Jun 4, 2018

Cutting, Stripping and IDC Crimping UL1007 18 AWG Wires

Table of Contents

- Cutting, Stripping and IDC Crimping UL1007 18 AWG Hookup Wire

- UL1007 18 AWG Wire

- Cutting and Stripping UL1007 18 AWG Wire

- IDC Crimping UL1007 18 AWG Wire

- Final Quality Control Check

…………………………………………………

Cutting, stripping and IDC crimping a wire harness is a simple job to complete, and I’ll go through each step to describe exactly what’s happening. UL1007 18 AWG hookup wire arrives on a spool, gets cut and stripped on a wire processing machine and gets crimped through the insulation into a terminal-housing. Once the wires are cut and stripped on the machine they get crimped into the house but a quick conductivity test is important on IDC crimps and I’ll let you know why as I move through this harness.

UL1007 18 AWG Wire

Underwriter’s Laboratories (UL) tests and approves 1007 to 300 volts and 105°C, then approves that the manufacture can in fact produce hundreds of thousands or millions of feet at a time. Customers and end users see the UL1007 style printed on the insulation and know that it’s been tested and approved by not only the manufacturer but also the third-party approval source.

The American Wire Gauge (AWG) is the thickness of the copper or the overall thickness of multiple strands of copper. For instance, the outer diameter of UL1007 18 AWG wire is approximately 0.081” and the insulation thickness (set based on voltage and temperature ratings) is 0.016” on both sides. The copper underneath the insulation is 0.049” (or .081 – .016 – .016), whether it’s solid or stranded. It’s been determined that a solid strand of copper at 0.049” thick will conduct the same amount of electricity as 16 strands of copper wound together with an overall diameter of 0.049”.

This wire uses tinned copper strands rather than bare copper as well, so the strands, when exposed, could appear to be silver when they aren’t. To help with the soldering process later, copper strands are commonly coated with a layer of tin so that it slightly melts when heat is applied.

Cutting and Stripping UL1007 18 AWG Wire

The cutting and stripping process is completed at the same time on the wire processing machine. In this case, the insulation is only stripped on one end at 0.25” in preparation for the end user. The other end will get IDC crimped directly through the insulation, explained in the paragraph below. Some things to look for in the cutting process are measurements, scrapes on the PVC insulation and scrapes on the copper strands. Roughly 5% of the pieces should be measured during the cutting process after the machine operator is sure that the machine is set to the correct settings.

The blades that cut and strip the wire need to be set to crunch down to 0.049” as stated above when I mentioned the diameter of the copper inside the insulation. However, the machine mustn’t push the blades too far down causing strands to cut or get scraped. It’s easy to see a scraped tinned copper strand because the tin will be removed and a copper (brass look) will appear in plain view. Cut, broken or scraped copper strands can change the current, conductivity and overall settings for the end user’s application, so it’s important to put these items on a checklist for the machine operator to be aware of as they cut the wires.

IDC Crimping UL1007 18 AWG Wire

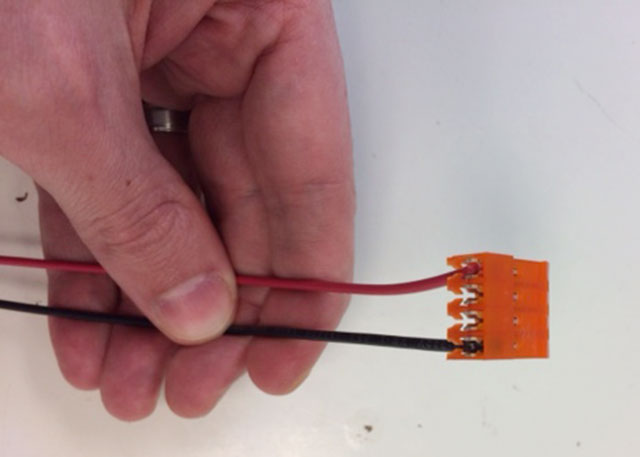

Insulation Displacement Crimping (IDC) is the process of pushing the wire into a V-shaped metal blade until the insulation is broken and the copper conductor meets the metal. Later, when this wire harness is plugged into an electronic device, it will be looking to run current through the metal and through the copper conductor to meet another connection on the other side. It’s the responsibility of the wire harness manufacturer to be sure there’s a current running through this harness, so an electronic conductivity test will suffice in terms of quality control. The video shows how the wire is pushed in to a level of 0.049” which is just enough to break through the insulation and meet the copper conductor. But again, the conductivity test will assure quality and allow the assemblers to be positive that the assembly is manufactured to the customer’s specifications.

UL1007 Wire from WesBell Electronics

If you’re looking for more information on handling and working with UL wires, then contact our expert team to learn more! We’re a leading distributor of wire and cable including UL1007, UL1015 & UL1028.