Mar 26, 2018

UL1007 PVC Hook Up Wire Guide

UL1007 wire is an excellent general-purpose wire alongside UL1015 and Type E wires. Also known as PVC 300-volt lead wire, UL1007 uses polyvinyl chloride (PVC) insulation, offering chemical and heat resistance. It is dual-rated with UL1569 and features a conductor of tinned copper strands. This adds chemical, fire, water and ultraviolet resistance to the wire. UL1007 is durable, moderately flexible and has temperature ratings typically from -20 to 105°C. Keep reading our guide to learn more!

What Is UL1007 Wire?

UL1007 goes by many names. It is also known as PVC 300-volt lead wire, hook-up wire, appliance wire, electronic lead wire and more. Any of these terms can describe a single-conductor wire, so you’ll need to carefully consider the attributes that each type has to offer. For instance, UL1015 wire is rated for 600 volts but can also be described as all of the terms just mentioned. Look at the voltage and temperature rating to make sure the wire you’re looking at can handle your application’s environment.

UL1007 wire is dual-rated with UL1569, which are both approvals given by UL, LLC. Companies that manufacture UL1007/UL1569 wire test the insulation to the maximum amount. Having a third party that also tests and approves the wire provides the end user with confidence that it will perform the same at its maximum voltage and temperature rating. For this reason, UL-style numbers have become very popular in the hook-up wire industry.

We mentioned that UL1007 uses PVC insulation, but its other main component is tinned copper strands that make up the conductor. These design elements provide several beneficial characteristics, such as:

- Temperature ratings from -20 to 105℃.

- Fire, chemical, water and ultraviolet resistance.

- Durability and moderate flexibility.

These aspects make UL1007 wire a good candidate for things like electronics manufacturing and repair and indoor appliance wiring. If you need a wire that can withstand high heat or higher voltages, there are similar options in the UL1015 and Type E wires, which we’ll go over later. We sell all of these wires and carry the UL1007 in a range of different colors, including black, blue, gray, orange, green, brown, red, violet, white and yellow.

UL1007 Wire Specifications and Approvals

We make sure to only offer UL1007 wire that abides by several third-party standards. In addition to its UL approvals, UL1007 also meets several other specifications and approvals:

- CSA Group

- Restriction of Hazardous Substances (RoHS)

- Vertical wire flame test (VW-1)

3 Most Common Types of Hook-Up Wire

There are many different types of hook-up wire that you’ll likely come across when buying UL1007. Below are some of the most popular ones:

- UL1007 wire: UL1007 wire is rated for 300 volts and 105°C, with PVC insulation for indoor appliances, and electronics.

- UL1015 wire: UL1015 wire is rated for 600 volts, 105°C, with PVC insulation for indoor appliances, and electronics.

- Type E wire: Type E wire is rated for 600 volts, 200°C with polytetrafluoroethylene (PTFE) insulation for high-temperature indoor applications.

Each type of hook-up wire has slight differences to support various applications. Make sure you talk to your wire and cable supplier about your project, so you know what you’re buying and that it can last in the application.

For low-voltage and low-current applications, hook-up wire is usually the most appropriate connector choice. Low voltage refers to a voltage range below 1,000 volts and is common for enclosed electrical equipment typically seen in homes and offices. To name a few commonly encountered applications, you can find hook-up wires in computers, control panels, appliances, electronic meters and business machines like photocopiers and laminating machines.

| P/N | AWG Sizes | Stranding | O.D. | Weight Per 1000′ |

| UL1007-28-7 | 28 | 7 | 0.047 | 2 |

| UL1007-26-7 | 26 | 7 | 0.051 | 2 |

| UL1007-24-7 | 24 | 7 | 0.057 | 3 |

| UL1007-22-7 | 22 | 7 | 0.064 | 4 |

| UL1007-20-10 | 20 | 10 | 0.071 | 5 |

| UL1007-18-16 | 18 | 16 | 0.081 | 7 |

| UL1007-16-26 | 16 | 26 | 0.094 | 11 |

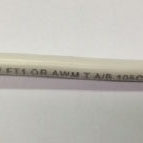

The name of this hook-up wire is derived from the tests and approvals used by Underwriter’s Laboratories and has become the industry standard name. UL uses the identification code “1007” to list all of the tests conducted in order to prove that the insulation over the copper strands does indeed meet the requirements. For example, UL1007 is supposed to meet 300 volts and 105°C, so UL will conduct those tests and stamp that number on the wire insulation for all to see.

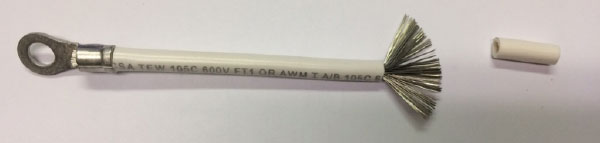

UL1007 Stranded Wire

The term stranded identifies multiple copper strands used to manufacture the wire. For example, 18 AWG wire is “18” because of the diameter, which is different from 16 AWG and 14 AWG because they are all different thicknesses. Well, it was discovered that the diameter is the key factor of conductivity, or in other words, 18 AWG wire can be comprised on a single solid strand or multiple smaller strands. The advantage of the smaller strands is the added flexibility. Some call it an advantage to have solid wire because they might be installing it, or snaking it, through tight areas where the solid wire becomes helpful.

