Oct 2, 2017

PVC Multiconductor Cables Explained

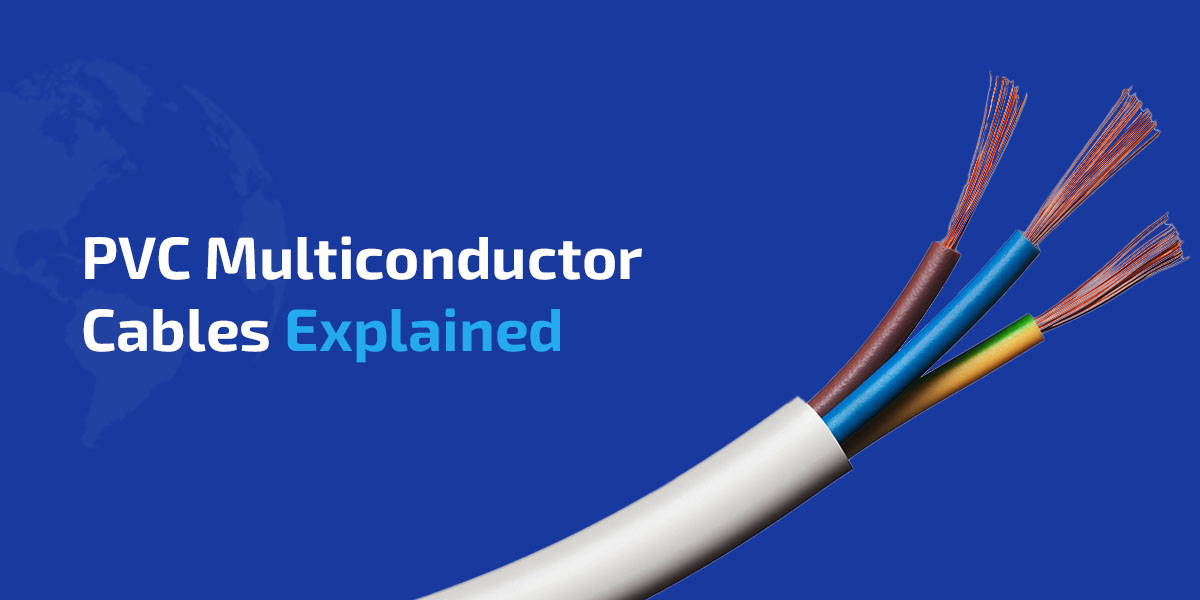

Several different types of electrical cables exist, including polyvinyl chloride multiconductor cables. These unique, stranded cables are vital components in signal and power transmission within modern industries.

They consist of multiple individually insulated conductors, often made of copper, bundled together within a single outer thermoplastic PVC jacket. The PVC and additional shielding provide consolidated, organized and easy-to-use wiring with added protection and insulation against impact, heat, moisture, chemicals, voltage and electromagnetic interference.

To help you better understand the nature of PVC multiconductor cables and whether they are suitable for your application, let’s discuss multiconductor cable applications, their makeup and characteristics. If your company requires quality multiconductor electronic cables, including shielded and unshielded or for specialized applications, it is wise to know what PVC multiconductor cables offer.

Applications of Multiconductor Cables

PVC multiconductor cables offer neat and streamlined wiring, facilitating quick installation and convenient maintenance. Multiconductor cable applications apply to various industries, including manufacturing, automation and telecommunications. This type of multiconductor cable is highly effective for data transmission, medical electronics, audio and sound applications and computer peripherals, among other typical applications.

Where to Use Shielded PVC Multiconductor Cables

Shielded PVC multiconductor cables have metallic foil or braided strands sheathed in a PVC jacket. They are ideal for use in environments where there is a possibility of electromagnetic and radiofrequency interference.

