May 5, 2021

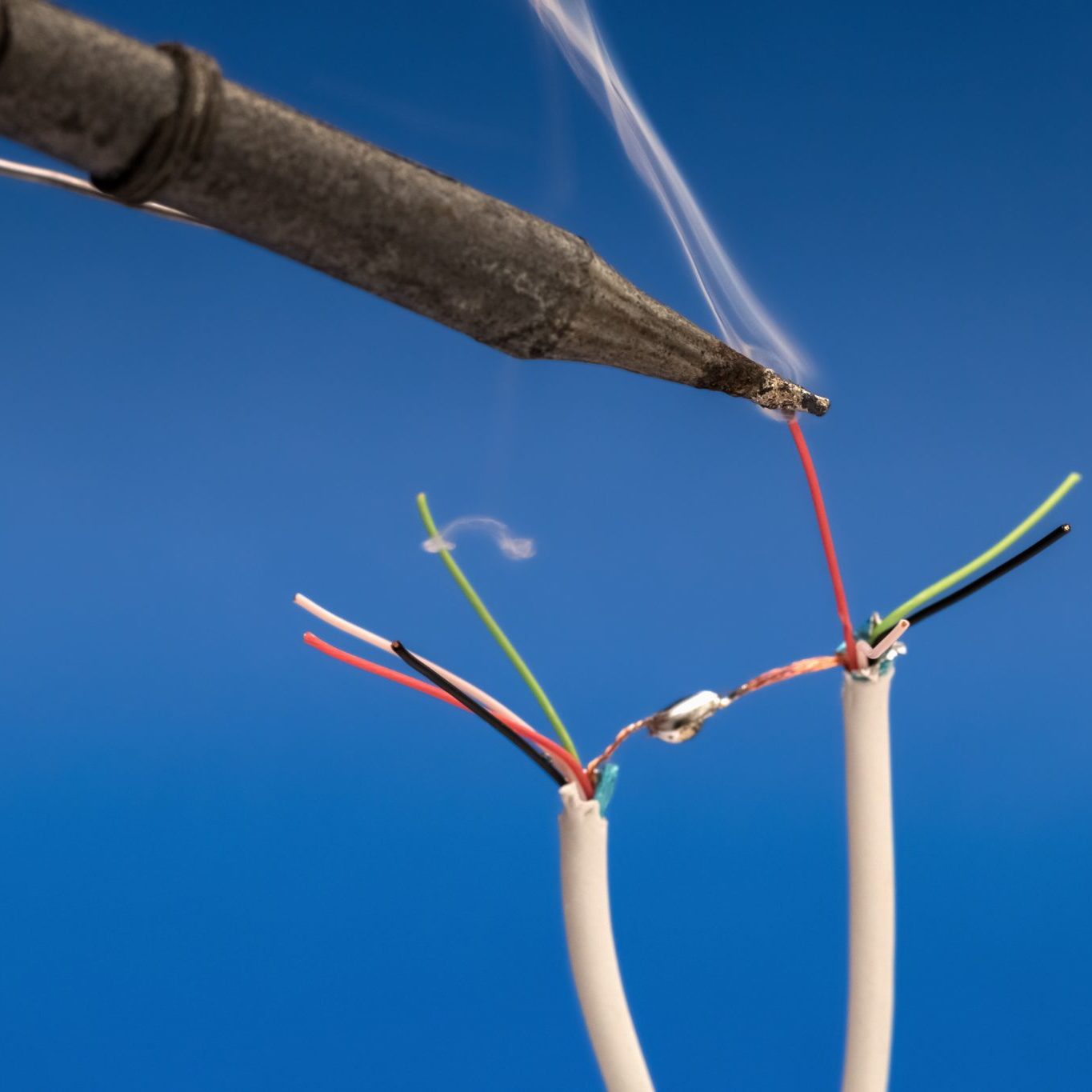

Why Are There Different Types of 18 Gauge Lead Wire?

Different types of 18 awg lead wire are engineered each time there is a new application because there are different circumstances in each situation. The common denominator with each lead wire is the amount of electricity that can travel through a copper wire as thick as 18 awg. The differences are voltage, environmental temperature and possibly weather or moisture that could damage or puncture the insulation.

An 18 awg solid bare copper wire is the most basic because it doesn’t even have insulation at all. It’s a solid piece of copper used as a ground wire for most electrical applications.

The next step up would be the UL1007 wire and UL1015 wire which are nearly identical aside from the voltage difference. UL 1007 has slightly thinner insulation because it’s approved for 300 volts, which makes it cost less as well. UL 1015 is thicker with a 600 volt rating and both come with a temperature rating of 105°C.

Teflon is a high-temperature wire called Type E or M16878/4 wire. It’s manufactured with PTFE insulation and silver-plated copper strands rating it as high as 200°C. It’s much more expensive than PVC wire because it has copper, silver and PTFE compound which is becoming difficult to get your hands on.

TFFN 18 awg wire is rated at 90°C in dry locations and 75°C in wet locations. It has PVC insulation with a nylon coating and it is less flexible than conventional PVC wire so it’s easier to use in electrical applications. Pushing a flexible wire through conduit would be very difficult because it would keep bunching up.

Those are just a few types of 18 awg wire available through WesBell Electronics online or over the phone. We offer free shipping on orders over $500 and offer small spool sizes so that you can limit your waste on each job. Please call or contact us if you have any questions about our products or our blog posts!