SJOOW SOOW Type G-GC Type W Portable Cord Preparation

Multiconductor Portable Cord

Multiconductor portable cord is most commonly used to make extension cords and to run power from generators (or any power source) to tools, equipment and other similar devices. Cables used to supply portable power need to be flexible so that the cable can be coiled and stored or uncoiled and used. When purchasing portable cord it’s important to think about the voltage, protection level and how you want it prepared because it will save you time and money.

Voltages and Temperatures of Multiconductor Portable Cord Products

Common voltages in this area are 300 volts, 600 volts and 2000 volts but go as high as 35,000 volts if needed. The most common 300 volt power cable is known as SJOOW (Service, Junior, Oil resistant, Oil resistant and Water resistant). Oil resistance is mentioned twice because the conductor insulation and jacket are both oil resistant, whereas only the jacket is water resistant. Junior is mentioned because it differs from SOOW which is 600 volts, so the junior version is 300 volts. SOOW is the most popular 600 volt cable that remains flexible and nearly identical to SJOOW. You might see all different variations of acronyms such as SJTOW, SJT, SJO, SEOOW, etc., but each letter shows that it has that particular attribute where “T” is Thermoplastic and “E” is Elastomer. If a letter is missing then the cable is missing that characteristic. You can review your extension cords at home to see which letters your cable has and what it might be missing in order to understand what it can and cannot resist.

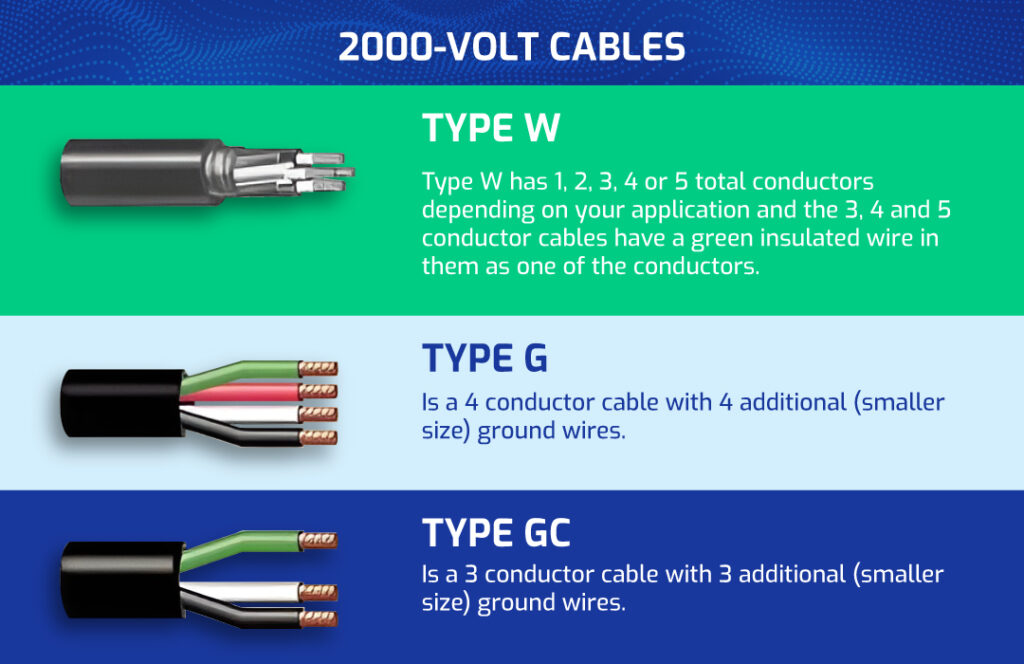

There are a few types of 2000-volt cables in this field because of large job sites and construction sites that need portable power. Type W, Type G and Type G-GC are all rated for 2000 volts and have a much thicker jacket than SJOOW and SOOW for that specific reason. Type W has 1, 2, 3, 4 or 5 total conductors depending on your application and the 3, 4 and 5 conductor cables have a green insulated wire in them as one of the conductors. The green wire is the same size as the rest but is still sometimes used as a ground wire because there aren’t any additional grounds included. Type G and G-GC, on the other hand, both have additional ground wires. Type G-GC is a 3 conductor cable with 3 additional (smaller size) ground wires. Type G is a 4 conductor cable with 4 additional (smaller size) ground wires.

Even though each of these cables are rated for different voltages the temperature rating remains very similar because they’re all used in the same application. The 300 volt SJOOW cable might be hanging off of a power drill and connected to a small generator on a construction site. However, Type G is connected to a large piece of equipment on a commercial job site where the cable will be in the same type of environment (outdoors laying on the ground). The larger cables have much thicker insulation for the increase in voltage but also for added protection against rough terrain for the potential issue of being run over by equipment on the job site.

Why is SJOOW, SOOW, Type G-GC, and Type W Portable Cord so Flexible?

Portable cord is flexible compared to some electrical cables for a few reasons. The typical reason for one over the other is settled by asking, “Will the user be handing the cable on a regular basis or will it be installed behind a wall and left there for its life?” Most electrical cables are used to bring power from telephone poles to electrical boxes, in homes or buildings. From there the wires travel to the outlets, appliances, lights and switches so that power is ready throughout the home. Since these wires run behind walls and they aren’t ever handled beyond that installation, it makes sense to spend less money during the manufacturing process to sell a less expensive cable. Multiple types of electrical cables that are purposely manufactured nonflexible are THHN, NM-B and UF-B cable. A second reason for a stiff cable is for the electricians and contractors to be able to snake the cable through tight areas behind walls. A flexible cable would quickly bunch up and prove to be difficult during installation.

On the other hand, extension cords, portable cord, hook up wire and electronic cables are typically manufactured much more flexible. Extension cords and portable cords (welding cable and stage lighting cable) are constantly used after purchasing them. Extension cords are used to supply temporary power to a certain device or piece of equipment while welding cable constantly drags across the floor or a garage to weld various projects. Stage lighting cable is set up for a particular job, torn down and reset for the next project. Many DJs and stage-setters will set up and tear down numerous stages in a month with the same cables and flexible cables are a lifesaver. Also, storing flexible cables while awaiting the next job is easier because they can be stored in smaller places.

Finally, the reason it’s more expensive to manufacture flexible cables starts with the copper strands. Imagine you have a solid piece of copper, 1” in diameter. It would be very difficult to bend at all, but it conducts a certain amount of electricity based on its 1” diameter. Now imagine 100 strands of copper (each .01” in diameter) wound tightly together to achieve a full 1” diameter. Both will conduct the same amount of electricity and both can be covered with the same insulation (for protection) but one costs more to make. Now couple the 100 flexible strands with rubber insulation compared to electrical cable PVC insulation and you end up with a much more flexible cable that can be handled regularly.