Nov 11, 2016

WesBell is Expanding Nationally with Services

WesBell Electronics was founded in 1988 by Kenneth Bell and Dean Westover, a perfect team of inside and outside sales. Dean traveled throughout New England developing strong relationships with customers while Kenneth remained at the office contributing to the relationships on the phone. Wire and cable distribution was the name of the game, buy large quantities of products from branded manufacturers and sell smaller quantities.

As the years went by many customers requested that we service the wire for them in some way, such as cutting it to length, adding a spiral stripe, twisting the wires together, and so on. Dean and Ken decided to reinvest some of the profits into new equipment that could service wire and cable products to add value to their business. While distribution remains 80% of our business in 2016, we’ve added tremendous value to our services department with equipment as extravagant as the size of a car that cut, strips, and terminates a wire in about one second.

Dean retired close to the year 2000 and I arrived, Ken’s son Chris, in 2003. I started to travel around New England in Dean’s place but soon came inside to build our company website. After building the website for 12 years, promoting it and getting over 20,000 new customers, we decided to hire a marketing firm to create additional functionality that allows our customers to not only purchase products on our website but also our services. With each segment of product, our website adds services, or value, to that particular product.

Electrical Wire for Contractors and Installers

In our electrical wire section is geared towards electrical contractors, electricians and installers who commit to projects that have an exact requirement of copper wire. THHN, NM-B, MC, and UF-B are all typical cables that are cut to length, installed and never seen again until something goes wrong. Therefore, we allow our customers to buy the exact amount of wire they need for each job without the added cutting costs or lead time. We also ship orders for free when they total $250 because heavy shipments can be difficult to set.

Flexible Portable Extension Cord in Construction

Portable cord products are used in shops, garages, warehouses and construction sites on a continuous basis, which means they need to be handled daily and very flexible. Welding cable, extension cords, DLO cable and high voltage flexible cables can be serviced on our website as well. Most often, we service the multi-conductor cables by removing some of the outer jacket and stripping the conductor insulation to exact requirements. Single conductor portable cord products can be cut to length, stripped and you can also add lugs to each end! We only use the finest branded Bundy® lugs for added quality in the field.

Flexible Hook Up Wire for Electronic Devices

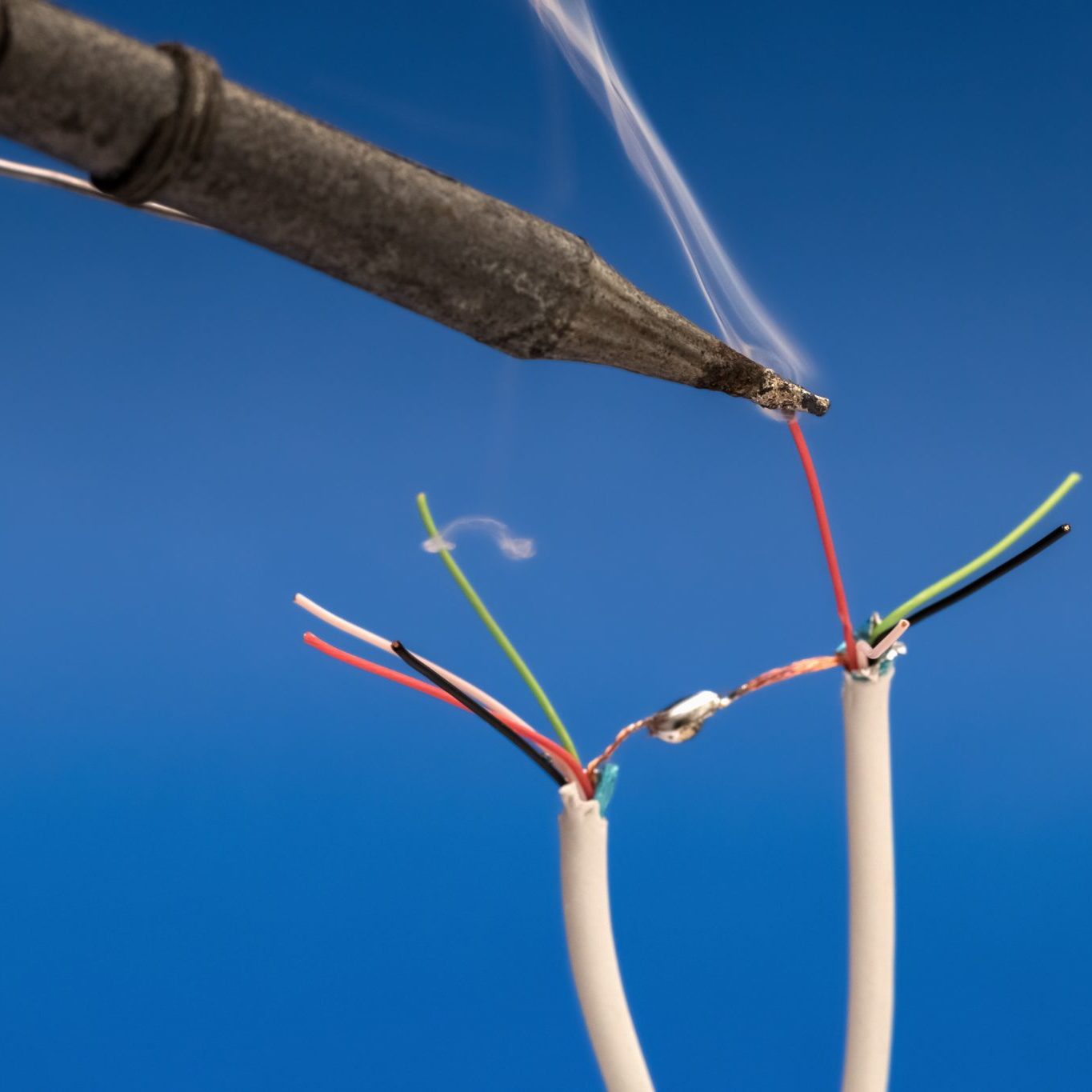

Most services are offered to our hook up wire section where customers can go through the process of buying 100’, adding a spiral stripe, twisting it with another color, cutting it to length, stripping the insulation off each end, and dipping the tinned copper strands into solder so that they hold their form without fraying during transit. It’s easy to buy 100’ of wire without services, and it’s easy to buy all of the services. The product total and services total will be separated at the bottom of the page, and it will increase as you add each service, so that you can see the cost of each.

Cables for Electronic Devices and Appliances

These are cables with multiple hook up wires, bundled together with the added protection of an outer jacket. They also come with a shield when EMI is a concern. These cables can be cut to length, the jacket can be removed to specification on both ends, the insulation can be stripped, and you can dip each conductor into solder to avoid fraying during transit.

Value Added Services for Wire and Cable

We also have services that aren’t on our website, such as manufacturing wire harnesses, cable assemblies, and additional soldering capabilities. We don’t engineer the products to work electronically, however, we can make any requirement you have as long as you send us the specifications to adhere to. We are ISO 9001:2015 and ISO 13485:2016 certified. We work to continuously improve our procedures and processes, manage risk opportunities and prevent errors from reoccurring.