UL1007 Solid Wire

We have a customer who makes Tiki Masks with our UL1007 solid wire. As you can see in the pictures below, the hair is made with different color wires that we cut and stripped for them. Many customers also use solid copper without insulation in art projects such as jewelry, bird feeders and stained glass. Whenever the wire is being formed into position, needs to hold its position or needs to be pushed through out-of-reach areas, solid wire is preferred over stranded.

UL1007 Wire Gauges (AWGs)

The most common size gauges for UL1007 are 16, 18, 20, 22, 24, 26 and 28. The largest size is 16 AWG (American Wire Gauge) and the smallest is 28 AWG. Each of these sizes are more popular in stranded but also come in solid upon request. Here is how the copper strands are wound together to meet the necessary diameter:

- UL1007-16 uses 26 strands of 30 AWG

- UL1007-18 uses 16 strands of 30 AWG

- UL1007-20 uses 10 strands of 30 AWG

- UL1007-22 uses 7 strands of 30 AWG

- UL1007-24 uses 7 strands of 32 AWG

- UL1007-26 uses 7 strands of 34 AWG

- UL1007-28 uses 7 strands of 36 AWG

The first four gauges are listed as 30 AWG strands but the amount of strands for each is different. As more strands are wound together the electrical current increases. Multiple strands act as a larger solid strand. These sizes can also get more flexible upon request. For example, UL1007-18 uses 16 strands of 30 AWG, but if 32 AWG is used instead, 41 strands are needed to reach the 18 AWG diameter. This will create a much more flexible wire for those who need it.

UL1007 Voltages and Temperatures

Unfortunately, UL1007 only comes in 300 volts and 105°C due to the name itself, UL1007. As mentioned in the first paragraph, UL1007 is a specific set of tests performed by Underwriter’s Laboratories to approve wire. Whenever people in the field see that something is approved for UL1007 they understand the approval process without having to research any further. In fact, many requirements sent from customers specify a UL style number and try to deviate away from it with added characteristics or attributes, such as asking for a UL1007 wire with a higher temperature. In this case it would be a different UL style completely. Higher temperatures and voltages are available, but they would just be listed under a different UL style.

UL1007 Wire Color Options

There are 10 specific color options almost always available somewhere online (Black, Brown, Blue, Gray, Green, Orange, Red, Violet, White and Yellow), along with two fairly standard colors (Pink and Tan) and the option of spiral striping. You can add a spiral stripe along the entire wire, usually for an additional charge, which will be made-to-order because of the many options available. Some wire harness assemblies need 50 wires with different colors and spiral striping becomes very popular for those types of jobs. Green with a Yellow stripe is a common color for grounding wires that need insulation.

UL1007 Dual Approval Ratings

You might see that UL1007 wire is also approved for UL1569 or also MTW or CSA approved. UL1569 is a very close approval and most wire manufacturers decided to make one wire with both approvals instead of stocking 10 colors of each variation. MTW is an acronym that stands for Machine Tool Wire and is mostly a descriptive phrase about how to use it. MTW is listed on many PVC wires with various temperatures and voltages. You might also see Appliance Wire written in the UL descriptions, which, again, is simply a descriptive phrase. CSA is the Canadian Standard Association that tests and approves wire similar to UL, but mostly in Canada. However, both UL and CSA are used throughout the US and Canada regularly, especially when shipping from the US to Canada or vice versa.

Stripping & Tin Dipping 300-Volt PVC Hook-Up Wire

These processes enhance the performance of your electrical wires. Lead wires often use rubber or thermoplastic insulation with lower heat resistance. Other materials like PVC, polyethylene (PE), neoprene, polypropylene, silicon rubber and propylene diene elastomers use polymers that can melt or disintegrate at high temperatures. To combat this weakness, you can strip and tin-dip the hook-up wires.

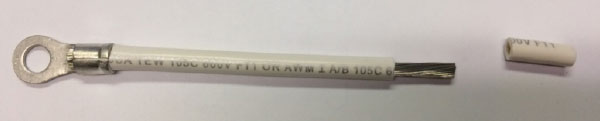

Stripping

Removing the insulation material from the ends of hook-up wires exposes the conductive material. Using wire strippers and the proper technique, you remove the insulation material without damaging the conductor. Use a gentle back-and-forth rocking motion, slowly pulling the sheathing away. Too much tugging or force can break the metal conductor underneath the insulation.

Tin Dipping

After stripping, the hook-up wires are tinned or tin-dipped to ensure the strands do not fray or oxidize, which can lead to corrosion. While you can strip wires on your own, tin dipping should be outsourced. This process involves melting tin at high temperatures and then dipping the ends of the hook-up wires in a molten tin bath of 450°F. Two layers form during this process — the interface, which is a mix of the tin and base material, and another layer of pure tin.

Order Your UL1007 Hook-Up Wire From WesBell Electronics

WesBell Electronics offers a range of high-quality UL1007 wires. We can strip and cut your hook-up wire to length, maintaining your order’s high-quality levels and safety grade. Reach out to our knowledgeable staff to help you find the right hook-up wires for your applications. Alternatively, you can call us at (800) 334-8400 for more information about our wire processing services.

If you need tin-dipping for your hook-up wire, be sure to reach out to us when placing your order. Our ISO 9001:2015 certified quality management system provides high-quality products for your project. We can also provide other services like stripping and cutting to length.