Feb 16, 2023

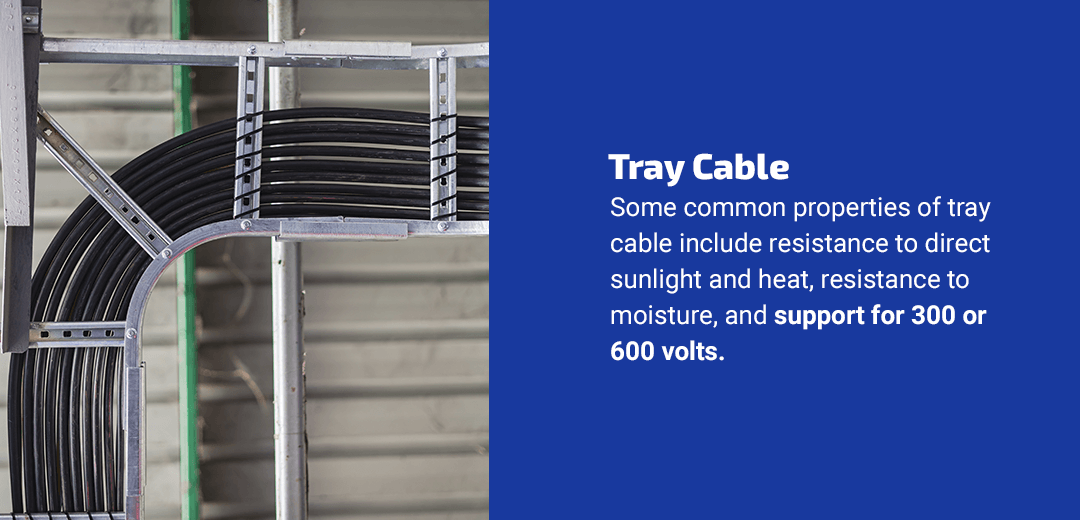

What is Tray Cable?

Tray cable is one of the most versatile types of cabling, and you’ll find it installed in cable trays or raceways in many locations. It is available in a wide range of configurations and helps electricians accomplish plenty of different tasks, making it an excellent all-purpose cable.

Since this cabling has such a wide-reaching job to do, it makes sense that there are a lot of different aspects to consider when buying your tray cable wire. Let’s take a closer look at this piece of material and see what all it can do.

What Is Tray Cable Wire?

You probably won’t be surprised to learn that tray cable wire comes in several different materials and designations that contribute to different capabilities. We’ll get into those more in the next section, but some of the qualities that you can find in tray cable wire include:

- Resistance to direct sunlight, heat, moisture and weathering.

- Effectiveness in direct burial applications.

- Indoor and outdoor operations.

- Support for 300 or 600 Volts.

Can You Put a Tray Cable in the Conduit?

For the most part, yes. You’ll have to look for the right approvals before placing tray cable wire in the conduit, but jacketing for in-conduit applications is fairly common.

Types of Tray Cable Wire

Tray cable is built to endure conditions like extreme heat, weathering, moisture and even sunlight. Therefore, the field of application for such wires and cables is expected to be extreme as well. Usually, these are used as cables for power and instrumentation. Some of the environments in which you might see tray cable include industrial plants, commercial facilities and chemical plants.

What Is Power Limited Tray Cable?

Tray cable comes in all different shapes and sizes, starting with the 300-volt power limited tray (PLTC) cable, available in shielded and unshielded versions. The two- and three-conductor cables come in American Wire Gauge (AWG) sizes 22 through 12, with an option for an aluminum polyester foil shield. The multipair 300-volt tray cable comes in 22 AWG and 18 AWG with an overall shield or a shield over each pair, known as an individually shielded cable.

What Is Vinyl Nylon Tray Cable?

The 600-Volt tray cable starts with a two-conductor shielded or unshielded version in 18 AWG through 12 AWG. In these 600-volt cables, you’ll only find an option for an overall shield. The multiconductor 600-Volt Vinyl Nylon Tray Cable (VNTC) comes with as many as 37 conductors in 18 AWG and 16 AWG. The insulation uses thermoplastic, high-heat, nylon-coating (THHN) for each conductor and the jacket is manufactured with polyvinyl chloride (PVC).

What Other Types of Tray Cable Are There?

The following are some other common categories of tray cable:

- Power and control tray cables (Type TC): Type TC cables involve two or more insulated conductors within a non-metallic jacket. They typically support 600 Volts and are common in industrial environments.

- Instrumentation tray cables (Type ITC): These cables are similar to PLTC cables but they don’t have the stipulation of being used only in power limiting circuits. This cabling can be installed in control and instrumentation circuits at 150 volts or below and 5 amps or below. They have a 300-volt rating, with sizes between 22 and 12 AWG.

