Oct 12, 2020

PVC vs. Rubber EPDM Jackets and Insulation

Assume you need four wires to power your connection. Running each wire individually would be the old-fashioned way, but now, manufacturers surround all four wires with a polyvinyl chloride (PVC) or rubber jacket for protection and ease of installation. These two options, rubber and PVC, have different benefits, making them appropriate for varying situations. Knowing the difference between these two outer layers can help you better select the right cable for your work.

What Is EPDM Cable?

These cables use ethylene propylene diene monomer (EPDM), a type of rubber, as a jacket surrounding the wires. This cross-linked elastomer offers strong flexibility, durability and moisture resistance. It also works well across a wide range of temperatures, from around -55°C to 150°C, making it a good pick for high-temperature and high-voltage applications. It has better cut-through resistance than other rubber types and excellent flexibility.

You can find a rubber EPDM jacket on SOOW, welding cables and industrial power cables because these cables require more handling and outdoor use. They resist water, moisture, gas, solvents and oil while maintaining plenty of protection to the inner wires. They’re suitable for many rough outdoor or shop environments because they can withstand impacts, abrasion and more. EPDM cables are also resistant to the moisture and UV rays in these locations but are not always rated highly for chemical exposure.

Job sites with power tools must use SOOW cable, and industrial job sites often use Type W and Type G-GC cables. Cables such as these are dragged across dirt, rocks, cement and much worse while getting run over by trucks and stepped on each and every day. So an advertisement for power cables like this would probably look something like the “Ford Tough” commercials. Rubber jackets are some of the most rugged and durable jackets you can get.

What Is PVC Cable?

PVC jackets and insulation deliver general-purpose characteristics. They offer moderate durability and good resistance to UV rays, chemicals, and fire. PVC materials are widely used and cost-effective. They’re also easy to modify with additives like lubricants and plasticizers, making them suitable for more specialized environments. However, that also means that PVC cables can vary widely, so you’ll need to look closely at individual cables to determine if they are right for your application.

A PVC jacket is cheaper than rubber because it doesn’t offer the same environmental or impact resistance the inner wires may need. Romex, for instance, is an indoor cable, but using an electrical cable with all the wires included is much easier than running them individually. So, is there a point to having an expensive rubber jacket on the cable? Definitely not. PVC cables are a good choice for many light-duty applications that won’t be exposed to much movement or environmental stress, but they’re certainly not the most durable.

Another disadvantage of PVC is that it is susceptible to UV light and can crack or become brittle when left in the sun for a long time. If used in outdoor cables, PVC needs additional jacketing or special additives. When using PVC cables, you’ll also want to consider the halogen-based gases and smoke that are released if it burns. While it usually takes quite a high temperature for ignition, it’s not often used for densely populated buildings.

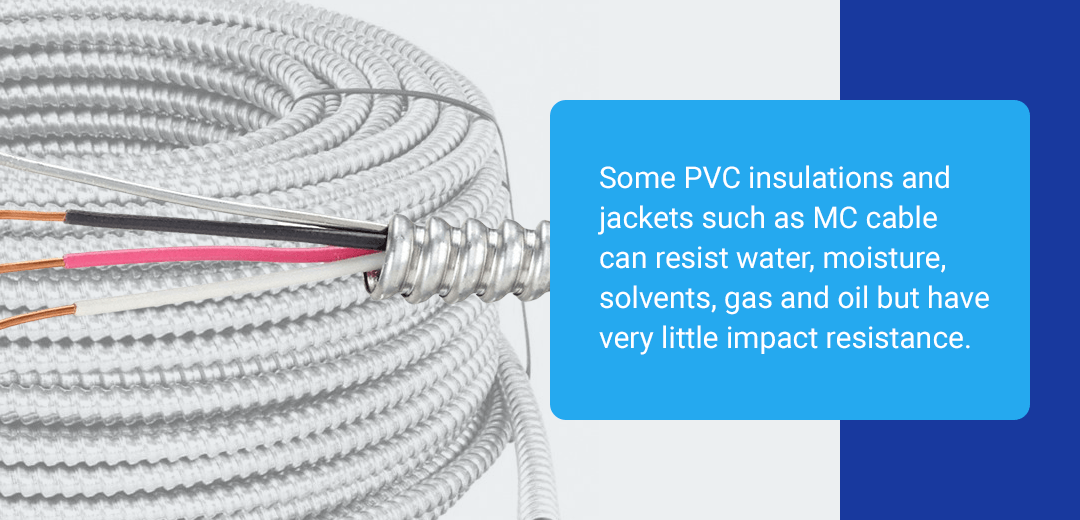

Some PVC insulations and jackets such as MC cable can resist water, moisture, solvents, gas and oil but have very little impact resistance.

What Type of Plastic Is Most Commonly Used in Cable Jackets?

PVC is the most common type of plastic used in cable jackets, due to its low cost and high versatility. While it won’t stand up to the tougher environments, it works well for light-duty applications. It’s appropriate for indoor and outdoor cables in a wide range of sizes and colors and can be flexible or fixed. With such a wide range of options, you’ll find PVC jackets in many different types of cables.

Which Rubber Is Used in Cable Sheathing?

Rubber can come in many forms, meaning many different materials, including EPDM, are used in cable jackets. Synthetic rubbers typically perform better than their natural counterparts and make up many of the rubber compounds in cables. They are either thermoset or vulcanized to avoid softening or melting upon exposure to heat. Additives can drastically change the performance of the materials.

Other Potential Rubbers In Cable Sheathing:

- Vulcanized India Rubber (VIR): VIR combines rubber with minerals and sulfur and undergo a vulcanization process. It has excellent mechanical strength and durability, but it reacts with copper, so tinned copper conductors are necessary.

- Polyethylene (PE): Polyethylene is another thermoplastic material like PVC. It’s more sensitive to moisture at high voltages and has lower dielectric losses than PVC. Its electrical properties make it a good choice for high-speed transmission cables that don’t need high flexibility.

- Cross-linked polyethylene (XLPE): By adjusting the chains in polyethylene molecules, XLPE can withstand higher temperatures. It also produces higher dielectric losses than PE but can support higher temperature ranges.

- Silicone: Silicone jackets have strong ultraviolet resistance, flexibility and durability. They’re commonly used in sensitive environments, like medical and aerospace applications.

- Natural rubber: Natural rubber has some strong insulating properties but it readily absorbs moisture, has a low temperature rating and is more prone to damage from handling or ultraviolet light. Pure rubber is not often used.

EPDM is one of the most rugged types of rubber, which is why it’s often used in tough environments. The type of rubber used often depends on the special requirements of your application and what the unique material has to offer.

PVC and EPDM Cables From WesBell Electronics

Manufacturers make electrical cables for virtually any scenario possible. There always seems to be a slight variation that warrants the manufacture of a new cable that consumers will purchase. PVC and EPDM cables come in many forms, and choosing the right one can be a little daunting.

At WesBell, wire and cable are our specialties. Be sure to discuss your application with us before buying. We can help you find the right cable and, if you already have something in mind, we can potentially find something better or cheaper that you may not know about. We can also help with preparation services, like cutting to length and stripping. Please reach out to us online or at 800-334-8400 to talk to a team member and find the right cable for your project.