Sep 14, 2022

What Is Hook-Up Wire?

Hook-up wire, lead wire, high-temperature wire, automotive wire and electrical wire are all broad terms describing certain types of single-conductor wire. Learn about common types of hook-up wire, their uses and what to consider before purchasing the wire for your applications.

What Is Hook-Up Wire?

Hook-up wire is a type of wire used in low-current, low-voltage applications, like an enclosed piece of electronic equipment. Each type of hook-up wire varies in terms of conductors, insulation materials and voltages — making it crucial to consider the requirements of your application to choose the best one.

Hook-up wire uses smaller American Wire Gauge (AWG) strands. As a result, it tends to be more flexible than electrical wire, making it perfect for electronic equipment.

You can find these wires in:

- Control panels

- Automotive tools

- Switchboards

- Ovens

- Electronic circuits

- Internal computer wiring

- Home and office appliances

Hook-up wires work with different components as the rated voltage, conductors and insulation material differ.

Uses and Benefits

Hook-up wires are great for low-current and low-voltage applications. These wires go with devices and appliances to connect to components, including:

- Capacitors

- Transistors to a power source or each other

- Resistors

You will commonly find wires in the automotive and aerospace industries, where they serve as wiring harnesses. They are available in various colors and materials and suit several applications.

You can expect many benefits when working with hook-up wires, such as:

- Superior thermal conductivity

- Excellent electrical conductivity

- Insulated with Polyvinyl chloride (PVC) coating to protect against abrasion and chemicals

- Highly resistant to corrosion

- Reduces the need for repetitive and costly replacements

- Malleable and can be shaped without snapping

Common Types of Hook-Up Wire Materials

For the insulation of materials for hook-up wires, there are various materials you can find:

- PTFE: PTFE is a tough, non-aging, abrasion, weather-resistant and high-temperature-resistant material. The 600-volt-rated single conductor wiring is made with polytetrafluoroethylene insulation. The PTFE material is ideal for internal wiring of electronic appliances and equipment.

- PVC: The most common jacketing material for electronic cable, PVC is flame retardant and can resist oil, sunlight, acid, weathering and abrasion, making this option useful for rugged environments and numerous applications. The 300 and 600-volt rated conductors can withstand 105 degrees Celcius.

- EPDM: Ethylene-propylene-diene elastomers or EPDM are available in 600 or 7,500 volts. They consist of EPDM insulation and stranded tinned copper, offering greater flexibility at low and high temperatures. The materials also provide better-cut-through resistance.

- Hypalon: The material is best known for its electrical properties and color stability. The Hypalon wire has tinned copper conductors and CPSE insulation, which makes it heat resistant. Hypalon is great for transformer lead, motor lead wire and appliance wire.

- Neoprene: Neoprene provides chemical resistance as it is made with neoprene electrical insulation. The material retains flexibility at high and low temperatures, which will not break down under pressure. The neoprene insulation material is also chemically stable in harsh environments.

- Silicone: Silicone jacketing offers excellent heat resistance and greater flexibility than other materials, so it is ideal for use in tight spaces.

- Rubber: Rubber displays excellent heat-resistant characteristics, along with flexibility, durability, and resistance to abrasion, tears, chemicals, water and oil.

When to Replace Hook-Up Wire

There are a few signs your hook-up wire is ready for replacement:

- Your home is more than 30 years old: If your home is over 30 years old, any outdated wires can pose electrical hazards.

- Your circuit breaker trips frequently: If you find yourself constantly tripping your circuit breaker, there’s likely too much demand on the electrical system, meaning it’s time for a replacement.

- You have frayed wires: Over time, wires can fray due to age, heat or corrosion. You should inspect and replace any frayed wires or stained and charred electrical outlets to reduce the risk of fire hazards.

- Your lights frequently flicker or dim: Flickering or dimming lights when using appliances might mean the electrical wiring is struggling to supply power.

Certain environmental and operational conditions can also influence when you should replace your hook-up wire. Exposure to heat, humidity and fluids causes wire materials to break down more quickly, while jacket and insulator materials can increase your hook-up wire’s longevity. Wires with PVC jackets, for instance, can last for many years.

Factors to Consider When Purchasing New Hook-Up Wire

Some factors to consider when buying hook-up wire for your application include:

Conductors

Copper has great thermal conductivity and resists corrosion, so you often find hook-up wires with copper conductors. Smaller diameter wires will have higher gauges, while wires with thicker diameters will carry more current with less resistance. Stranded conductors are more malleable, making them a better choice over solid conductors.

