Feb 8, 2024

Shielded vs. Unshielded Cables

Choosing between shielded and unshielded wire involves comparing several factors, particularly the level of surrounding interference. You must assess the fundamental differences, their best-suited applications (such as fire cable), budgetary allowances, cable flexibility and its ability to shield against electromagnetic interference.

Shielded cables are typically more expensive, bulkier, less flexible and intended for harsher environments with high EMI potential. On the other hand, unshielded cables are cheaper and easier to install, are only safe to use in dry indoor areas and provide minimal EMI protection. Use this guide to help you make an informed decision when selecting cabling for your application.

What Is Electromagnetic Interference?

EMI is an electronic disturbance generated by other electronic devices or electrical sources. It usually comes from devices like power cables and high-speed cabling. EMI “noise” is all around us, and depending on the intensity, it can either be irrelevant or enough to cause electronic devices and systems to experience the following:

- Speed and performance drops

- Error rate increase

- Data loss

- Signal degradation

- Cross talk

What Is Shielded Multiconductor Cable?

Different variations of shielded multiconductor cable feature a protective layer wrapped around the inner insulated conductors. In a shielded multiconductor cable, the inner wires, often made of copper, are surrounded by a layer of material, such as braided copper strands, aluminum foil or some type of polymer. This shielding layer keeps EMI out and retains the integrity of the signal moving through the cable. Foil or tape shields are the most effective option since they completely coat the cable, blocking EMI. Braided shielding is more durable but less effective in preventing EMI.

Whichever form it takes, shielding is an important part of making sure these cables perform as needed in demanding applications. EMI can cause signal degradation, cross-talk, reduced speeds and other performance issues, and critical operations must minimize these as much as possible. You’ll find shielded cables in tasks like high-speed data transmission, computer connections, control circuits and industrial equipment. They can also replace multiple hook-up wires in some situations.

Shielded multiconductor cable from WesBell Electronics uses gray polyvinyl chloride (PVC) jacketing and UL1061-approved insulation. The inner wires are made of tinned copper strands, color-coded for ease of installation and coated in an aluminum polyester foil shield. The number of conductors ranges from two to six, depending on the size of the wire, which can vary between 14 and 24 American Wire Gauge (AWG). Overall, the wires support up to 300 volts and 80°C.

Types of Shielded Cables

There are three types of shielded cables.

- Foil-shielded cables: These use a thin layer of either copper or aluminum for protection, offer reasonable flexibility and are suitable for various applications. Foil or tape shields are often the most effective option, since they surround the cable, blocking EMI.

- Braided shielded cables: These have a wire mesh surrounding the internal wiring and offer robust protection against mechanical stress. Braided shielding is more durable but less effective in preventing EMI.

- Combination shielded cables: These are ideal for applications where you need the durability of braided shielded cables and could benefit from the combined protection against high levels of EMI. However, they are heavier, bulkier and less flexible than any other form of multiconductor cable.

What Is Unshielded Cable?

Unshielded multiconductor cable options still offer some protection against EMI and its unwanted effects. As the name implies, unshielded cable differs from many other types of multiconductor cable by its lack of shielding. Cables that do have shielding use it to ward off electromagnetic interference (EMI), which can cause crosstalk between the circuits, degrade the data passing through the cable, increase errors and slow the transmission rates. Unshielded cable doesn’t forego this protection altogether. Rather, it just finds it differently.

They do not include a foil or braided shield — instead, unshielded cable twists its wires into pairs, which accomplishes the goal similarly, though not as effectively as most shielded cables. Shielded cables are often used in high-speed data applications, such as data center networks, but unshielded cable is often a more affordable and flexible approach for less-demanding environments like your typical office space.

Other benefits of unshielded wire include its flexibility. Since there’s no shield in place, the wire is much thinner and can bend more easily. If there is no EMI present, unshielded cable can even run faster than shielded cable in EMI-free environments. EMI typically comes from electrical devices, including power cables and high-speed cabling.

Comparing Shielded and Unshielded Cable

Shielded and unshielded cables address EMI differently. Also, each of them has intended use cases. Though you might assume using shielded cables with foil and braid makes sense for all applications, there are drawbacks to using this type of wire in some cases. Understanding the advantages, disadvantages and possible applications of each will help you make an informed decision.

