Pre Cut Wire and Stripped Hook Up Wire

Order Pre Cut Wire, Stripped Wire, Striped Wire and Tin Dipped Wire Online

Table of Contents

- Hook Up Wire Cut to Length and Wire Stripping Services

- Hook Up Wire Service Options

- Advantages of WesBell Wire Cutting and Stripping Services

- Industries That Benefit from WesBell’s Cutting and Stripping Services

- Answers to Frequently Asked Questions about Pre Cut Wire and Wire Stripping Services

Contact Us for Pre-Cut Wire and Stripped Hook-Up Wire

Hook Up Wire Cut to Length and Wire Stripping Services

WesBell Electronics offers several types of quality hook up wire, also called hookup wire, as well as quality preparation services for pre cut wire including wire cut to length and stripping, striping, twisting, and tin dipping. For more than 30 years, our team’s outstanding service and consistent quality has earned the loyalty of clients across multiple industries throughout the U.S. and Canada. We are proud to be the first wire manufacturer to offer cutting, stripping, striping and tin dipping online, and even more proud that our hookup wire and electronic cable are helping to safely and effectively power thousands of electrical and electronic products produced by small to mid-size companies for use by people all over the world.

Choose from Several Pre Cut Hook Up Wire Types, Colors, and Services

You can choose from hook up wire insulated with either PVC or high-temperature insulation to achieve the voltage and temperature capacity you desire for your wiring. Select from 10 standard wire colors, as well as 10 wire striping colors, should you choose the additional service of striping.

When you order 250 feet or more of a colored wire, you may add these optional services

- Spiral striping added to your hook up wire

- Twisting together of two hook up wires

- Cutting the stranded wire to a specified length and stripping the ends of the insulation from each side

Each service is performed to order based your needs and specifications, thereby adding to the overall price. Once you place an order, our team promptly enters it into our internal project tracking system and we begin to process your order, as outlined below. This streamlined ordering process makes it easy for you to manage and maintain records of your orders for wire products and services.

8 Types of Hook Up Wire Available Online

- Description: WesBell Kynar wire wrap has a solid silver-plated copper conductor with PVC

insulation. Kynar has a very thin insulation thickness of .004 inches and a

temperature rating of 105°C. - Construction: Solid silver-plated copper; Kynar PVC insulated

- Approvals: RoHS Compliant; UL1423 approved

- Applications: Wiring of business machines and computers not subject to damage

- Description: WesBell Type E wire is also known as M16878/4 wire and PTFE wire. It’s rated for 600 volts and higher than normal temperature of 200°C. Type E wire is commonly used in electrical and electronic applications where high temperature is encountered.

- Construction: Silver plated copper strands; PTFE insulated

- Approvals: RoHS Compliant; UL1213; CSA; M16878/4; 600 volts; 200°C

- Applications: Internal wiring of appliances; Device manufacturing; Electronics where high temperature is encountered

- Description: WesBell Type EE wire is also known as M16878/5 wire and PTFE wire. It’s rated for 1000 volts and higher than normal temperature of 200°C.

- Construction: Silver plated copper strands; PTFE insulated

- Approvals: RoHS Compliant; UL1180; CSA; M16878/5; 1000 volts; 200°C

- Applications: Internal wiring of appliances; Device manufacturing; Electronics where high temperature is encountered

- Description: WesBell Type ET wire is also known as M16878/6 wire and PTFE wire. It’s rated for 250 volts and higher than normal temperature of 200°C.

- Construction: Silver plated copper strands; PTFE insulated

- Approvals: RoHS Compliant; UL1371; CSA; M16878/6; 250 volts; 200°C

- Applications: Internal wiring of appliances; Device manufacturing; Electronics where high temperature is encountered

- Description: WesBell UL1007 Wire has stranded tinned copper strands and a 300 volt PVC insulation. UL1007 is also approved to CSA standards and UL1569 for 105°C. It passes a UL VW-1 flame test and is most commonly used as wire for appliances.