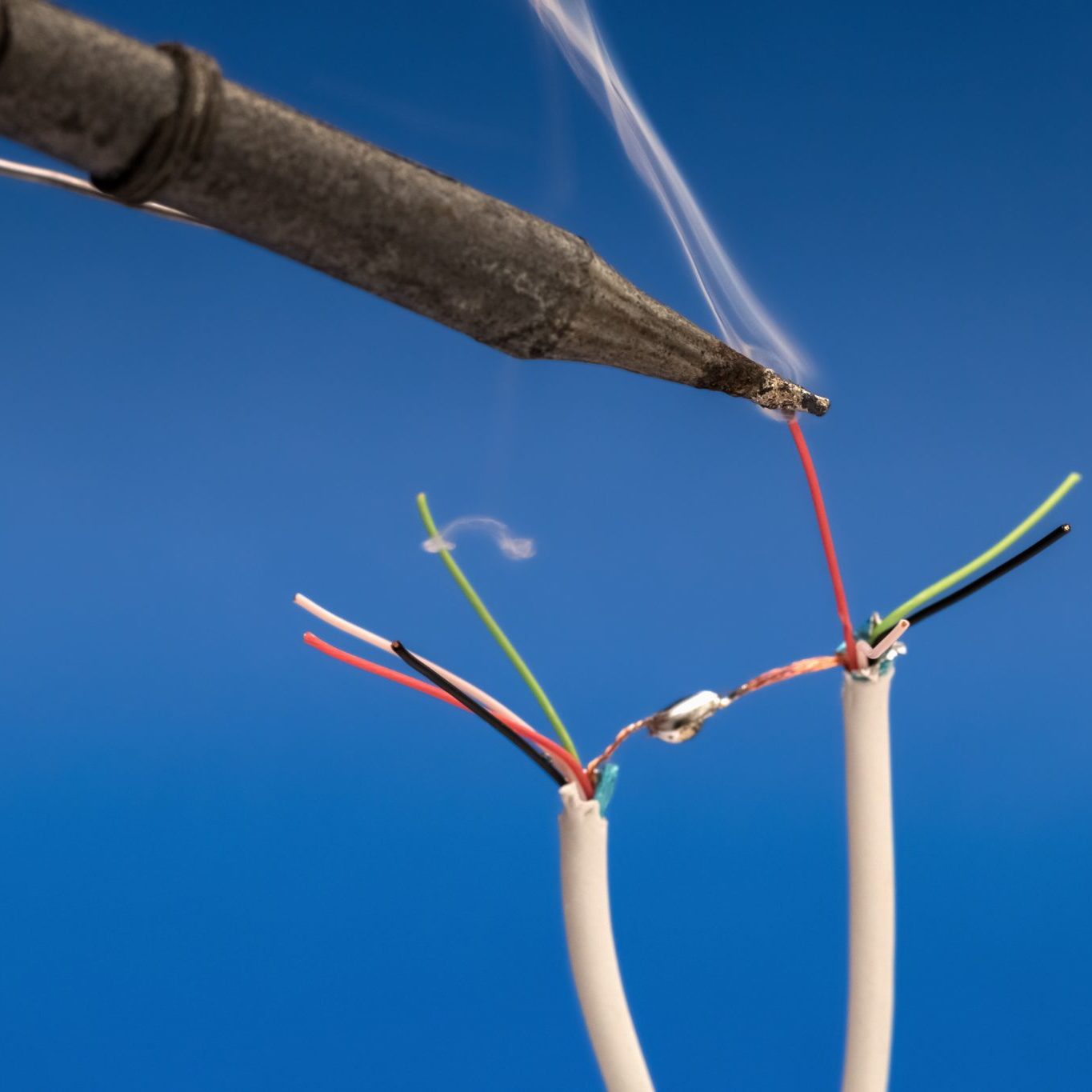

Materials

Ensuring you have the right jacket material for your application is important. For example, PVC wire without a nylon coating won’t resist water or moisture of any kind, so it won’t work for outdoor applications. For wire harness and assembly manufacturing, a tin coating makes it much easier to solder to bare copper.

Insulation Ratings

Insulation is crucial, as it protects your wire from damage and environmental hazards. You’ll want an insulation rating and material that matches your specific application. Perfluoroalkoxy (PFA) has low dissipation, making it incredibly electrically efficient. Polytetrafluoroethylene (PTFE) has a high-temperature rating and is resistant to water, oil, heat and chemicals.

Electrical wire insulation is color-coded depending on the gauge and voltage rating. For instance, white denotes 14-guage wires rated for 15 amps of voltage, while black insulation signifies six- to eight-guage wires for 40 to 60 amps.

Voltage

Your hook-up wire’s rated voltage will impact insulation thickness and other design features. Hook-up wires are best for low-voltage operations. In most cases, the voltage you choose will depend on what your equipment requires and the specific environmental conditions and temperatures your hook-up wire will be exposed to.

