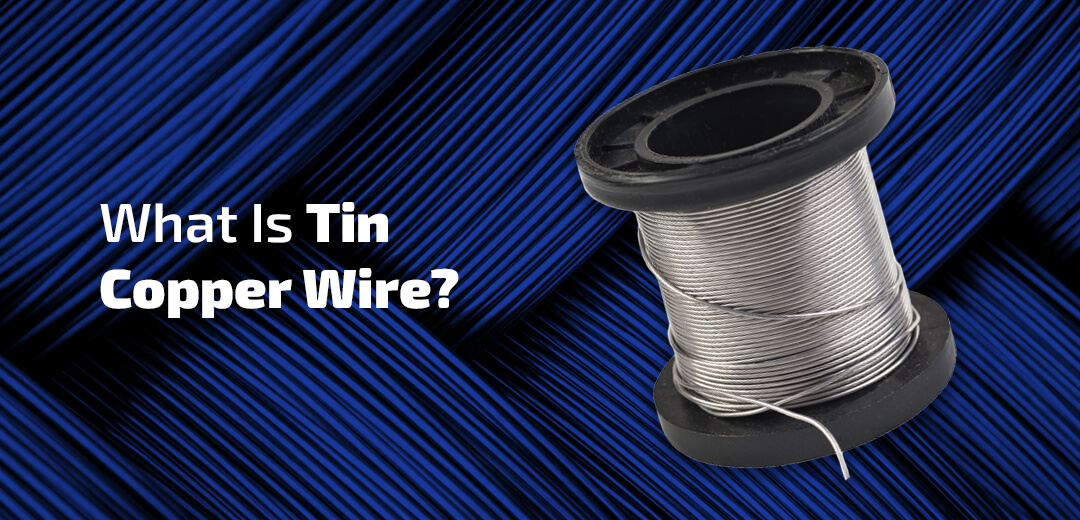

What Is Tin Copper Wire?

Tin copper wire is an alternative to using bare copper wire in electrical connections. One critical difference between tinned wire and bare wire makes tinned copper wire more suitable for specific applications. If you’re unsure which type of wire would be better for your situation, this guide can help you determine the benefits of tinned copper wiring, why it’s more suitable and when it’s best to use tinned wire instead of bare wire.

What Is Tinned Copper Wire?

Tinned copper wire is copper wire coated with tin. Copper is a desirable material because it is highly conductive. However, copper is also highly susceptible to oxidation or erosion. Tin has properties that make it more durable than copper. Coating bare copper wire in tin gives the wire the conductive properties of copper while using the tin to prevent oxidation and protect the copper.

Tinned copper wire is a dull silver color and is pliable and versatile, making it ideal for corrosive environments that reach high temperatures or receive a lot of moisture. Applications, where humidity, acidity, oxygen and water can reach the wire, are ideal situations in which to use tinned copper wire.

Tin vs. Bare Wiring

Tinned and bare copper wiring are effective, depending on their environment. The most significant difference between tinned wire and bare wire is the resistance to oxidation and erosion. The metal surface of bare copper wiring chemically reacts with elements like oxygen and water, causing the metal to corrode and tarnish. When this occurs, copper turns from bronze to pale green — think of the Statue of Liberty. This process can happen quickly, and once it starts, it’s hard to stop, especially on wires.

Tin coating can significantly reduce the oxidation process. A protective tin layer can add years to a copper wire’s life, especially in high-heat applications. When a copper wire’s operating temperature gets too high, it can’t resist erosion as effectively. Tin coating can withstand high heat, making it the better option when heat is involved.

Is Tinned Wire a Better Conductor?

Copper is an excellent conductor, and the bare wire has its place in specific applications. When properly taken care of and in ideal conditions, bare copper wire can be a more efficient and affordable option than tinned copper wire. However, just as there is a perfect place for bare copper wiring, tinned wiring also has its time and place.

When You Should Use Tinned Copper Wiring

Tinned solid copper wire can suit a wide range of purposes because they are non-corrosive and have an impressive ability to conduct electricity. The ideal location for tinned copper is one in which there is constant exposure to dampness or moisture. Tinned copper wire is used primarily in places that are hard to reach.

Both bare and tinned copper wires are common in ground electrical systems. Grounding wires shouldn’t transmit electrical current because they can electrocute anyone who might touch the wire and the incident could be fatal.

Copper wire is available in a variety of sizes and tempers. It is an all-purpose wire, but when electricity transmission is involved, it is better not to use this material because it can electrocute no matter how low the voltage may be.

Tin coating doesn’t need to substitute for copper wiring in every situation, though there are some scenarios where tinned wiring is more suitable.

- Constant exposure to moisture: Moisture can be one of the most damaging things to copper wire because it causes corrosion. In any application that may leave the wiring exposed to water, use tinned wiring. For example, any copper wiring in a water treatment plant should have tin coating to limit its exposure to the surrounding moisture.

- Electrical grounding systems: Electrical grounding systems give excess electricity a safe route back to the ground. Tinned copper wire is ideal in this application because of the potential for high temperatures. It’s also possible to use bare copper wire for electrical grounding, though it may be somewhat less safe.