- Construction: Tinned copper; PVC; .016 Insulation Thickness

- Approvals: RoHS Compliant; UL1007; UL1569; CSA; VW-1 Flame; 105°C; 300 Volts

- Applications: Internal wiring of appliances; Device manufacturing; Electronics

- Description: WesBell UL1015 Wire has stranded tinned copper strands and a 600 volt PVC insulation. UL1015 is also approved to CSA standards and UL1230 for 105°C. It passes a UL VW-1 flame test and is most commonly used as wire for appliances.

- Construction: Tinned copper; PVC; .030 Insulation Thickness

- Approvals: RoHS Compliant; UL1015; UL1230; CSA; 105°C; 600 Volts

- Applications: Internal wiring of appliances; Device manufacturing; Electronics

- Description: WesBell UL1028 Wire has stranded tinned copper strands and a 600 volt PVC insulation. UL1028 is also approved to CSA standards and for 105°C. It passes a UL VW-1 flame test and is most commonly used as wire for appliances.

- Construction: Tinned copper; PVC; .030 Insulation Thickness

- Approvals: RoHS Compliant; UL1028; CSA; 105°C; 600 Volts

- Applications: Internal wiring of appliances; Device manufacturing; Electronics

- Description: WesBell UL1284 Wire has stranded tinned copper strands and a 600 volt PVC insulation. UL1284 is also approved to CSA standards and for 105°C. It passes a UL VW-1 flame test and is most commonly used as wire for appliances.

- Construction: Tinned copper; PVC; .030 Insulation Thickness

- Approvals: RoHS Compliant; UL1284; CSA; 105°C; 600 Volts

- Applications: Internal wiring of appliances; Device manufacturing; Electronic

Project Preparation and Testing Delivers Quality Results:

The WesBell Electronics team follows this strict process to prepare each order for production:

- We set the machine to cut the wire to 6 inches, with a semi-strip on both ends of 0.25 inches

- We test the first 10 pieces for pre cut wire length accuracy based on the client’s provided specification sheet

- We sign a quality inspection report, once the accuracy of this initial test batch is confirmed

- A manager approves the project and the wire is set to be cut; approximately 500 pieces at a time

Hook Up Wire Service Options

WesBell Electronics is your one-stop source for hook up wire and comprehensive preparation services for pre cut hookup wire, including pre cut wire lengths and wire stripping, hook up wire spiral striping, wire twisting, and wire and cable tin dipping.

