Aug 30, 2024

EcoCable and EcoFlex Recyclable Control Cables by Alpha Wire (EcoWire & EcoWire Plus mentioned)

In an era where sustainability is becoming a priority, the demand for environmentally friendly materials has surged across various industries. The electrical and electronics industry, in particular, has witnessed a shift towards eco-friendly wiring solutions that reduce environmental impact without compromising on performance. Alpha Wire, a leading manufacturer of wire, cable, and tubing products, has responded to this demand by developing a range of sustainable products, including Alpha Ecowire, Ecowire Plus, EcoGen Ecocables, and EcoFlex. These products are engineered to meet the rigorous demands of modern applications while minimizing their ecological footprint.

0:34 – Alpha EcoWire

0:40 – EcoWire Plus

1:08 – mPPE jacket material

1:20 – List of features

2:56 – Alpha Catalog information

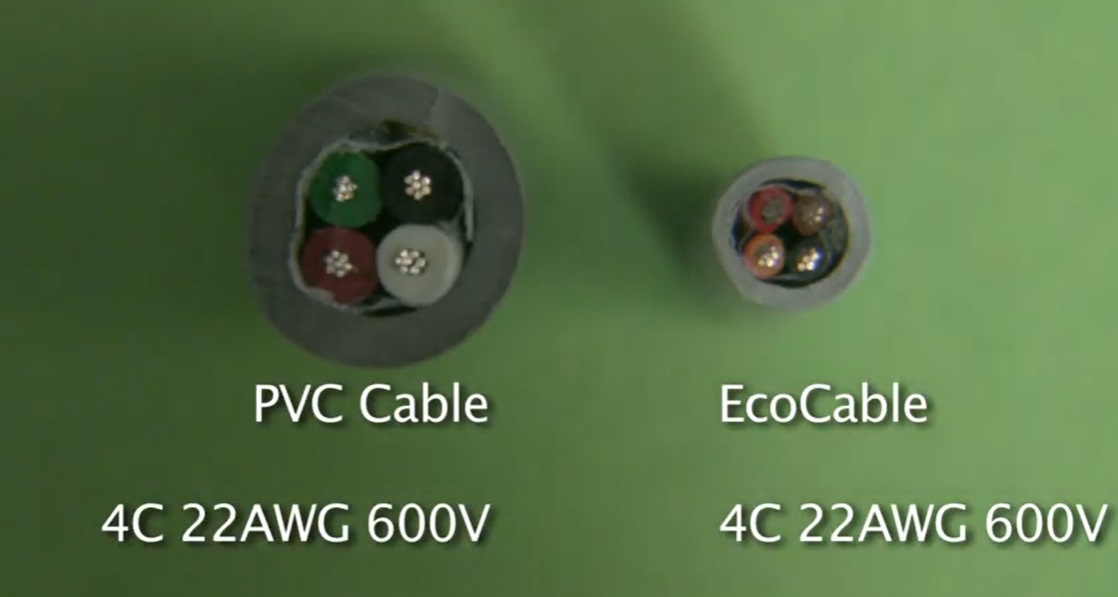

3:25 – EcoCable VS standard PVC cable

4:03 – EcoFlex VS PVC Flex cables

This detailed discussion will cover the benefits and construction of these innovative products, highlighting how they contribute to sustainability and performance in various applications.

1. Alpha Ecowire

Benefits:

- Environmental Sustainability:

- Alpha Ecowire is an eco-friendly alternative to traditional PVC wire. PVC (polyvinyl chloride) has been a standard material in the wire and cable industry due to its durability and cost-effectiveness. However, PVC contains halogens and other harmful substances that can have significant environmental impacts, especially when disposed of or incinerated. Alpha Ecowire eliminates these concerns by using modified polyphenylene ether (mPPE) as its insulation material. This material is halogen-free and RoHS-compliant, significantly reducing the environmental impact.

- Reduced Weight and Size:

- One of the key benefits of Alpha Ecowire is its lightweight and compact design. Compared to traditional PVC wire, Ecowire can be up to 45% smaller and 40% lighter. This reduction in size and weight can lead to improved efficiency in applications where space and weight are critical factors, such as in aerospace, automotive, and industrial automation.

