Mar 26, 2018

Cutting, Crimping, Tinning and Poking UL1007 28 AWG Wire Harnesses

Table of Contents

- UL1007 28 AWB Wire Harness Cutting, Tinning and Poking Intro

- Cutting 28 AWG Wire to Length

- Tin Dipping 28 AWG Copper Strands on the First Side

- Foot Pedal Press Crimping 28 AWG UL1007 Wire

- Poking 28 AWG Wires into Hirose Housing

- Final Inspection on the UL1007 28 AWG Wire Harness

……………………………………………………………………

This article is going to show how to use UL1007 hook up wire to create a 28 AWG wire harness that’s press crimped and inserted into plastic housing. Underwriter’s Laboratories (UL) is a third party that tests and approves wire and cable products, then stamps their approval number onto the wire, and in this case, the end user has requested UL1007 approved wire. The basic attributes for the 1007 designation are 300-volt capacity and 105°C temperature rating. Typically, the contract manufacturer that makes the wire harness will also send a first article for the customer to inspect and approve before larger quantities are produced. This process is a part of ISO 9001:2015 risk mitigation rather than reacting to problems after they occur.

Cutting 28 AWG Wire to Length

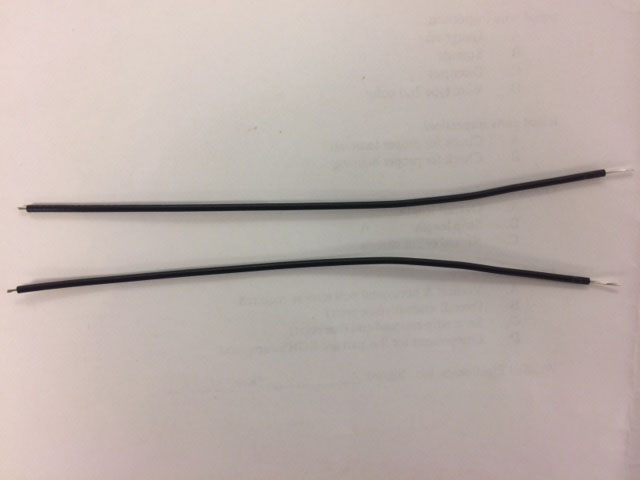

First, the wire will be cut on a wire cutting machine while simultaneously stripping the insulation from each end of the wire. Most wire harness tolerances are within 1/16 of an inch for the overall length, strip lengths and all other measurements listed on the specification sheet provided by the customer. Some customers require tighter tolerances than others so it’s important to understand the customer’s needs before producing the job. After cutting a few pieces the machine operator will measure and confirm that the lengths are accurate, then have a manager or supervisor sign a quality inspection report so that the operator can continue cutting the rest of the wire for the job.

Throughout the rest of the cutting process the machine operator will check an additional percentage of the wires for length accuracy and sign their initials after completing each subsequent quality check. Furthermore, additional quality inspections for cutting wire include looking for cut or scraped copper strands, torn insulation, possible damage to the insulation from the wheels, and possible corrosion on the copper strands. These additional checks have developed over the years completing similar types of jobs. It’s important for the copper strands to be fresh and undamaged while the insulation is also important to block electrical complications inside of the customer’s application.