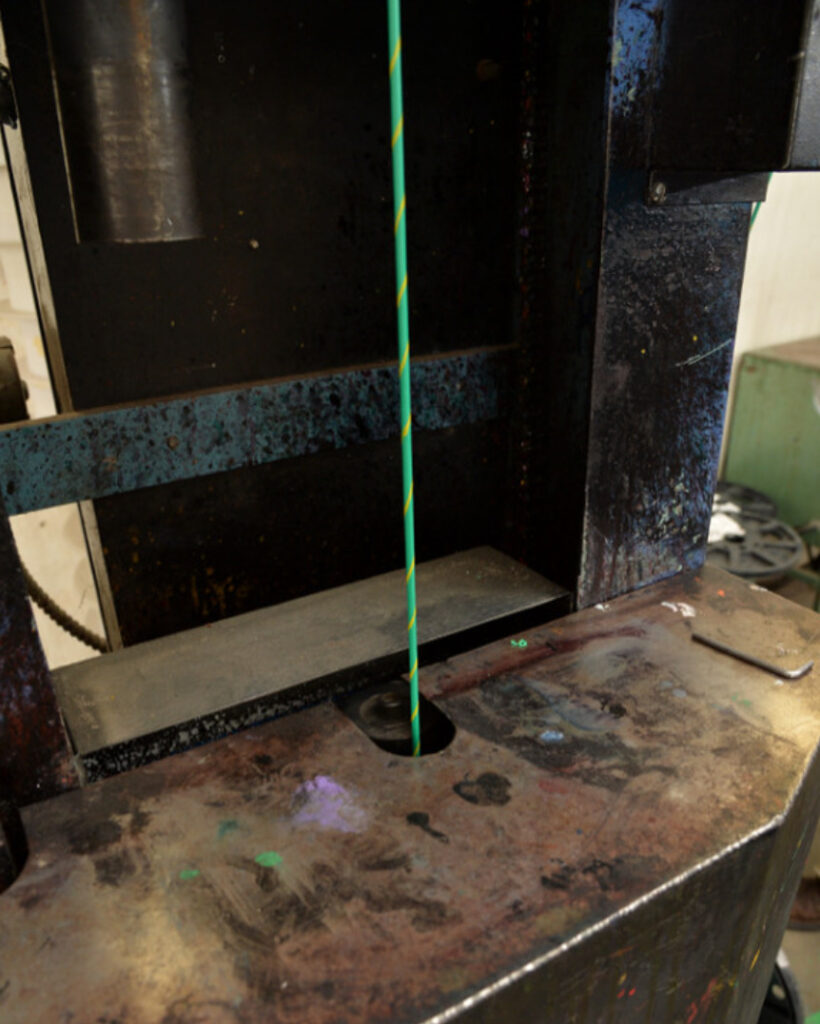

The Right Equipment Prepares Quality Hook Up Wire for Your Projects

Our dedicated team of WesBell technicians maintains the quality equipment and tools that our clients depend upon for accurate cutting and stripping preparation of their chosen hook up wire. Each wire cutting machine is precisely calibrated to capture the exact length of the wire along with the strip length on each end. The range of gauges on each machine are calibrated with the American Wire Gauge (AWG) system, ensuring efficient and accurate preparation of your hook up wire to your unique specifications and conducting your desired current-carrying capacity.

The Difference Between Semi-Strip and Full Strip and Tin Services

All copper wiring and hook up wire that’s intended for use in electrical or electronic products must ultimately be attached electronically to an application in order to transmit current. We start by asking a client how much insulation they require us to strip off the end of the wire in order for them to successfully solder, crimp or attach the wire to their application.

- The semi-strip service option slightly detaches the insulation but keeps it on the wire to avoid the risk of fraying during transit. It’s easy for copper strands to fray when they bounce around; therefore it’s critical to maintain a “slug”, or piece of insulation, attached to the wire.

- The full strip and tin option is a popular option for clients who seek to attach hook up wire, typically UL1007 or UL1015, to their application via the soldering process. In this case, WesBell technicians will first cut the wire on the wire cutting machine by setting it to full strip the insulation at 0.25-inches on both ends. Next, the copper strands are dipped into 99% lead-free tin (also referred to as solder).

- The additional process of tinning accomplishes two important objectives:

- It prevents the strands from fraying

- It enhances the adherence of solder during application. Tinned wires, whether solid wires or stranded wires, and known as the copper conductor of electricity, will slightly melt when new solder is applied, thereby melding the two much quicker and easier than without the additional tin.

Factors that Affect the Price of Cutting and Stripping Hook Up Wire

Initial factors that influence the cost of cutting and stripping hook up wire include the cost of purchasing these machines, tools and accessories:

- Wire Cutting Machine

- Wire Cutter and Wire Stripper

- Wire Straightener

- Blades and Other Accessories

The initial investment in these tools and equipment can cover more than 20 years of use, depending on the speed of technological advancement.

Once the wire or cable product is ready for the machine or equipment, other factors that may affect the price of any project include:

- Initial machine setup, including testing of products to measure accuracy and calibrate the machine

- For projects that only require semi-strip of hook-up wires, the machine will complete the process using one setting, and the product will move to an assembler that will bag, label and box the wires

- If the customer requires the wires to be fully stripped and tinned, then the wires move to the tin dipping process once they are cut

- Upon a final inspection and manager approval, the parts are bagged, labeled and boxed for shipment

The Process of Cutting and Stripping Electronic Cables

The service of cutting and stripping electronic cables involves these steps:

- The cable is cut with a cutting machine or hank wheel, depending on the overall cable length desired

- The hank wheel coils the cable into circles and secures it with a plastic zip tie or bread tie

- The outer jacket of the cable must be removed to a certain degree, and each conductor must be stripped of its insulation

- An additional service sometimes involves removing a foil or braid shield

Further optional service steps include:

- Individual conductors may be tin dipped after stripping the insulation off from each end

- Heat shrink tubing, which works like a hair dryer with a more powerful heater, may be applied to cover the area between the cut outer jacket and conductors, for cleanliness or added protection.