- Fire alarm cables: Fire alarm cables can be power-limited or non-power-limited and are designed to behave under extreme heat and fire conditions.

- Communication cable: Communication cables offer radio frequency (RF) shielding, making them useful in various communications environments like radio stations, recording studios and intercom systems.

- Optical fiber cable: Fiber optic wire carries much more data than other wires and offers protection from electromagnetic interference. These wires can be conductive or non-conductive.

- Wind turbine tray cables (WTTC): Another specialized type of tray cable, these WTTC cables can stand up to the conditions in wind turbines, such as extreme temperatures, oil, and flexing and vibrations.

These types have different specific applications or use. Each has a specific set of features that may be advantageous for particular applications.

Tray Cable Materials

The material used for the manufacture of tray cable is stiff copper wire that is generally used for underground applications. Stiff copper wire is usually non-elastic and non-expandable, which is part of why it’s easy to apply and install. Copper is the material of choice for many known underground applications, thus making this a versatile choice for facilitating power and signal transmission while keeping interference to a minimum. It’s also used for connection in wire ways, furrows, channels, trays, trenches, gutters, conduits and racks.

This type of wiring and cable can withstand both ventilated and non-ventilated conditions. It is perfect for raceways and ladder-type cable trays. It can be buried under the earth but is also applicable for uncovered and sheltered environments, be it wet, moist or even dry conditions with temperatures down to -40°C. Tray cable follows a certain set of design standards that contain specifications for conductors, primary insulation, conductor identification and bonding conductor:

- The conductor is made up of seven strands of Class B tinned or uncovered copper wire, all bound together in a concentric manner. As you increase the expected voltage, the diameter rises accordingly. At 300 volts, the conductor should have a dimension of 0.519 to 2.08 square millimeters, or #20-14 AWG. At 600 volts, the conductor should have a dimension of 0.823 to 33.08 square millimeters, or #18-2 AWG. Lastly, for 1,000 volts, the conductor should have a dimension of 2.08 to 33.08 square millimeters, #14-2 AWG.

- The primary insulation can be of two types. The first type is made of a PVC compound appropriate for Type TW75-40 insulation to -40°C, dry conditions up to 75°C and wet conditions up to 75°C. The second type is made of flame-retardant cross-linked polyethylene (FR XLPE) compound that is appropriate for Type RW90-40 insulation to -40°C, dry conditions up to 105°C) and wet conditions up to 90°C.

The cables may come with two, three, four or even five conductors. The two-, three- and four-conductor cables are color-coded, while the five-conductor cables use alphanumeric codes.

The materials in these cables meet bend test and cold impact examinations and pass tests for hazardous applications, sunlight resistance, flame effects and others. Tray cable proves to be very reliable for industrial applications thanks to the material characteristics.

Things to Consider When Buying Tray Cable

We’ve gone over a few different configuration options that can create a tray cable, such as 300 and 600 volts and shielded, unshielded and individually shielded options for different types of applications. Typically, you’ll want to figure out the minimum amount of approvals and “extras” that you need to meet the job requirements. Knowing these must-haves can help you find tray cable pricing that is the most effective and affordable for your work.

Consider the following aspects when determining your needs:

- Volts: First of all, the 300-volt PLTC cables are cheaper than 600-volt cables. Do you need all 600 volts for your application?

- Shielding: The next thing to consider is the cost of the shield. You can save a lot of money by getting the unshielded option if your application is approved for an unshielded tray cable. However, if you do need a shield, don’t try to cut corners. These attempts to save money will only hurt you in the long run. If you need an individually shielded tray cable, each pair will have its own shield and drain wire.

- Jacket: Different types of tray cables have an outer jacket that can be approved for use indoors, outdoors, in conduit and directly underground. These are mostly broken into two categories of direct burial and NOT direct burial. The PLTC cables and tray cables not suitable for underground use are usually approved for everything else (indoors, outdoors, and in conduit).

Those are the simple things to think about before calling to order your tray cable. By listing these criteria, your wire and cable salesperson should be able to fit you with the right type of tray cable for your application. Our representatives are well-versed in finding the right cable for the job and are always happy to help.

Tray Cable From WesBell

At WesBell Electronics, we also cut most of our tray cable to the exact length our customers need. If we have it in stock, we’ll cut it for you. We also offer an array of services, as well as free shipping on orders over $500, so make sure you buy everything at once to maximize your savings.

We deliver quality products for effective, approved cabling in a wide range of applications. And we do all of that without sacrificing affordable tray cable pricing.

We’re known for exceptional service and can help you identify the right wires and cables for the job, whether that’s a specific type of tray cable or something else entirely. Reach out to us today for assistance or more information, or take a look at our tray cable inventory for purchase.