- Enhanced Electrical Performance:

- Despite its smaller size, Alpha Ecowire offers superior electrical properties, including higher dielectric strength, which allows for thinner insulation without compromising safety or performance. This makes it suitable for high-density wiring applications where space is at a premium.

- Flexibility and Durability:

- Alpha Ecowire is highly flexible, making it easier to install in tight spaces or complex configurations. It also has excellent resistance to abrasion, chemicals, and fluids, ensuring long-term durability in demanding environments.

- Cost Efficiency:

- The material efficiency of mPPE insulation, combined with its lightweight construction, can lead to cost savings in transportation and installation. Additionally, the extended lifespan of the wire reduces the need for frequent replacements, further lowering total costs.

Construction:

Alpha Ecowire is constructed using a conductor, typically made of stranded or solid copper, surrounded by a modified polyphenylene ether (mPPE) insulation. The mPPE material is a thermoplastic with excellent insulating properties, allowing for a thinner insulation layer compared to traditional materials like PVC. This results in a smaller overall wire diameter without compromising electrical performance.

The insulation material is halogen-free, which means it does not emit toxic gases when exposed to high temperatures or flames. This makes Alpha Ecowire a safer choice in applications where fire safety is a concern.

2. Ecowire Plus

Benefits:

- Enhanced Environmental Performance:

- Ecowire Plus builds on the foundation of Alpha Ecowire, offering even greater environmental benefits. Like Ecowire, it is free of halogens and heavy metals, but it also meets stricter environmental regulations and standards. Ecowire Plus is designed to comply with the latest global environmental directives, including RoHS (Restriction of Hazardous Substances), REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals), and the Waste Electrical and Electronic Equipment Directive (WEEE).

- Superior Flexibility:

- One of the standout features of Ecowire Plus is its exceptional flexibility. It is designed for dynamic applications where constant movement and bending are required, such as in robotics, automation, and portable equipment. The wire’s flexibility reduces the risk of damage during installation and operation, leading to longer service life and fewer maintenance requirements.

- Improved Thermal Performance:

- Ecowire Plus offers superior thermal resistance, with the ability to withstand higher operating temperatures compared to standard wires. This makes it suitable for use in environments where extreme temperatures are a concern, such as in automotive under-hood applications or industrial machinery.

- Chemical and Fluid Resistance:

- The construction of Ecowire Plus includes materials that are highly resistant to chemicals, oils, and fluids commonly encountered in industrial and automotive environments. This resistance enhances the durability and reliability of the wire in harsh conditions.

Construction:

Ecowire Plus is constructed using a conductor made of high-quality copper, which is then insulated with a proprietary blend of materials designed to offer enhanced flexibility and environmental performance. The insulation material is halogen-free and provides excellent dielectric properties, thermal resistance, and chemical resistance.

The conductor may be stranded or solid, depending on the specific application requirements. The insulation is designed to be thinner than traditional materials, contributing to the wire’s compact size and reduced weight.

3. EcoGen Ecocables

Benefits:

- Comprehensive Eco-Friendly Solution:

- EcoGen Ecocables represent a broad range of environmentally friendly cables designed to replace traditional PVC cables across various applications. These cables are made from materials that are free of halogens, phthalates, and heavy metals, significantly reducing their environmental impact. They are also fully recyclable, further contributing to sustainability.

- Wide Range of Applications:

- The EcoGen product line includes cables for a variety of applications, including data transmission, power distribution, and signal control. This versatility makes EcoGen cables suitable for use in industries such as telecommunications, industrial automation, medical devices, and renewable energy.

- Enhanced Performance Characteristics:

- EcoGen cables are engineered to offer superior performance characteristics compared to traditional cables. They feature high dielectric strength, excellent thermal stability, and resistance to chemicals and fluids. This ensures reliable operation in demanding environments while maintaining environmental compliance.

