Aug 20, 2024

5 Things to Check Before Buying the Right Wire (Solar Projects)

When planning an off-grid solar power project, one of the most crucial decisions is selecting the right type of wiring for your system. The quality and characteristics of the cables and connectors can significantly affect the overall efficiency, durability, and safety of your solar installation. Two primary choices for wiring in solar systems are copper welding cable and marine-grade cable, compared to aluminum cable and connectors. Each option comes with its advantages and disadvantages, but for off-grid solar applications, copper wiring generally offers superior performance.

In this analysis, we’ll compare the benefits of copper welding cable and marine-grade cable to aluminum cable and connectors in the context of an off-grid solar project.

0:00 – Intro to solar wire

0:48 – Choosing Copper vs aluminum

1:13 – Types of insulation to choose based on environment

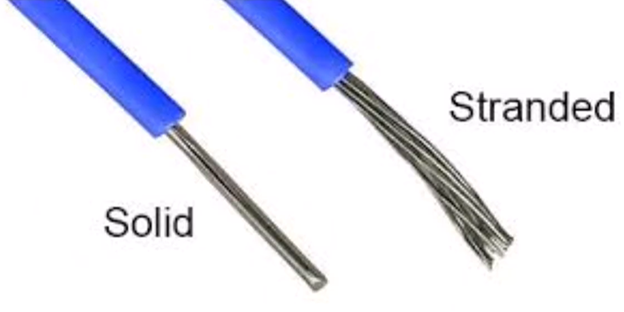

1:57 – Stranding options for flexibility

2:20 – Gauge size and length

3:00 – Calculators for AMPs

3:25 – Buy a bigger size than you need

- Conductivity

One of the most critical factors in solar wiring is conductivity, or the ability of the material to carry electric current.

Copper Welding Cable

- High Conductivity: Copper is one of the most conductive materials available, offering excellent electrical conductivity. This means that copper welding cable can efficiently transfer electricity from your solar panels to the charge controller, battery bank, and inverter with minimal loss.

- Low Resistance: Because of its superior conductivity, copper has lower electrical resistance than aluminum. This means less energy is lost as heat, making the system more efficient.

Marine-Grade Cable

- Tinned Copper Conductors: Marine-grade cable is often made of tinned copper, which combines the high conductivity of copper with additional corrosion resistance. Tinning the copper ensures that it remains conductive even in harsh environments, like those encountered in off-grid systems exposed to moisture or salt air.

- Optimal for Solar Applications: Marine-grade cable is especially advantageous for off-grid solar systems in humid or coastal areas because it maintains good conductivity over time.

Aluminum Cable

- Lower Conductivity: Aluminum has approximately 61% of the conductivity of copper. To carry the same amount of current as copper, aluminum cables must be larger in diameter, which may not be practical in tight spaces or installations with limited conduit sizes.

- Higher Resistance: Aluminum has higher electrical resistance, which leads to more power losses in the form of heat. In an off-grid solar project where every watt of power counts, this loss of efficiency can reduce the overall effectiveness of your solar array.

- Durability and Longevity

The lifespan and reliability of your wiring is crucial for long-term operation in off-grid solar systems. This is especially true for systems in remote locations where maintenance may be difficult.

Copper Welding Cable

- Durability: Copper is a durable material that can withstand physical stresses such as bending and twisting without breaking or becoming brittle. Copper welding cables are designed to be flexible and resistant to abrasion, which makes them ideal for solar installations where cables may be exposed to outdoor conditions.

- Long Lifespan: Copper cables tend to last longer than aluminum, especially when exposed to outdoor elements. Properly installed copper wiring can last for decades, even in challenging environments.

Marine-Grade Cable

- Corrosion Resistance: Marine-grade cables are designed to resist corrosion caused by salt, moisture, and other environmental factors. The tinning of copper strands helps prevent oxidation, which can degrade the performance of the cable over time. This makes marine-grade cable particularly valuable for off-grid solar installations in areas with high humidity or near bodies of water.

- Superior Insulation: Marine-grade cables often come with thicker, UV-resistant, and waterproof insulation, protecting the internal copper conductors from damage due to sunlight, water exposure, or temperature variations.

Aluminum Cable

- Susceptibility to Corrosion: One major drawback of aluminum cable is its vulnerability to corrosion, particularly in moist or coastal environments. When exposed to air, aluminum forms an oxide layer that increases electrical resistance and degrades performance over time.

- Brittleness and Breakage: Aluminum is more brittle than copper, and repeated bending or vibration can cause aluminum cables to crack or break. In a solar installation where cables might be exposed to wind, movement, or other environmental factors, this can lead to failures.

- Weight and Flexibility

Weight and flexibility are significant considerations when installing cables in off-grid solar projects. You may need to route cables through tight spaces or over long distances.

