Apr 13, 2021

Shielded vs. Unshielded Fire Alarm Cable

Fire alarm cabling has shielded and unshielded options. Choosing the incorrect model could raise the price of an electrical job beyond the budget or cause electromagnetic interference problems. Choosing whether to use cabling with or without shielding is one of the most important decisions when choosing parts for a fire alarm system.

What Type of Cable Do You Use for Fire Alarms?

Standard types of wiring or cabling do not suffice for fire alarms. Various fire alarm cable constructions offer different degrees of heat and melting protection. Options include power-limited (PL) and non-power-limited (NPL), but the latter is less common.

Power-limited options are connected to power supplies that limit the voltage and power going through the cabling. To comply with National Electrical Code (NEC) 760.121, the power supply used with PL fire alarms (PLFA) should be either a transformer or power supply specifically listed for use with PLFA or a class 3 design. When not using a separate power source, PL fire alarms must have their own branch circuit that does not have ground fault circuit interrupter (GFCI) or arc-fault circuit interrupter (AFCI) protection.

Non-power-limited fire alarms (NPLFA) do not need limiting from their power source and operate up to 600 volts. As noted, this type is less commonly used. At Wesbell Electronics, we specialize in the more common power-limited types of fire alarm cabling.

Other categories of cabling include ones with applications such as riser cables or plenums. Firepower-limited riser cable (FPLR) only moves between floors or up walls to connect fire alarms. This type of cable costs less than the type used in plenums, but it is not approved for use in areas exposed to environmental air.

Cabling for use in plenums (FPLP) allows the installer to install it in air ducts, attics, and other enclosed, horizontal spaces. The difference between FPLP and riser cable is the amount of insulation. In horizontal spaces, fire can more readily spread. The cabling used in these areas needs extra insulation to protect it from heat damage and melting than the type used in rising areas.

Another consideration for fire alarm components is the size of the cabling and the number of conductors inside. These range from two conductors to eight and gauges from 22 to 18. Conductors inside the cabling are solid copper wires. While the NEC allows for either stranded or solid copper wires with PLFA circuits, solid conductors are more readily available.

The last categorization of fire alarm cabling is shielded versus unshielded. The main difference between these options is whether they offer protection against electromagnetic interference (EMI).

What Are Shielded and Unshielded Cables?

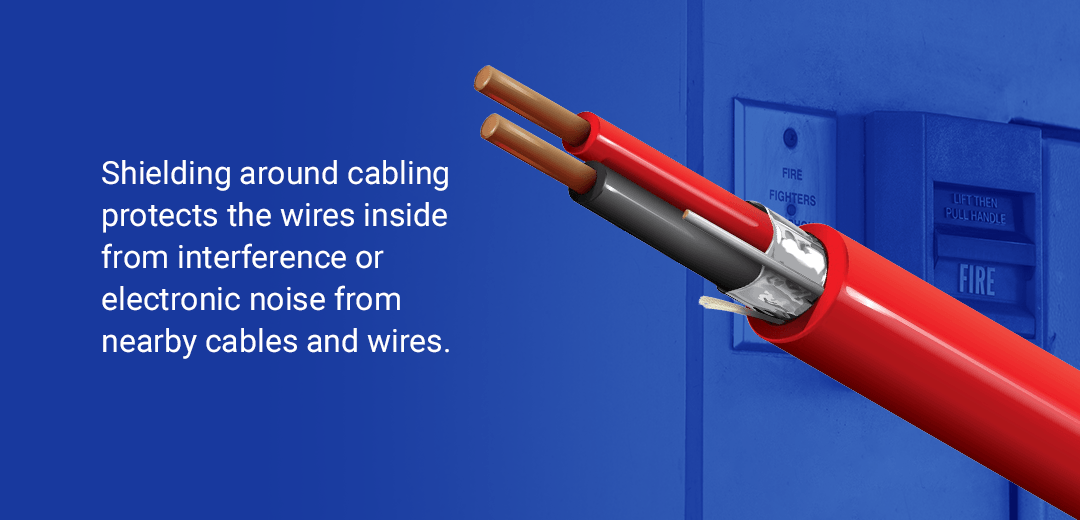

Shielded and unshielded are terms for different coatings on the exterior of cabling. While fire alarms can have these options, other types of cabling, such as signal and data cables, also have them. When needed, the shielding provides valuable protection from EMI that could impact connections, cause cross-talk between cables, and reduce radiation from electromagnetic waves.