Tin Dipping 28 AWG Copper Strands on the First Side

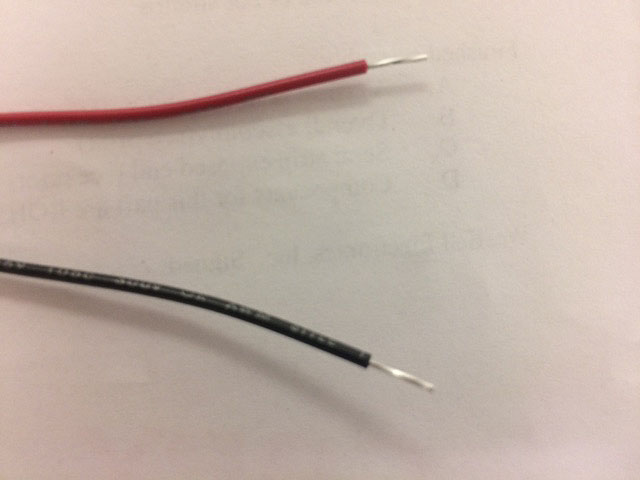

Next, the red and black wires will each be dipped into a pot full of tin so that all 7 of the copper strands meld together into one unit. It appears to be a straightforward process from the picture but there are plenty of thing to be aware of as an assembler assigned to complete this task. First, the mirror-like view of the tin is subject to spinning the handle around the top of the pot, otherwise the tin gets cloudy and thick. Secondly, the tin is typically set to a temperature of 800°F or higher for most jobs which can melt the PVC insulation if the wire is held too close for too long. Thirdly, the tin that adheres to the copper strands can be clumpy or left in a drip-like form if held too close for too long. Finally, the assemblers need to be careful that, before dipping, all the copper strands are wound together nicely because a run-away strand will be quite noticeable after being dipped that way.

Like the quality inspection completed for cutting the wire on the machine, the assemblers also complete quality checks and sign their initials to a quality inspection report (QIR) as they process. The potential problems listed above are important variations for the assemblers to look for as the process, to be sure that the customer receives a quality product consistently. Lastly for the tin dipping wire stage, it’s important for the contract manufacturer to understand the difference between 99.9% Lead free tin compared to 60/40% Lead Tin. RoHS, REACH and Conflict Minerals Reporting is very popular in the wire and cable industry in 2018 and most Original Equipment Manufacturers (OEMs) demand compliance from their vendors in these standards. Rarely, customers will request 60/40% Lead Tin, however it’s important to have the standard tin pots filled with 99.9% Lead Free Tin otherwise.

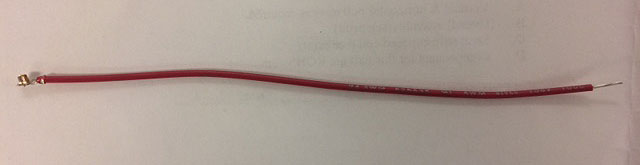

Foot Pedal Press Crimping 28 AWG UL1007 Wire

The foot pedal K-Press machine uses a reel of Hirose terminals that feeds into the K-Press and awaits the foot pedal activation to press crimp the terminal around the wire in two spots, the copper strands and the PVC insulation. As you can see in the video at the top of the page, a 28 AWG wire is small, but the terminals are even smaller which requires the operator to be careful when placing the wire, and their fingers, in exactly the right spot. A quality crimp will have the terminal wrapped around the copper strands and wrapped around the insulation. The operator will also consistently apply a manual pull test to be sure the terminal is tightly bound to the wire. Bad quality crimps are somewhat obvious to the naked eye since or quickly fail a manual pull test.

Poking 28 AWG Wires into Hirose Housing

Listen for the click! The terminals that are attached to the wire have a little flap on them so that they can easily slide into the house, click, and be unable to pull back out. If the flap on the terminal were to break off before inserting it into the house, then it would simply slide in and out without ever securing itself inside. The assemblers always listen for the click on the way in and then administer a pull test directly after. Typically, this is one of the easier tasks for the assemblers daily because there’s a sense of security to hear the click and know that the quality of the poke is based on a pass/fail basis.

Final Inspection on the UL1007 28 AWG Wire Harness

During the assembly process each of the assemblers complete in-process quality checks on a quality inspection report for each subsequent step along the way. The final inspection is completed by a manager or supervisor before shipping it to the customer. The manager will confirm that each item in the assembly matches the specification sheet provided by the customer, check all applicable lengths and measurements on the sheet and spot-check about 5% of the parts to be sure that the entire lot is of the upmost quality.

It’s also important to consider LEAN manufacturing initiatives such as one-piece-flow production lines when manufacturing wire harnesses. Batching building can create wasted labor from piling and boxing after each step, counting and recounting after completing each step and traveling around a production room with materials instead of sitting together in a line as a team. Completing each job as a team will allow them to quickly find bad pieces and help each other to complete each job in the quickest manner without compromising quality.