Sizing

The size of your hook-up wire often correlates with voltage ratings. Types UL1007 and UL1015, for instance, are very similar, except the UL1015 has a thicker jacket and supports twice the voltage at 600 volts. Usually, the UL1007 version only comes in 16 AWG through 26 AWG and the UL1015 comes in 16 AWG through 10 AWG. These smaller sizes usually indicate lower voltage capabilities.

Strands

Hook-up wire is typically manufactured with solid or thinly woven copper strands. Thin copper strands lend extra flexibility, making them great for applications that require bending. Meanwhile, solid-strand copper is stiff so that it can be molded into the necessary position and remain there.

Types of Hook-Up Wire We Offer

Now that you understand the different wires, you might wonder where to buy hook-up wires. WesBell Electronics offers an extensive selection of polyvinyl chloride. Some of the hook-up wires you can choose are for your individual needs include:

Kynar Wire

Kynar wire is a small but strong hook-up wire widely preferred for modifying or repairing home electrical devices. This wire type is known for its high conductivity, which accommodates a high level of voltage while promoting an uninterrupted power flow. It also has a flexible construction that makes it easy to solder or strip.

We offer Kynar wire in 26, 28 and 30 AWG sizes and 10 color options.

Type E

Type E wire is a hook-up wire comprising polytetrafluoroethylene (PTFE) insulation, which accounts for its high durability and damage resistance. This cable has a flexible structure and silver-plated copper strands with a PTFE jacket rated for 200 degrees Celsius. Type E wire supports 600 volts and is available in AWG sizes 14-26. It is most commonly used for indoor and outdoor applications that require high-temperature hook-up wire ratings.

Type EE

Type EE wire is a robust hook-up wire suited for high-capacity wiring applications in tough environments, such as:

- Military wiring

- Medical electronics

- Internal appliances

- Power supply lead wires

It features a strong PTFE insulation called Teflon, which resists chemicals and temperatures up to 200 degrees Celsius. We offer our Type EE wire in 1,000-volt capacities in AWG sizes 14, 16, 18, 20, 22 and 24.

Type ET

Our Type ET wire uses Teflon PTFE insulation to achieve high chemical and temperature resistance, including ratings from -60 to 200 degrees Celsius. This high-temperature hook-up wire is useful in indoor and outdoor applications, such as:

- Medical electronics

- Appliance wiring

- Power supply lead wire

- Military-grade harnesses

We offer this 250-volt wire in 20-32 AWG with numerous color options and bulk pricing discounts.

UL1007

UL1007 is among the most basic hook-up wire products, making it an excellent choice for general-purpose use. Popular for indoor appliance wiring and electronics manufacturing applications, UL hook-up wire comprises PVC insulation and tinned copper strands, giving this wire durability, flexibility and resistance to fire, water, chemicals and ultraviolet (UV) radiation. It is also rated for 300 volts and temperatures between -20 degrees and 105 degrees Celsius.

UL1015

UL1015 boasts excellent chemical and heat resistance, making it useful in indoor appliance and general electronics work. This hook-up wire is similar to its UL1007 counterpart, albeit with a higher voltage capacity of 600 volts. Like UL1007, this wire is rated for 105 degrees Celsius with a PVC coating for chemical and abrasion resistance.

You can purchase our UL1015 wire in AWG sizes 10-24, as well as many versatile color choices. We also offer spiral striping options.

UL1028

Like other hook-up wires, UL1028 has a structure comprising a stranded tinned copper conductor and PVC insulation, affording it excellent chemical and abrasion resistance and a 105-degree Celsius temperature rating. Like other UL-style wires, this product is useful for electronic equipment and indoor wiring applications. Because its tinned copper strands are thicker than other wires, UL1028 has a rating of up to 600 volts.

We carry this flame-resistant wire in AWG 8 with spiral striping options for all of our color choices.

UL1283

UL1283 hook-up wire is a flexible, high-voltage wire that resists flames and abrasion. It is most widely used in applications like device manufacturing, wire machining, thermoplastic equipment wiring and appliance wiring due to its 600-volt rating and temperature resistance of -40 to 105 degrees Celsius.

You can purchase our UL1283 wire in 4 and 6 AWG with 133 strands of tinned copper and various color-coding options.

Quality Wiring for Your Projects

Working on a project is exciting, but wiring might get in the way of the mission. Understanding hook-up wire will help you decide the correct wiring for the specific project.

Multiple hook-up wire manufacturers are on the market, but are they all trustworthy? At WesBell Electronics, we work with various manufacturers to ensure you get high-quality products. Contact us today to discover how we can help with your wiring needs.