Advantages of WesBell Wire Cutting and Stripping Services

Our small business clients – ranging from independent producers to firms or distributors with 20 or fewer employees – frequently provide us with testimonials about how a partnership with WesBell enhances their business. Our team is proud to produce quality hookup wire, multiple wire harnesses, and cable assemblies that enable our clients to produce components that power a variety of electronics and electric devices.

3 Key Benefits of Working with WesBell for Small Businesses

- Save time with automated versus manual hookup wire preparation

Our machines can precisely cut and strip your hookup wire – and perform other comprehensive services such as spiral striping, twisting, and tin dipping – in much less time than it would take you to do it yourself. - Increase accuracy with consistent preparation of hookup wire

Our specialized tools and the AWG gauge systems on our cutting machines are precisely calibrated to deliver accuracy in the preparation of your hookup wire. You’ll find no better cutter or stripper than our team of qualified cutters and strippers at WesBell Electronics. - Reduce waste with quality control of hookup wire services

By design, excellent quality control ensures the reduction of waste, which ultimately leads to overall savings of time and money.

Industries That Benefit from WesBell’s Cutting and Stripping Services

WesBell wire is incorporated into thousands of products across different industries. Our hookup wire, wire harnesses, cables and cable assemblies support industries including art, automotive, business, commercial, education, media, music, recreation, regulation, and more.

Manufacturers of Components or Parts

Many of our clients build parts and components that are ultimately incorporated into other or larger products for the industries they serve. For example, we provide wire harnesses to companies that manufacture odometers for the automotive industry; we provide hook up wire twisting services for a manufacturer of solar panels and equipment; and we provide a host of wire assemblies for a client who manufactures 3D Printers.

Manufacturers of Commercial Scales

We cut cables, clean the jacket and shield, strip wires and tin each end for a commercial scale manufacturer to incorporate into their scales. The cable we produce is ultimately installed underground, and enables trucks to be weighed on highway weigh stations.

Manufacturers of Electrical Kits for Academic Use

We cut and strip the wire that a customer incorporates into the small electrical kits they manufacture, that are designed to teach high school students about electricity.

Microphone Manufacturers

We provide and prepare cables for a firm that builds microphones for media reporters. We cut 5-foot cables in multiple colors to match skin tones, and then cut, clean, strip and solder the cables.

Turntable Manufacturers

We provide and prepare wire harnesses to a company that manufactures turntables for music industry disk jockeys. We pre cut hook up wire, press-crimp the terminals, add sleeving and connect to plastic housing on each end.

Fountain Manufacturers

We cut large extension cords and crimp terminals on one end for a firm that manufactures bird feeder fountains that are ultimately installed in yards and open areas. This special cable is designed for outdoor and underground use.

Manufacturers of Vibration Monitoring Equipment

For a client that manufactures vibration monitoring equipment that is ultimately installed into dams to monitor vibration levels, we provide and prepare cable assemblies that connect to electronic components by cutting and stripping the cable, and tin dipping the conductors.

Non-Electrical Cut Wire Clients

Artists often use copper for making jewelry, stained glass and more:

- Copper Wire for Jewelry: Some creative customers order bare copper wire cut to length, which enables them to create necklaces, bracelets and earrings.

- Copper Wire for Stained Glass: Some clients use bare copper for stained glass projects because it molds well as the curved lines/barriers between colors.

- Copper Wire for Creative Projects: Handles for baskets and bird feeders may also be designed from copper

Answers to Frequently Asked Questions about Pre Cut Hook Up Wire and Wire Stripping Services

What is American Wire Gauge (AWG)?

- American Wire Gauge (AWG) is a standardized system of wire conductor sizes for non-ferrous wire, primarily including copper, as well as aluminum and some other materials. The word “gauge” refers to the diameter of the wire. The cross-section of each wire’s diameter is used to help determine its current-carrying capacity. The AWG system has been used since 1857 in the United States and Canada, and is also referred to as Brown & Sharpe wire gauge.

What makes each type of hook up wire different?

- For each of the eight types of WesBell hookup wire available online, the type and design of the insulation coating of the copper wire is what differentiates one type of wire from another. The insulation specifications for each type of wire determine the voltage and temperature capacity of the wire.