Apr 7, 2022

Guide to Electrical Wire Insulation: Why It Is Important

The importance of insulated wiring cannot be overstated. It protects your wiring from damage and from the hazards it causes to the environment around it. This guide covers various electrical wire insulation types, why insulation is crucial, and how to choose the best materials for your specific needs.

Why Do You Need to Insulate Wires?

You may know wire insulation’s importance but not exactly why it’s so essential. Here are key reasons why insulating wires is critical:

1. Safety

Electrical wire insulation is essential to keeping an area safe and helping individuals avoid electric shock. The Occupational Safety and Health Administration (OSHA) considers exposed wires, worn insulation, and removed insulation electrical hazards. The risk of shock increases in wet conditions, from bathrooms to rain.

2. Durability and Protection

Wiring is made of metals that can corrode with exposure to water. Insulation protects materials like copper and steel from exposure to the elements to withstand their surroundings and last longer. If wiring wasn’t insulated, it wouldn’t last as long or as effective. Though no material can perfectly insulate a wire, any insulation is better than none.

3. Leakage Prevention

Electrical leakage occurs if energy transfers to components like a framework or other wires. Insulation protects wires from touching each other and from contacting framework or grounding components. That ensures an electrical system functions properly.

4. Color-Coding

Electrical wires are color-coded to certain standards for consistency. That helps electricians and others handling wires understand wire function and its voltage. Color codes allow for quick identification, making wiring jobs simpler. You might see colors like:

- White insulation denotes 14-gauge wires rated for 15 amps.

- Gray insulation denotes cables rated for 15 amps.

- Black insulation denotes six- and eight-gauge wires rated for 40-60 amps.

- Orange insulation denotes 10-gauge wires rated for 30 amps.

- Yellow insulation denotes 12-gauge wires rated for 20 amps.

Best Materials for Electrical Insulation

There are various electrical wire insulators. Within that variety, three major categories break down into more specific styles.

Plastics

There are many plastic insulation methods, most commonly used polyvinyl chloride (PVC). Wires insulated with PVC can withstand acids, solvents, gas and ozone. There are other forms of plastic insulation, as well:

- Polyethylene (PE): This type of insulation is often used on coaxial cables. PE is flammable, so it should be kept away from hot surfaces. It is a great option for cables that require high-speed transmission. PE is not flexible, which is important to keep in mind when choosing an insulation material.

- Polyurethane (PUR): Flame-retardant PUR can withstand a wide range of temperatures, making it great for insulating wires in areas where it needs to be tough and flexible. It is a good choice for low-temperature military needs and applications near salt-contaminated moisture.

- Chlorinated polyethylene (CPE): This material commonly insulates power and control cables and is often found in industrial power plants. This is a cost-efficient as well as flame- and chemical-resistant option.

- Nylon: This is a great choice if you need flexible insulation. Despite being flexible, nylon is tough and resistant to chemicals, cutting, and abrasion.

Fluoropolymers

Fluoropolymers are characterized by their high resistance to solvents, acids and bases. They are often used in cars and planes because of their unbeatable chemical and temperature resistance. Several types of fluoropolymers have various advantages of their own:

- Perfluoroalkoxy (PFA): PFA is an incredibly electrically efficient option as it has very low dissipation. It comes at a greater cost but has incredibly high-temperature ratings.

- Polytetrafluoroethylene (PTFE): PTFE is a synthetic material resistant to water, oil, chemicals and heat and has an incredibly high temperature rating, as well.

- Fluorinated ethylene propylene (FEP): This material is commonly used to insulate plenum cables and is often used in military contexts. It has quality processing characteristics and can be used for various applications.

- Ethylene tetrafluoroethylene (ETFE) and ethylene chlorotrifluoroethylene (ECTFE): Through irradiation, ETFE and ECTFE become thermoset. Compared to PFA and FEP, this material is more flexible and strong.

- Polyvinylidene fluoride (PVDF): PVDF typically comes at a low price, making it used throughout various industries. It also has many benefits, such as being flexible, lightweight, thermally stable and resistant to chemicals, weather, abrasion, heat and fire.

- Thermoplastic elastomers (TPE): TPE is made from a mix of polymers. It is often used in both automotive and household appliances.