Shielded Cable Pros and Cons

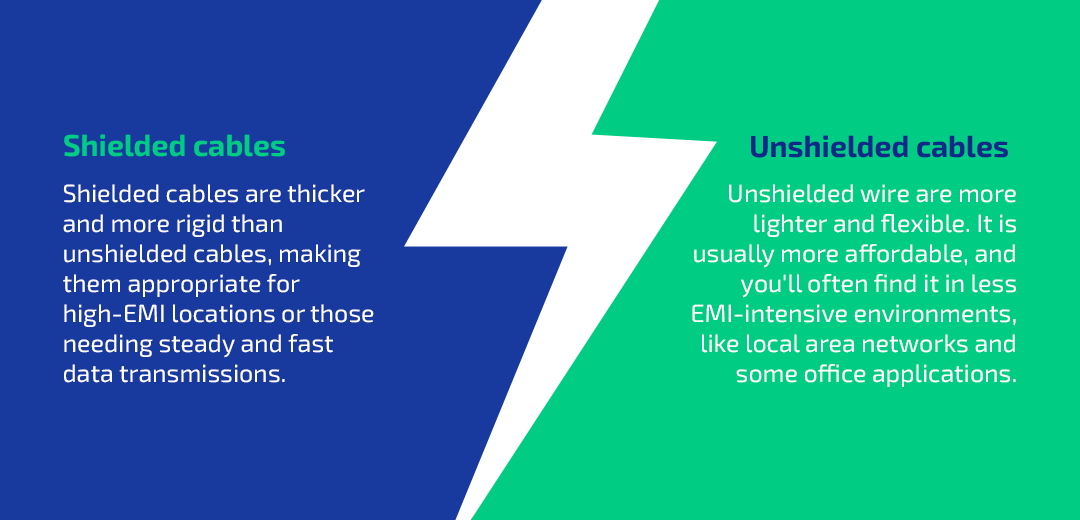

Shielded cables are thicker and more rigid than unshielded cables, making them appropriate for high-EMI locations or those needing steady and fast data transmissions.

Here are the pluses of shielded multiconductor cable:

- Effective at mitigating EMI and maintaining signal integrity

- Suitable for high-traffic networks

- More durable than unshielded

- Resistant to moisture and abrasion

- Fewer chances of technical issues

- Can replace multiple hook-up wires in some situations

Consider these potential downsides of shielded multiconductor cable:

- More expensive

- Less flexible

- Bigger and heavier

Unshielded Cable Pros and Cons

Instead of adding a material layer, unshielded cables twist the wires to reduce EMI. This technique makes the cables lighter and more flexible but less effective at keeping the signal steady. Unshielded wire is usually more affordable, and you’ll often find it in less EMI-intensive environments, like local area networks and some office applications. Unshielded wire also typically can’t support higher voltages.

Before choosing an unshielded multiconductor cable, you should understand these benefits:

- Much thinner and more flexible due to the lack of shield

- Can run faster than shielded cable in EMI-free environments

- Cheaper option than shielded, particularly for large-scale use

- Installation is usually quicker and easier

- Often takes up less space than shielded

Unshielded multiconductor cable also has some minuses:

- Increased risk of EMI, which can cause problems

- Not ideal for high-traffic networks with increased EMI risk

- More prone to scrapes, abrasion and damage — including moisture

Shielded Cable Applications

Multiconductor cables are used in many environments, some of which have high EMI. EMI can cause several undesirable effects, and adding shielding can help a cable better withstand it. This quality makes it a popular choice in many demanding data environments.

The following applications use shielded cables, typically where there is a high chance of EMI:

- High-speed data transmission

- Computer connections

- Control circuits

- Industrial equipment

- Industrial automation systems

- Telecommunications infrastructure

- Medical equipment

- Recording studios

Unshielded Cable Applications

Unshielded cable is a popular solution to many indoor networking systems, thanks to its cost-effective approach to limiting signal interference. Like its shielded counterpart, unshielded cables come in several configurations that vary in size and conductors.

With its particular characteristics, unshielded cable is an excellent choice for Ethernet wires and local area networks. You’ll also see it replacing PVC hookup wires and in several essential applications, such as:

- Burglar alarms

- Intercom systems

- Internal phone networks

- Public address systems

- Cash registers

- Remote control circuits

Consider Olflex for High-Performance Applications

Olflex is a renowned brand of electrical wiring that offers high-quality cables intended for several industry needs. These cables have a reputation for performance and reliability, and this trusted brand offers a range of shielded and unshielded wires.

Olflex Cable Shielded 190CY and Unshielded 190

Wiring and cables are essential for computers and electronics. One notable brand of multiconductor electronic cables on the market is Olflex wiring from Lapp Group, and under their product line are theOlflex Cable 190 Unshielded and Olflex Cable 190CY Shielded series.

Technical Specifications — 190 and 190CY Series

The Olflex 190 and 190CY series feature multi-conducting compact power cables that resist water-based, artificial and mineral oils. These PVC cables were considered oil-resistant after passing several federal oil tests like the UL AWM 21098 test, and the oil res 1 and the oil res 2 tests, the CSA-AWM 1 and 2 tests, the CSA C22.2 test, the Section 8.8.8 and Section 7.6.12.1 oil resistance tests, and the Norma Official Mexicana test. Aside from oil resistance, the cables also passed the UL 1277 crush and impact test. Hence, they work in most arid, cool or wet environments.