Difference Between Shielded and Unshielded Cable

Wires are the components that fit inside the cable. Typically, only the entire cable does or doesn’t have shielding. Some designs require the wires inside the cabling to have individual shielding or shielding wrapped around wire pairs. This application of wire shielding may be necessary in cases of heavy exposure to excessive EMI noise or to prevent cross-talk between wires inside the cabling. Generally, the shielding consists of an aluminum polyester foil surrounding the wires inside the cabling. But you can special order braid or foil and braid shielded cabling for fire alarms. Braided shielding makes terminating the cabling easier. By using foil-braid shielding, you get the benefits of foil coverage and the advantage of the ease of termination from the braiding.

Type of Shielding Used for Cabling

Shielding consists of a form of conductive wrapping, typically aluminum or a similar metal. The conductive shielding blocks outside electromagnetic radiation from interfering with the signals passing through the wires inside the cable. The shielding also protects other cables nearby from EMI caused by the wires inside.

The shielding’s design determines the amount of noise the cable has protection against, which ranges from 85% to 100%. Several shielding designs exist, with common options including braided and aluminum foil shields.

Braided shields start with copper wires braided around the conductors. The sizes and angles of the wires used for the braiding depend on the size of the conductor. Generally, smaller wires woven at tighter angles will produce greater flexibility in the cable.

You must minimize the wire’s flexing and movement to maintain the shielding’s integrity. Braided shielding can offer up to 90% filtering of EMI. This shield does not protect 100% because microscopic gaps between the braids can allow EMI to pass through. As long as the cabling stays still, the 90% shielding should suffice.

Foil offers 100% coverage of the wire inside, but this option is less durable and more challenging to work with than braided shielding. But the 100% shielding on cabling better protects against interference that could prevent signals from moving between fire alarms.

When choosing the type of shielding, note that braided coating or braid-foil cabling costs more and requires a special order. Braided shielding makes the cabling easier to work with because it is less likely to sustain damage when running the cabling. Plus, you can more easily create terminations with this type of shielding.

Foil coating is the standard option for shielded cabling. It costs less than braided shielding but provides 100% coverage of the conductor inside the cable. The downside to this type of shielding is the chance for the foil polyester coating to break when used in environments that require a lot of flexing to get the wires into place. Foil shielded cabling also makes creating connections more difficult due to the thinness of the foil compared to braided shielding.

Should Fire Alarm Cable Be Shielded or Unshielded?

Using shielded or unshielded cabling for a fire alarm depends on the area you run the cabling in and the manufacturer’s requirements. Always check the manufacturer’s specifications for cabling size and shielding options first.

Fire alarm systems are built around a specific wire size, making that the first and most important decision. Some manufacturers may indicate whether or not to use shielding with the cabling in the system. If you cannot find this information, use other parameters for when to use shielded or unshielded cabling.

If fire alarm cabling does not have other wires or cabling nearby or other sources of electrical interference, you may not need shielding. But in facilities near heavy electrical or mechanical equipment, the interference from these devices might mean you should use shielding to protect the fire alarm cable.

Choose shielded fire alarm cable when other wires or cabling run near those supplying the fire alarm. You should also use a shielded option in any area with a lot of electronic equipment or machinery, which could also produce EMI. When used appropriately, this type of covering will ensure clear signals are delivered through the wires in the fire alarm cabling. It can also prevent false alarms or incorrectly sent trouble signals.

Unshielded fire alarm cables offer the same heat resistance as their shielded counterparts but lack the added EMI protection. Shielding can increase the cost of the product due to more components and processing. When you need shielding, though, do not skip this protection. Doing so could cause operational problems for the fire alarm.

Does Cable Shielding Increase Heat Protection?

The shielding in fire alarm cable does not provide additional heat protection. The insulation and jacket create cabling that is more resistant to heat damage.

Choose the heat protection level based on where you will lay the cabling. Plenum cabling has a greater ability to resist heat due to its placement in locations where fire can spread. Never use riser cables in areas that require plenum options. Doing so will cause a code violation and possibly compromise the ability of the fire alarm system to function in case of a fire.

Fire Alarm Cable Conduit Requirements

The code for installing fire alarms requires conduit in specific situations, regardless of whether you use shielded or unshielded cabling. The locations where you install the cables determine whether you need conduit or raceways.