Rubbers

Rubber is a great choice for electrical insulation as it does exactly what the goal of insulation is — keep electricity confined in the material. Like the other materials, there are a variety of types of rubber:

- Thermoplastic rubber (TPR): This material has good colorability, high processing speeds and a wide usable temperature range. It will protect the wire from curing even against heat, weather and age.

- Polychloroprene or neoprene: Neoprene is a synthetic thermoset rubber. Unlike TPR, it is cut-through resistant. It is also abrasion-, oil- and solvent-resistant. It is known for its long life and its ability to stand up to a wide range of temperatures. Neoprene can also be self-extinguishing.

- Styrene butadiene rubber (SBR): SBR has a wide temperature range and is normally used to insulate Mil-C-55668 cables.

- Silicone: Silicone is a classic option. The material is heat-resistant and flame-retardant. It also provides a level of flexibility that is helpful for cables being installed in tight places.

- Fiberglass: Fiberglass is a common choice in places where it needs to withstand extreme temperatures. Due to its resistance to moisture and chemicals, it is most often used for heat-treating, kilns, foundries, and various applications throughout aluminum processing.

- Ethylene propylene rubber (EPR): Another rubber with a wide temperature range, EPR is thermal and electrical. It is most often used in high-voltage cables. It is resistant to heat, oxidation, alcohol, alkali, weather, water, and acid.

- Rubber: Traditional rubber provides low-temperature flexibility and resistance to water, abrasion, and alcohol.

- Chlorosulfonated polyethylene (CSPE): CSPE, sometimes called Hypalon, works in low-voltage situations and is resistant to UV rays and chemicals. This makes it a good option for outdoor cables and wires. It is often used in appliances.

- Ethylene propylene diene monomer (EPDM): This rubber material also has a wide temperature range and remains flexible regardless of the temperature it is exposed to.

Different Electrical Cable Types

There are a lot of electrical cables out there. Knowing which one you need for your project can then help you understand what insulation cables come with or what insulation you’ll need to use. Here are some common cables you might be using in your projects.

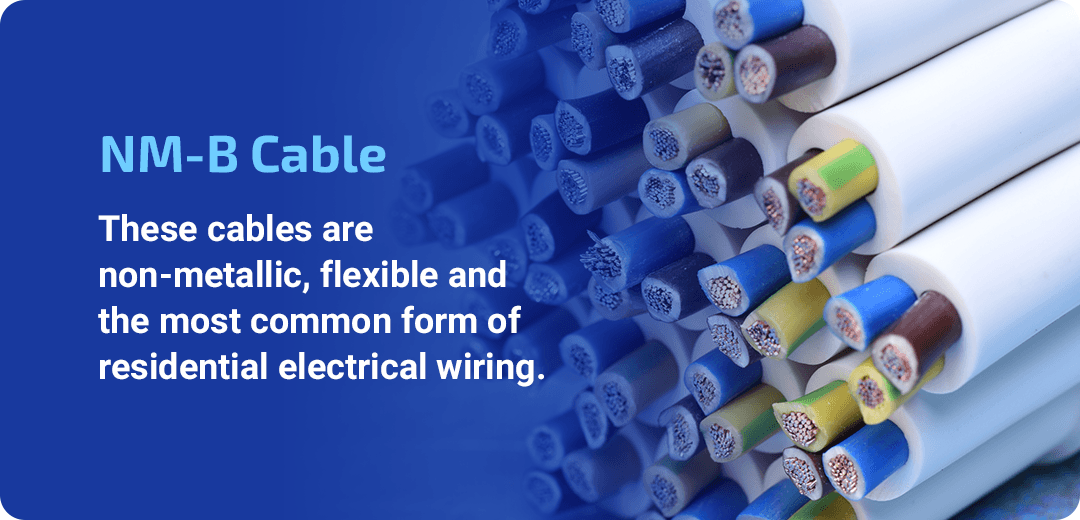

NM-B Cable

These cables are non-metallic, flexible, and the most common form of residential electrical wiring. The NM-B cable is only meant for indoor use without exposure to moisture or direct heat. It should not be run outside of the walls but rather behind them or inside floor cavities or ceilings. These cables are commonly used within a building to run power to lights and appliances. NM-B cables are often insulated with polyvinyl chloride (PVC) or rubber.