Copper Welding Cable

- Flexible: Copper welding cables are known for their flexibility. They are composed of finely stranded copper, which allows them to bend easily without breaking. This is particularly useful in off-grid solar systems where cables may need to be routed around corners or through conduits.

- Heavier Than Aluminum: While copper cables are heavier than aluminum, their flexibility often outweighs this drawback. The weight difference becomes an issue primarily in large-scale installations where a significant amount of wiring is required.

Marine-Grade Cable

- Highly Flexible: Like copper welding cables, marine-grade cables are also highly flexible. This makes them easier to work with, especially in complex or confined spaces where wiring needs to navigate through tight or irregular paths.

- Heavier Due to Insulation: Marine-grade cables tend to be heavier than standard copper cables due to their thick, robust insulation. While this adds to their durability, it can make installation slightly more challenging in certain circumstances.

Aluminum Cable

- Lighter Weight: One of the primary advantages of aluminum cable is its lower weight compared to copper. This can make aluminum more attractive for large-scale projects where reducing weight is critical, such as in mobile applications or projects requiring long cable runs.

- Stiffer and Less Flexible: Aluminum cables are typically stiffer and less flexible than copper. This can make installation more challenging, especially in situations where the cable needs to be bent or routed through complex paths.

- Installation Costs

The cost of materials and installation plays a significant role in deciding between copper and aluminum cables for solar projects.

Copper Welding Cable

- Higher Material Costs: Copper is more expensive than aluminum, which increases the upfront cost of using copper welding cable in an off-grid solar project. However, many consider this a worthwhile investment due to its superior conductivity, durability, and longevity.

- Lower Installation and Maintenance Costs: Although copper costs more initially, its ease of installation, flexibility, and long lifespan can lead to lower overall installation and maintenance costs. The reduced likelihood of failure or need for replacement makes copper more economical over the long term.

Marine-Grade Cable

- Higher Costs Due to Specialization: Marine-grade cables are generally more expensive than standard copper welding cables because of the tinning process and higher-grade insulation. However, these features provide additional protection, particularly in harsh environments, which can justify the extra cost in off-grid installations prone to corrosion or weather exposure.

- Reduced Long-Term Costs: Like copper welding cables, the durability and longevity of marine-grade cables can reduce the need for repairs or replacements, saving money in the long run.

Aluminum Cable

- Lower Material Costs: Aluminum cables are generally less expensive than copper, making them appealing for budget-conscious projects. However, the need for larger gauge cables to match copper’s conductivity increases the amount of material required.

- Higher Installation and Maintenance Costs: Aluminum is more difficult to work with, and additional precautions are necessary to prevent issues like corrosion and connection failures. This can result in higher installation costs, as well as more frequent maintenance and potential replacement down the line.

- Safety and Reliability

Safety is paramount in any electrical installation, particularly in off-grid solar projects where maintenance might not be immediately accessible.

Copper Welding Cable

- Reliable Performance: Copper’s excellent conductivity and resistance to corrosion make it a reliable choice for solar systems. Copper connections are also less prone to loosening over time compared to aluminum, reducing the risk of electrical fires or shorts.

- Higher Melting Point: Copper has a higher melting point than aluminum, which means it is less likely to overheat under high current loads, further enhancing safety.

Marine-Grade Cable

- Safe in Harsh Conditions: Marine-grade cable offers superior safety in harsh or unpredictable environments. Its resistance to corrosion, UV rays, and water ingress makes it a safer choice for outdoor or remote installations, particularly where maintenance might be difficult.

- Prevention of Oxidation: The tinned copper conductors in marine-grade cables prevent oxidation at connection points, which helps maintain strong, safe electrical connections over time.

Aluminum Cable

- Risk of Connection Failures: Aluminum cables are more prone to loosening at connection points, especially when exposed to temperature fluctuations. Loose connections can lead to arcing, overheating, and potential fire hazards.

- Corrosion Issues: Aluminum’s susceptibility to corrosion increases the risk of failure in moist environments. This can compromise the safety of an off-grid solar system, particularly if regular inspections are not feasible.

Conclusion

When considering wiring options for an off-grid solar project, copper welding cable and marine-grade cable offer significant advantages over aluminum cable and connectors, particularly in terms of conductivity, durability, safety, and long-term reliability.

- Copper welding cable is ideal for its flexibility, high conductivity, and ease of installation. It excels in environments where the wiring may be subject to movement or physical stress.

- Marine-grade cable provides enhanced protection against environmental hazards like corrosion, moisture, and UV exposure, making it especially valuable in coastal or humid off-grid solar projects.

- Aluminum cable, while cheaper and lighter, presents greater risks due to its lower conductivity, susceptibility to corrosion, and connection issues, which can compromise the long-term safety and efficiency of the system.

Ultimately, the higher upfront cost of copper and marine-grade cables is offset by their superior performance, making them the better choice for most off-grid solar projects, particularly those in harsh or remote environments where reliability and safety are paramount.