Dec 21, 2020

Hooking Up A Welder With Welding Cable

When hooking up a welder with welding cable, you must first understand how the equipment works. This will help you avoid accidents and allow you to be able to produce better products.

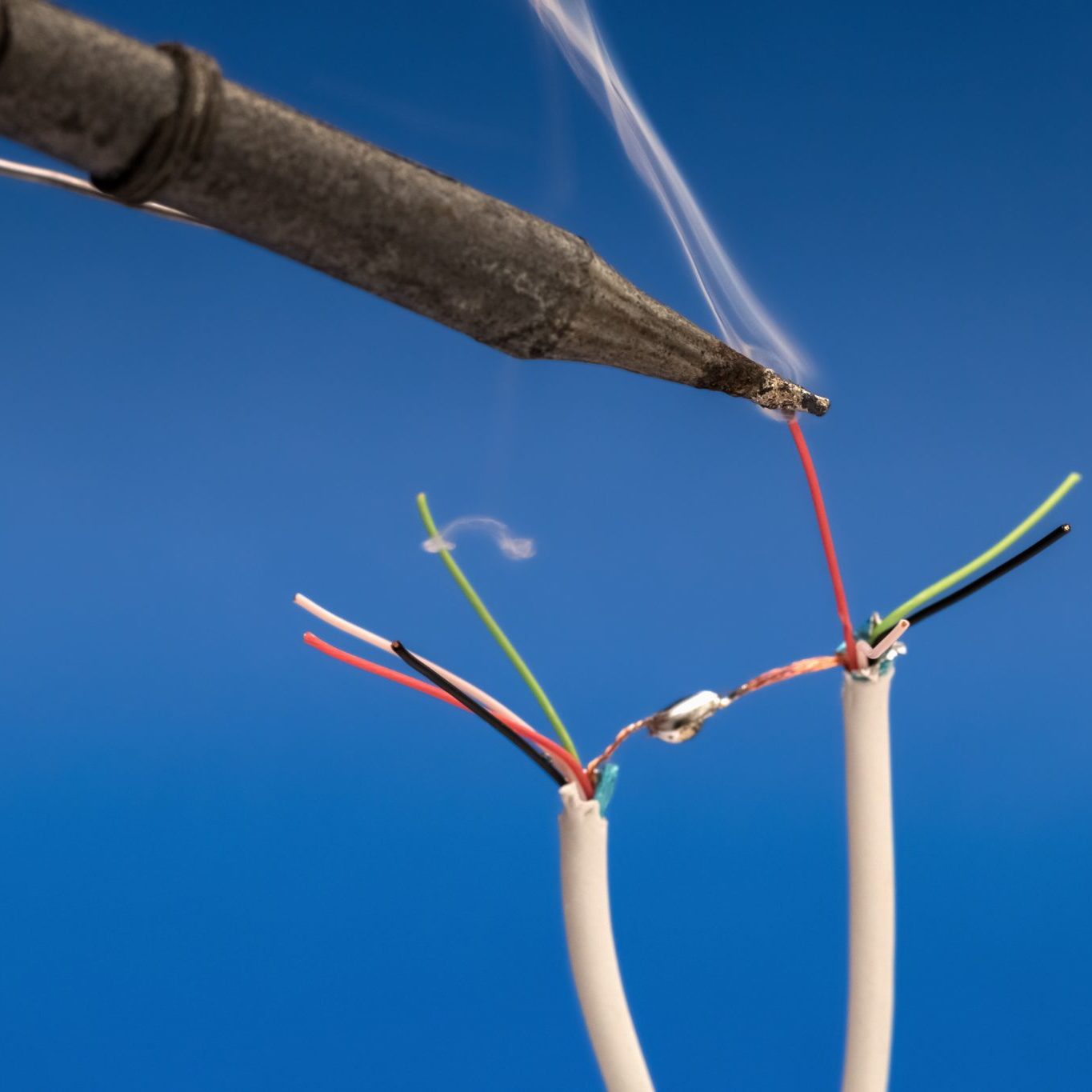

The welding cable is used to supply power to the secondary circuit of an electric welding generator. This circuit is used to control the electrode that releases the charge to perform the welding process. The welding cable is made of a flexible copper wire that’s surrounded with a protective covering in order to resist flame, oil, abrasion, and heat, among other things.

Two welding cables are required when using the electric welding equipment; one is used for connecting to the power supply, and the other one is used for the electrode. Most welding generators require the use of a secondary power source during the operation. The welding cable doesn’t produce any power for the welding generator. However, it is still needed to make the electrode function.

If you’re hooking up a welder with a welding cable, make sure that both are entirely connected as this may lead to risky malfunctions or worse, a very dangerous electrical accident. You can purchase a welding cable with the measures of length and diameter. It is sold in different segments as follows: Per foot, 25-foot, 50-foot, and 100-foot. The cable comes in 2 different colors (black and red) and 8 different gauges, so you may choose whatever you prefer.

The welding generator is very powerful equipment. Unless you know how to use the welder, it may be better if you ask a professional welder to do your welding project instead of trying to do it on your own as this can pose a danger to your life. However, the welding process is not that hard to perform once you get used to it. You can try starting on small projects or practice on scrap metals to get the feel of using the welding generator.

Here are some simple steps to follow to ensure a safe welding time

1. The first thing to do is to check all the welding cables for any damage. Replace the cable if necessary before you start working on any welding project. Watch out for nicks and frays on the welding cables as this can cause serious electrical hazards.

2. There’s an appropriate power source that corresponds to different types of welders. Plug the welder’s power source to the electrical outlet that matches your welder. The electric charge of the welding power source can provide a direct current (DC) or an alternating current (AC) with the use of either a negative or positive electrode. You can determine the current and polarity by the type of job you’re doing.

3. Hold the electrode lead with an insulated electrode holder. An electrical arc will form between the electrode and the base metal while you weld along with the metal.

4. Finish your work carefully. If you have started in hooking up a welder with welding cable correctly, then you need not be afraid of any danger.

Contact WesBell Electronics For Electrical Wire & Cable

Whether you need help with hooking up a welder with welding cable or looking for additional products for your next electrical project, WesBell can help! Reach out to our team today