UF Cable

The UF in UF cable stands for underground feeder. These cables are best installed in-ground or other damp areas. They are embedded in a group in solid thermoplastic. They are very similar to NM-B cables but are best for underground burial. They can also be used in certain indoor settings. UF cables may have color-coded PVC or nylon insulation.

Metal-Clad Cable

These cables are used in residential, commercial, and industrial settings. Metal-clad cables, or MC cables, are also used for indoor and outdoor applications. When wrapped in copper, our 16-awg option allows them to serve a wider variety of purposes, like overhead transmission and distribution.

SE-R Cable

The SE-R cable can be used in panel feeder and branch circuit applications. It is made with materials that make it sunlight- and water-resistant as well as flame retardant. This allows it to be used both indoors and outdoors, though if used outdoors, it should not be buried directly without conduit. You’ll find SE-R cables with nylon insulation.

USE-2 Solar Wire

The USE-2 solar wire has been needed more in recent years as renewable energy and solar power become increasingly common. This wire is rated for various environments but is most commonly used in photovoltaic power and underground. USE-2 wire can come with flexible, sunlight-resistant rubber insulation.

What Type of Wire Insulation Is Best?

The answer to this question will vary with your application. Each type of wire insulation provides unique benefits, and each one works best in a unique situation. Here is a breakdown by situation of what wire insulation is best to choose.

Flammable Areas

In situations when temperatures get very high and there is a risk of fire igniting, certain materials are best to insulate your wires. Polyvinyl chloride (PVC) and semi-rigid PVC are good plastic materials. If you are looking for a rubber insulator, neoprene polychloroprene can be made flame-retardant and self-extinguishing. Silicone is also a good flame-retact rubber option. Of the fluoropolymer options, FEP and PVDF are flame-resistant.

Outdoor Areas

If you are installing cables and wires outside, some materials are much better suited to withstanding nature. CPE is weather-resistant plastic insulation. As for rubber, TPR, EPDM, and EPR are good options. Your best fluoropolymer option is PVDF.

Wet Areas

Many insulation materials do not stand up well against water, so if you are insulating in an area that could get wet, it is important to choose the right material. Polyethylene and semi-rigid PVC are the best plastic options. All rubber options will stand up well to water, but EPR is an especially good choice. Of your fluoropolymer options, PTFE has good water-resistant properties.

Chemicals

If you are wiring in an area that will be exposed to chemicals, you need to choose an option that can withstand them. Plastic options like polyurethane and nylon will provide good chemical resistance. Fiberglass and CSPE are good rubber options with chemical resistance. Fluoropolymer insulation with chemical resistance includes PTFE and PVDF.

Low-Temperature Areas

Polyurethane is a good plastic choice for a low-temperature environment. Most rubber materials will hold up well in low-temperature environments. For fluoropolymer, PFA can withstand low temperatures well.

How Do You Choose?

All the options available to you may seem overwhelming. Here are the factors you need to consider when thinking through which type of insulation to choose:

- Electrical properties: Knowing the electrical properties of the insulation material will help you determine what type to choose. This includes dielectric strength, insulation resistance, charging current, arc resistance and tracking susceptibility.

- Mechanical properties: It is also important to know each insulation material’s toughness, flexibility, tensile strength, elongation and crushing strengths, resistance to abrasion or moisture, and brittleness.

- Chemical properties: Know how well your insulation material can absorb moisture, its resistance to oil, gas, acids and alkalis, and its stability when exposed to sunlight, ozone or flames. Knowing these and the external factors around the place you are wiring will help you decide.

- Thermal properties: Your insulation material’s thermal properties, such as contraction and expansion, flow and softening temperature, and compatibility with operating and short circuit conditions, are important.

Doing your research before you insulate your wires on your insulation material and the wiring circumstances will ensure you provide your space with the safest option, protecting both you and your wiring.

Shop WesBell Electronics for Insulation Wire

WesBell Electronics has been around since 1988 when we began as a distributor of flexible cables and hookup wire for contract manufacturers, OEMs and maintenance and repair organizations. Since then, WesBell has added services to go along with our products.

We want you to get what you need as fast as possible and strive to get our production orders out within two to three weeks of you placing the order. We also offer free shipping on orders over $500. Throughout the process, our customer service is here to help you make the best choice for your needs. WesBell strives to save our customers time and money. Contact us today with questions or to learn more about how we can give you the best experience possible.