- Space and Weight Savings:

- Like Ecowire and Ecowire Plus, EcoGen cables are designed to be smaller and lighter than traditional PVC cables. This allows for more efficient use of space and reduces the overall weight of wiring systems, which is particularly beneficial in applications like aerospace, automotive, and portable electronics.

- Cost Efficiency and Longevity:

- The advanced materials used in EcoGen cables contribute to their long-term durability, reducing the frequency of replacements and lowering the total cost of ownership. Additionally, the cables’ recyclability can lead to cost savings in waste management and disposal.

Construction:

EcoGen Ecocables are constructed using high-quality conductors, typically made of copper, surrounded by insulation and jacket materials that are free of halogens, phthalates, and heavy metals. The specific construction varies depending on the type of cable and its intended application.

For example, EcoGen data cables may feature twisted pair constructions with shielding for electromagnetic interference (EMI) protection, while power cables may have thicker insulation and additional protective layers to handle higher voltages and currents.

The insulation and jacket materials used in EcoGen cables are engineered to provide excellent electrical and mechanical properties while being environmentally friendly. These materials offer high dielectric strength, thermal stability, and resistance to chemicals and fluids, ensuring reliable performance in a wide range of conditions.

4. EcoFlex

Benefits:

- Maximum Flexibility:

- EcoFlex cables are designed to offer maximum flexibility, making them ideal for dynamic applications where the cables need to be bent, twisted, or moved frequently. This includes applications in robotics, automation, medical devices, and portable equipment. The flexibility of EcoFlex cables reduces the risk of damage from mechanical stress, leading to longer service life and fewer maintenance requirements.

- Environmental Responsibility:

- Like the other products in the EcoGen range, EcoFlex cables are made from environmentally friendly materials that are free of halogens, phthalates, and heavy metals. They are fully recyclable and comply with the latest environmental regulations, making them a sustainable choice for modern applications.

- Durability and Reliability:

- Despite their flexibility, EcoFlex cables are designed to be highly durable, with excellent resistance to abrasion, chemicals, and fluids. This makes them suitable for use in harsh environments where cables are exposed to mechanical stress and corrosive substances.

- Temperature Resistance:

- EcoFlex cables offer excellent thermal resistance, allowing them to operate in a wide range of temperatures. This makes them suitable for use in applications where temperature fluctuations are common, such as in industrial machinery or outdoor equipment.

- Cost Efficiency:

- The advanced materials and construction of EcoFlex cables contribute to their long-term durability and reliability, reducing the need for frequent replacements and lowering the total cost of ownership. Additionally, the lightweight and compact design of EcoFlex cables can lead to cost savings in transportation and installation.

Construction:

EcoFlex cables are constructed using a flexible conductor, typically made of stranded copper, surrounded by an insulation material that is both flexible and environmentally friendly. The insulation material is designed to provide excellent electrical properties while being thin and lightweight, contributing to the overall flexibility of the cable.

The jacket material used in EcoFlex cables is also designed for flexibility, with additional features such as abrasion resistance and chemical resistance to ensure long-term durability in demanding environments. The combination of flexible conductors and advanced insulation and jacket materials makes EcoFlex cables ideal for applications where movement and bending are frequent.

Conclusion

The development of Alpha Ecowire, Ecowire Plus, EcoGen Ecocables, and EcoFlex represents a significant advancement in the field of environmentally friendly wiring solutions. These products offer a range of benefits, including reduced environmental impact, improved performance, enhanced durability, and cost efficiency. By replacing traditional PVC wires and cables with these eco-friendly alternatives, industries can contribute to sustainability while maintaining the high standards of performance and reliability required in modern applications.

The construction of these products is carefully engineered to meet the demands of various industries, from industrial automation and automotive to telecommunications and medical devices. The use of advanced materials, such as modified polyphenylene ether (mPPE) and other proprietary blends, ensures that these cables provide superior electrical and mechanical properties while being safe for the environment.

In summary, the Alpha Wire eco-friendly product line provides a comprehensive solution for industries seeking to reduce their environmental footprint without compromising on quality or performance. As the demand for sustainable solutions continues to grow, these products are likely to play an increasingly important role in the future of wiring and cabling.