The equipment that uses shielded multiconductor cables tends to be sensitive and surrounded by potential interference. Though shielded PVC multiconductor cables are more expensive, their pertinent uses include:

- Security network systems

- Data centers and systems

- Telecommunication infrastructure

- Radio and recording studios

- Medical equipment

- Communication hubs like airports

- Industrial automation systems

Where to Use Unshielded PVC Multiconductor Cables

Unshielded PVC multiconductor cables offer a cost-effective, reliable solution in instances where interference is less likely to occur. Though they have the standard PVC outer layer, there is no additional protection against interference. You would use this cabling in low-risk areas such as:

- Home local area network systems

- Small office networking

- Low-traffic networks

- Home or small building security systems

- Low-voltage power supplies

PVC Multiconductor Cable Layers

PVC multiconductor cable has convenient attributes and characteristics that make it resilient, flexible and space-saving. You can run one stranded cable containing an array of specialized conductors instead of individual wires. To help you better understand these cables’ makeup, here is a breakdown of the multiple layers that compose them.

Several different types of electrical cables exist, including polyvinyl chloride multiconductor cables. These unique, stranded cables are vital components in signal and power transmission within modern industries.

They consist of multiple individually insulated conductors, often made of copper, bundled together within a single outer thermoplastic PVC jacket. The PVC and additional shielding provide consolidated, organized and easy-to-use wiring with added protection and insulation against impact, heat, moisture, chemicals, voltage and electromagnetic interference.

To help you better understand the nature of PVC multiconductor cables and whether they are suitable for your application, let’s discuss multiconductor cable applications, their makeup and characteristics. If your company requires quality multiconductor electronic cables, including shielded and unshielded or for specialized applications, it is wise to know what PVC multiconductor cables offer.

Applications of Multiconductor Cables

PVC multiconductor cables offer neat and streamlined wiring, facilitating quick installation and convenient maintenance. Multiconductor cable applications apply to various industries, including manufacturing, automation and telecommunications. This type of multiconductor cable is highly effective for data transmission, medical electronics, audio and sound applications and computer peripherals, among other typical applications.

Where to Use Shielded PVC Multiconductor Cables

Shielded PVC multiconductor cables have metallic foil or braided strands sheathed in a PVC jacket. They are ideal for use in environments where there is a possibility of electromagnetic and radiofrequency interference.

The equipment that uses shielded multiconductor cables tends to be sensitive and surrounded by potential interference. Though shielded PVC multiconductor cables are more expensive, their pertinent uses include:

- Security network systems

- Data centers and systems

- Telecommunication infrastructure

- Radio and recording studios

- Medical equipment

- Communication hubs like airports

- Industrial automation systems

Where to Use Unshielded PVC Multiconductor Cables

Unshielded PVC multiconductor cables offer a cost-effective, reliable solution in instances where interference is less likely to occur. Though they have the standard PVC outer layer, there is no additional protection against interference. You would use this cabling in low-risk areas such as:

- Home local area network systems

- Small office networking

- Low-traffic networks

- Home or small building security systems

- Low-voltage power supplies

PVC Multiconductor Cable Layers

PVC multiconductor cable has convenient attributes and characteristics that make it resilient, flexible and space-saving. You can run one stranded cable containing an array of specialized conductors instead of individual wires. To help you better understand these cables’ makeup, here is a breakdown of the multiple layers that compose them.

Copper and Tin Layer

The copper conducts electricity, so the cable is nothing without the copper. As the strands of copper get smaller, they become more flexible, so you will sometimes see multiple thin strands used for added adaptability in the application.

The layer of tin over the copper strands limits corrosion, decreases the chances of heat problems and makes it easier to solder the wires to a surface. Adding hot solder to the wire will slightly melt the tin coating and adhere the two together well.

Insulation Layer

Each conductor of copper or group of flexible strands has a layer of insulation. Multiple small strands equal that of a solid larger strand if both diameters are equivalent. We don’t want any damage to the copper, so the insulation is the first layer of protection. In this case, the insulation will be PVC, a specific mixture of elements used to protect the copper against a certain level of heat, voltage, some liquids and environmental impact.