For technical specs, the Oflex® 190 series could be purchased with a minimum bending radius of at least four times in cable diameter for installation and up to at least six times in cable diameter if with a shield. The products could also withstand a temperature ranging from -50 to 90 degrees Celsius for flexible purposes and at least -400 up to 900 degrees Celsius for stationary purposes. The optimal voltage range that these wires can handle is up to 600 Volts, but a test range of up to 3000 Volts is also achievable. The stranding of the inside conductor is considered Class 5 VDE 0295 of fine wire, color-coded as black with white numerals and with a yellow or green ground color. In terms of construction, the standard Oflex 190 power cable comes with copper conductors that are thinly stranded, filled with non-absorbing stuffing and coated with a dry lubricant. All-in-all, the conducting materials are covered with an oil-resistant PVC material.

The Olflex 190CY withstands signal distortion and impulse interference while negating EMI. It shares the same build and construction with the standard Olflex 190, which includes thinly stranded copper material, a gray PVC wire insulator, a non-absorbing stuffing and a dry lubricant. Additionally, it has an 85% coverage copper braid to protect the conductors from interference.

Olflex 190 can handle up to 600 volts and 194 degrees Fahrenheit and has UL, CSA, CE and RoHS approvals to fit most manufacturers’ requirements. The 190 series has all-black numbered conductors with a green/yellow ground wire. The shielded version has a braid overall shield to block electrical interference.

Olflex Cable Shielded 190CY Applications

You might choose the Olflex 190 and 190CY series if you want power cables with a compact design, oil-resistant properties, low electrical interference and adequate conducting capacity. It applies to various uses, from simple household appliances to complex ones such as desktop computers, laptops and most data processing.

Olflex Cable Shielded 890CY and Unshielded 890

Many wires and options are available for computers and electronics today, and one notable example on the market today is the Olflex cable 890 unshielded and Olflex cable 890CY shielded series.

Technical Specifications — 890CY Series

Olflex 890 can accommodate up to 600 volts and 194 degrees Fahrenheit. It has UL, CSA, CE and RoHS approvals to fit most manufacturers’ needs. The 890 series has all-red numbered conductors with a green/yellow ground wire.

The standard Olflex 890 unshielded type is the usual choice of most technicians and electricians for its reliable performance and convenient usage. It is available in four different types: the Olflex® 890 20 AWG, the Olflex® 890 16 AWG, the Olflex® 890 18 AWG, and the Olflex® 890 14-2 AWG. The primary difference between the types of power cords is the gauge of AWG, which defines their circumference. Aside from that, every wire comes with three to 34 wire conductors and PVC insulation that provides oil resistance.

The shielded type or the CY series is the next type of wiring. The main characteristic of the shielded type, which includes the Olflex® 890 CY AWG 20 Shielded, the Olflex® 890 CY AWG 18 Shielded, the Olflex® 890 CY AWG 16 Shielded, and the Olflex® 890 CY AWG 14-2 Shielded, is the thick copper braid wrapped around the main conducting surface. This new addition is designed to suppress electronic interferences to promote smooth electric conductance. Besides the copper braid, the CY series has two other insulation jackets to maintain proper conductance: the black PVC coat, and the oil-resistant PVC coat. All the oil-resistant jackets are approved by federal oil tests like oil res 1, oil res 2, CSA, and UL.

The leading characteristic of the shielded type is the thick copper braid wrapped around the main conducting surface. This new addition suppresses electronic interference to promote smooth operation.

Besides the copper braid, the CY series has two other insulation jackets to maintain proper conductance — the black PVC coat and the oil-resistant PVC coat. All the oil-resistant jackets have passed federal oil tests like oil res 1, oil res 2, CSA and UL.

Olflex Cable Unshielded 890 Applications

Professional electricians prefer the Olflex 890 and 890CY series because of its applicability in most situations and machinery. The Olflex 890 and 890CY series is a good choice for electronic purposes with low interference and oil resistance. Its manufacturers recommend these options for use in:

- Scaffold robotics

- Cable pathways

- Machine-powered tools

- Drop-anywhere units

- Conveyor belts and systems

- Flexing applications

- Other automatic tools

Aside from the shielded and unshielded variants, each comes in different bundles of conductors, depending on the situation.

Choose WesBell Electronics for Your Multiconductor Cable Needs

At WesBell Electronics, we’ve met our customers’ unique needs since 1988. Our experienced staff enjoys helping customers find the best cable for any job. If you are unsure which cabling is appropriate for your project, we’re happy to walk you through it.

We supply various multiconductor electronic cables, including shielded and unshielded options. We also offer comprehensive wire processing services to save you time with quality results. After exploring our shielded and unshielded multiconductor cable options, reach out to us to learn more about the products or inquire about our other offerings.