NEC 760 requires using rigid nonmetallic conduits or metal raceways for running cabling through walls or floors. Additionally, you need electrical metal tubing or intermediate or rigid metal conduit when running fire alarm cabling through elevator shafts. These measures ensure vertically running pieces have adequate support to remain intact and protected from external damage. The presence of shielding does not allow the omittance of using conduit where required by code.

Running Fire Alarm Cabling to Meet Code Requirements

For the cabling to meet code standards, whether shielded or unshielded, it must follow several guidelines for placement and protection.

First, remember to protect against fire spread and damage when installing fire alarm components. For example, when passing cabling through a fire barrier, you must use a metal raceway or nonmetallic conduit and fire caulking to preserve the wall’s fire-blocking purpose.

When using power-limited fire alarm circuitry, you cannot attach the cabling to the outside of existing raceways. This type of cabling requires support directly from the building’s structure. The ties, straps or hangers used to connect the cabling to the building must not damage the fire alarm cabling.

Use connectors with similar shield ratings to provide complete protection when using shielded cabling. Also, ground one end to avoid creating noise loops within the cabling. While you should ground one end, do not allow the shielding to contact metal raceways or other metallic components of external structures. If you fail to connect shielded cabling properly, you may create a ground fault in the system.

Guidelines permit running power-limited fire alarm cabling through cable assemblies or communications raceways. Match the assembly or raceway to the type of cabling used. For instance, plenum raceways or assemblies go with FPLP, and riser correspondents with FPLR. When any fire alarm cabling leaves a raceway, use bushings to support and protect the cabling.

Be sure to check any local requirements for installing fire alarms and their circuitry. Some cities or states have stricter standards than those outlined by national codes.

Do Fire Alarm Cables Need to Be Segregated?

Segregating fire alarm cables is a component of the National Fire Protection Association (NFPA) 72 code for fire systems and is outlined in the NEC 760. For safety reasons, the NFPA 72 requires the separation of non-power-limited fire alarm circuitry from communications wire by at least two inches. While the NFPA and the NEC don’t address separation to prevent electromagnetic interference, many fire alarm manufacturers account for this in their instruction manuals.

When setting up fire alarm cabling, know whether it is class 1, 2 or 3 circuits based on the power going through it. Class 1 circuits carry between 120 and 600 volts. This classification has the most restrictions for separating the cabling from other types of wires. Class 2 circuits are very low voltage, carrying less than 30 volts and less than 100 VA. For voltages between 30 and 150 volts, the power must not exceed 0.5 VA. Lastly, class 3 circuits include those with voltages over 30 and power up to 100 VA.

When placing power-limited class 1 circuits for a fire alarm, you cannot place the cabling in the same raceway as other class 1 circuits, electric light wiring, or power cables. If placing a barrier between the electrical conductor and the power-limited fire alarm cabling, you can place the two beside each other. When not in raceways, any type of PLFA cabling — shielded or unshielded — always needs at least two inches of distance from electrical conductors, power cabling or other class 1 circuits.

With classes 2 and 3, the lower power carried through these types of cabling means they have fewer restrictions on their use. Both class 2 and 3 PLFA circuits can be in the same tray, enclosure, raceway, assembly or cable as low-power broadband, communications circuits or other fire alarm circuits. However, the class 2 insulation must meet the requirement for class 2 PLFA insulation. The only exception to the types of cabling allowed with class 2 and 3 PLFA circuits is audio system circuits. These cannot be in the same enclosure, cable assembly, tray or raceway as the PLFA circuits.

Shielded vs Unshielded Fire Cable Price

Shielding can increase the cost of fire alarm cables due to more components and processing. When you need shielding, though, do not skip this protection. Doing so could cause operational problems for the fire alarm. Comparing prices between shielded and unshielded options can help determine which type is more cost-effective for your specific application.

Find Shielded and Unshielded Fire Alarm Cable and More at Wesbell Electronics

To save money with an unshielded or shielded fire alarm cable to protect against electronic noise, find all the cabling you need to connect the fire alarms at Wesbell Electronics. Our company has three decades of experience supplying wires, multi shielded cables, assemblies and more to our customers. Trust us for your cabling needs for your commercial-grade electrical projects. If you need a quote, have questions or need cabling for a custom project, contact us today.