Multi Conductor Electronic Cable Assembly Preparation

Order FPLP, FPLR, Unshielded, Shielded, Fire Alarm Cable, PVC, Speaker and Thermostat Wire Online

Companies upgrade to multiconductor electronic cables when they are using multiple wires for a single application or when added protection is needed for the copper strands. Insulation covers copper for a specific reason which is to protect the copper from impact, corrosion, heat, voltage and connection failures. Rarely, an overall jacket can be used to simply combine all of the individual wires into a cable because it’s easier to install and it looks neater, however, the jacket is still used for some form of protection one way or another. WesBell can service the cable before we ship it. Our services for cable include cutting it to length, coiling it, removing the outer jacket a few inches and stripping the insulation from each conductor.

Contact Us for Multi-Conductor Electronic Cable Assembly Preparation

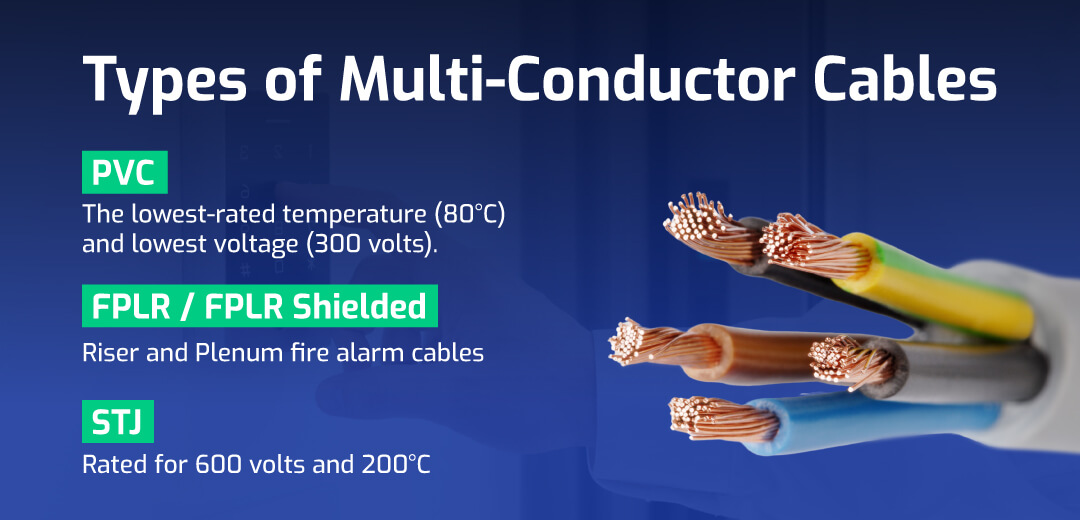

Types of Multi-Conductor Cables

Since wire and cable insulation is designed to protect the copper strands the most common types of multiconductor cables are related to temperature, voltage and environmental impact. The most basic version is called PVC / PVC, which is the lowest-rated temperature (80°C) and lowest voltage (300 volts). Similar cables with different characteristics are FPLR, FPLR Shielded, FPLP and FPLP Shielded, which are Riser and Plenum fire alarm cables. These cables come in two versions: shielded or unshielded.

Any application with a need for higher temperature or voltage will require a more expensive cable with higher ratings. For example, STJ (Shielded Tape Jacket) cables are rated for 600 volts and 200°C for applications that typically exposed high amounts of heat near the wires. Perhaps there’s a wire harness running to a control panel in a furnace near the pilot flame, and if it’s close enough it may require an STJ cable.

However, standard electronic devices do not require out-of-the-ordinary approvals because most electronics are used indoors and away from heat. The voltage level is also much lower than 300 but the standard 300-volt cable will suit the application just fine. On the other hand, stoves have control panels with wire harnesses running through them so the heat can most definitely increase above the standard level and require something more expensive.

Shielded Multi-Conductor Cables

There are a few types of shields to consider when your application needs to block EMI (Electromagnetic Interference). The lowest-priced and most basic type of shield is an aluminum foil polyester shield that looks and acts very similar to aluminum foil. The magnetic field that surrounds copper as it conducts electricity will minimize with a shield around the conductors. The shield could be an overall shield which means it covers all of the conductors in the cable and sits just inside the cable jacket. There are also individually shielded cables that wrap a shield around two conductors multiple times. If there is 5 pairs of wires twisted together, each pair might have a shield within the same cable.

Another type of shield is a braided shield which uses thin copper strands to form a circular weave that looks similar to a Chinese finger trap toy. This braided shield wraps around all of the conductors and sits just inside the cable jacket. It’s a bit rarer to find an individually shielded cable using braid shields, but it does in fact exist at a decent price point. A final type of shield for these cables would be a combination of the two, a foil braided shield, which incorporates both shields in the same cable. STJ cables require the braided shield because the manufacturing process is completed at a very high-temperature level which would melt the foil shield into the jacket.

Electronic Cable Manufacturers

There are numerous electronic cable manufacturers for PVC cables, but far fewer for STJ cables. One of the easiest types of copper cables to manufacture (wire or cable) is that with PVC insulation because it’s basically the starting point of “normal” without any bells and whistles. The most basic indoor wire that is meant to connect electricity will have no need to resist gas, oil or outdoor environmental conditions. When applications require insulation to resist gas, oil and outdoor environmental conditions the wire and cable engineers will need to design a material that will resist those elements for many years. We don’t have to worry about a custom cable in this situation because higher voltages and temperatures are quite common and so are the cables to support the demand.

Industry favorites for designing, engineering and manufacturing PVC multiconductor electronic cables are General Cable, Quabbin Wire, Alpha Wire and Belden. Just like in most industries, there is brand name recognition for wire and cable companies. Alpha and Belden both have strong brand recognition and hold huge market shares in much more than just PVC electronic cables. They each have multiple proprietary trademark cables that only they can sell, but, of course, at a slightly inflated price. However, if you want more reasonably priced cables that hold approvals with UL, CSA, etc., you can go with General Cable or Quabbin Wire for your needs. General Cable’s brand “CAROL” cables are competitively priced.

Multiconductor Electronic Cable Coiling Services

If you want to order multiconductor electronic cable and services now, contact our team online or call us today!