Oct 12, 2020

UL1007 vs UL1015

For some projects, you need to decide which wires work best for your specific application. Knowing the difference between UL1007 vs. UL1015 and the individual features they have can make completing your project straightforward and clear. Take a look at the differences between UL1007 vs. UL1015 hook-up wires for your next wiring needs.

Which Projects Use UL1007 and UL1015 Wires?

UL1007 and UL1015 are both types of PVC hook-up wire used indoors in applications such as appliances and electronic devices. Both come in about 10 solid color options and an unlimited amount of striped color options. These features make both wires very convenient for contract assembly houses that manufacture wire harnesses and assemblies.

What is the Difference Between UL1007 and UL1015 Hook-Up Wire?

The two main differences between UL1015 wire vs. UL1007 are the outer diameter and the voltage rating. The small but mighty UL1007 wire rates account for 300 volts with an outer diameter of .016 inches. UL1015 wire rates contain 600 volts with an outer diameter of .030 inches. Other than those differences the two wires are nearly identical.

What Are the Similarities Between These Two Wires?

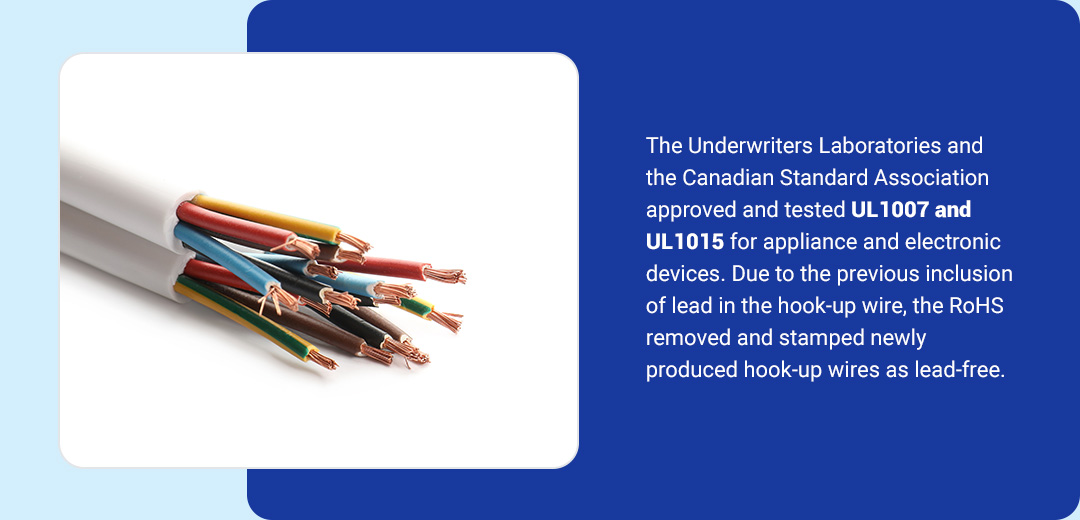

The Underwriters Laboratories and the Canadian Standard Association approved and tested UL1007 and UL1015 for appliance and electronic devices. Due to the previous inclusion of lead in the hook-up wire, the RoHS removed and stamped newly produced hook-up wires as lead-free.

There are more restricted materials on the list of being RoHS compliant, but the lead was the main reason for completing the project. Almost all wire and cable on the market is now RoHS compliant unless its manufacturing occurred over five years ago. You can ask for a compliant specification sheet proving that it is if you need it for your records.

Both types of 16 AWG PVC wire — UL1007 and UL1015 — contain 26 strands of 30 AWG tinned copper. The tin coating over the copper helps in the soldering process for contract assembly houses and personal users at home. Attempting to stick solder to bare copper is difficult but was proven easier with the additional tin coating over the copper. The tin adheres to the solder creating a much better and easier connection.

Feel free to call us with questions about bare copper, tinned copper, PVC wire or the UL, CSA and RoHS-compliant markings on the insulation. Everything from the copper strands to the markings on the insulation has a significant meaning in the application of that particular electrical wire. Make sure you consult your supplier or electrician to be sure the connection you’re about to make is correct. The worst that can happen is you’ll pick the brain of someone with direct experience in the industry to help you with your venture.

How Does UL1015 Wire Compare to UL1063 Wire?

The reliability and high power of UL1015 wires have some competition with the trusted UL1063 wires. While most electricians use UL1015 wires for the internal wiring of appliances, UL1063 wires are best for machinery heavier than your common household electronics.

The temperature ratings between these two wires also have a slight difference. Although UL1015 function best for smaller electronics and household appliances, they’re strong when withstanding internal temperatures. UL1015 wires have a maximum temperature rating of 105 degrees Celsius, with chemical and abrasion resistance. UL1063 wires have a temperature rating of 75 degrees Celsius in wet locations and 90 degrees Celsius in dry areas.

Both wires have rates of 600 volts, so they contain the same power for their project capabilities. The main difference is where these options are best suited. Talk with a trusted electrician or supplier to see if UL1063 vs. UL1015 is the best choice for you.

Choose UL1007 and UL1015 Wires From Wesbell Electronics

When your next project requires careful wiring, you can trust Wesbell Electronics to supply the wires you need. Our wide selection of hook-up wires, including UL1015 and UL1007, can support all kinds of internal wiring projects.

Buy UL1007 Wire here Buy UL1015 Wire here

If you’re still determining which hook-up wire you need for your next project, we can help make your decision easier. One of our experienced team members can assess your needs and suggest the proper wires and lengths to help you succeed with your task.

You can also enjoy our wide range of services to help you create even more wiring opportunities. From multiconductor portable cord preparation to cutting your cable to a desired length, we are here to make all your wiring needs easier so you can get back to your project in no time.

Contact us today with any questions.