- Outdoor or underground uses: In places like subway systems or where copper wiring is necessary outdoors, tinned wiring can be particularly useful. Using bare copper in these situations would expose it to weather and elements that would cause the wire to erode. Tinned wire can withstand the elements, requiring fewer replacements.

- Exposure to saltwater: Saltwater is highly corrosive, so tinned copper wire is better in situations near the ocean. The saltwater, ocean spray and moisture will quickly get to the copper. If crucial wiring eroded while out at sea, a ship’s features could malfunction. It’s best to use tinned wire on boats or other marine applications to ensure the wiring lasts as long as possible.

Anytime the wiring might encounter corrosive elements, use tinned copper wiring. Despite the extra cost, tin coating will protect the copper wiring from damage, which can be time-consuming and costly to repair otherwise. If you’re ever unsure of which option to use, its environment will be a determining factor.

Why Use Tinned Copper Wire?

The advantages of tinned copper wire are numerous. Despite the additional expense associated with tinned copper wire, the investment will pay for itself in the right situation.

Consider the following benefits of tinned copper wires.

- Works the same as bare copper wire: Tinned copper wire has the same conductivity as bare copper wire, but with extra protective coating. This characteristic allows people to use copper wire in less-than-ideal situations.

- Prevents corrosion: One of the most significant benefits of tinning copper wire is protecting the copper against rust. Many elements can degrade copper, including the oxygen in the air. Applying a tin coating to bare copper wire can help prevent erosion because tin can withstand the elements for longer.

- Extends wire life: Tin’s protective properties help extend the life of copper wiring. With a protective tin coating, copper wires can last significantly longer without signs of corrosive damage. Investing more in the right wire for the job can make the difference between frequent replacements and a long-lasting product.

- Easy to solder: Soldering is a technique used to connect wiring. Tin is a common material used in soldering, which makes tinned copper wiring easy to solder.

Tips for Buying Tinned Copper Wire

Tinned copper wire can be purchased in stranded or solid type, and you can choose between hard or soft wire. You can also purchase it by meter or spool. Spools can be a better choice if you need lots of wire because you will be able to save by ordering in bulk.

There are many sellers that offer tinned copper wire, and you can compare tinned copper wire prices immediately when you browse online. If you are after a large amount of wire, look for the seller that has the best offer, such as free shipping with large purchases. You should also look into the reputation of the seller to make sure that the wire you are purchasing is within the given standards for safety.

The National Electrical Code (NEC) has specified many important standards to abide by. These rules were created to ensure constant safety and protection for manufacturers and users. Stay away from sellers that have a reputation for selling unsuitable wires, even if offered at very low prices — you’ll end up paying a higher price when accidents are caused by faulty products.

Be sure to think carefully about where you buy your tinned copper wire. It is important that you are buying quality materials that pass all necessary requirements. Just because you’re using an all-purpose wire does not mean that you won’t have safety standards to follow. It is always better to be cautious, so make sure you are working with reputable merchants who have a track record of success.

Is Tinned Copper Wire Safe?

Like any electrical wire, tinned copper is unsafe if damaged or improperly installed. However, it provides many safety advantages over bare copper wire, especially in corrosive environments. The tin plating provides protection from humidity, high temperatures, weather and water while still retaining the conductive properties of copper, providing longevity to a material that could otherwise corrode quite quickly and cause safety concerns.

Historically, you could run into trouble with older rubber insulation with low heat resistance, but modern manufacturing practices have taken care of this problem.

Is Tinned Wire Better Than Bare Wire?

Considering the safety characteristics outlined above, you can see where tinned copper offers better longevity. It can withstand poor weather and corrosive elements, making it better than bare wire in many marine and underwater applications. Part of this solid performance comes from copper’s resistance to galvanic corrosion. Galvanic corrosion occurs when a metal is in contact with another metal and creates a point of electrical contact, deteriorating one of the pieces.

Tinned copper wire can also provide better electrical conductivity than other types of copper wires. Copper is already an excellent choice for high-powered applications due to its high electrical and thermal conductivity, malleability, strength and machinability, but tinned copper adds capabilities for specialty applications and resistance to the elements. It allows copper to serve as a more practical and wide-reaching cable that stands up to many different situations. That’s part of why it’s used so frequently today.

The biggest advantage of tinned wire is its corrosion resistance. It can last up to 10 times longer than non-tinned copper, and it isn’t difficult to manufacture. There is a drawback, however, and that’s its higher cost. Tinned copper wire prices can be as much as 30% higher than bare wire. You won’t want to use it in environments where it isn’t necessary — if corrosive properties like acidic agents, heat or humidity aren’t an issue, you can often use non-tinned wire instead.

Shop Copper Wire and More at WesBell Electronics

If you’re searching for tinned copper wire or bare copper wire, look to WesBell Electronics. We started as a wire and cable distributor and have expanded to a wiring and cable service provider and distributor. We offer various wires and cables to meet your project’s needs. We’re even proud to offer custom services and products. With over three decades in business, our experienced team is here to help you find the products you need.

Browse our selection of products and get in touch with us if you have any questions or requests.