For example, the style UL1007 will resist 105 degrees Celsius and 300 volts, while UL1015 resists 105 degrees Celsius and 600 volts. Both are PVC insulation, but one is thicker than the other. However, as you can see, the melting point is the same in this case. Numerous insulation types resist different levels of heat, voltage, liquids and impact — as you might guess, they each get more expensive and rarer as the list of requirements gets longer.

Shielding Layer

Aluminum foil can deflect sunlight, and if you think about that concept, it will help you understand how a PVC cable shield functions. When two cables run side-by-side without shield protection, their waves can overlap, causing electromagnetic interference.

You may have experienced this phenomenon when listening to a radio that bleeds between two stations. The interference is due to the cables being too close to each other because the magnetic field is larger than the cable. So, wrapping a single aluminum polyester shield around all the conductors deflects the magnetic field inward and avoids colliding with the cable next to it.

As you understand shielding and shielded cables, you’ll see various shields work slightly differently. The most basic is a single aluminum polyester shield, which mostly looks like aluminum foil. The next level of protection uses the same material but individually wraps pairs of wires and the entire set of conductors.

Also, a braided shield uses tinned copper strands woven like a Chinese finger trap toy and wrapped around all the conductors. Finally, there is a foil and braid shield that uses both shields on the same cable for increased protection.

Jacket Layer

Imagine a multiconductor cable jacket as the outermost layer that mimics the insulation over the copper. It brings everything together as a single unit, but if you remove the jacket, you will see a shield and multiple conductors. The outer jacket’s resistance levels mimic that of the insulation because they will be in the same spot for the application.

For example, when would the jacket need to resist 200 degrees Celsius while the conductors need to resist 300 degrees Celsius? It may be rare, but there are a few circumstances when the jacket needs different approvals compared to the insulation. For instance, when the cable runs 100 feet from the inside of a house to a barn, the portion that runs outdoors will need additional protection from either sunlight or underground elements.

Attributes of Shielded PVC Multiconductor Cables

You should know what wire attributes to consider before buying. Let your supplier know you need a wire that resists a specific temperature, voltage, liquid or environmental condition. They will find you the most cost-effective option that fits your requirements.

Wire harnesses are in ovens, near car engines, in radios, inside your home, in your computer, cash registers, telephone poles and various other applications. So, there might be a long list of things to resist, and every wire and cable specification sheet lists its precise details.

If you have a requirement that didn’t make it to the specification sheet, you can ask the design engineers at the manufacturer’s facility to respond.

Characteristics of Shielded PVC Multiconductor Cables

Believe it or not, colors matter. Some equipment manufacturers look beyond the cable’s functionality and need the outer jacket to be white to match the entire desktop computer. Some need the cable to be orange for safety reasons. Some harnesses are specific about the color combinations of each wire, different from the standard colors used in the industry. Some applications need a smaller-than-normal outer diameter to fit inside their application.

Higher design costs, new materials and the expense of a minimum run can usually meet these characteristics. To change the jacket color to orange, the manufacturer must buy that material, take the current job off the machine, test and approve the orange cable to the matching specifications and then complete a limited run. The project might take more time and money, but it is doable!

Choose WesBell Electronics as Your Preferred Multiconductor Cable Supplier

At WesBell Electronics, we have been a family-owned and -operated business since 1988. We understand the industry and our valued clients’ product and service needs. We distribute and assemble wire and cable and supply quality multiconductor electronic cables and various others, such as hookup and electrical wire. Additionally, we offer a range of comprehensive services to ensure the wires and cables are ready for installation once you receive them. We also hold an ISO 9001/2015 certification as a promise of our dedication to meeting quality and regulatory requirements.

Start the process and contact us online today or call us toll-free at 800-334-8400 to place an order or to seek advice on everything related to wire, cable and tubing.