Aug 26, 2024

This is What Ground Wires Accomplish When Wiring Lights and Switches (Romex & UFB Cables)

The bare copper ground wire in Romex cables (or non-metallic sheathed cable) is a critical component of modern electrical wiring systems, providing an essential layer of safety to protect people and property from electrical hazards. Grounding in electrical systems ensures that in the event of a fault—such as a short circuit, overcurrent, or a malfunction—electricity has a safe path to the earth, preventing shocks, fires, or damage to equipment. Understanding why this wire is bare and why ground wires are sometimes green involves delving into the history, function, and regulatory standards of electrical systems.

0:13 – What does a ground wire do?

0:57 – Ground rod

1:50 – Which way electricity travels

2:25 – Outlets, Lights and washing machines

2:50 – Avoid shocking people

Purpose of the Ground Wire

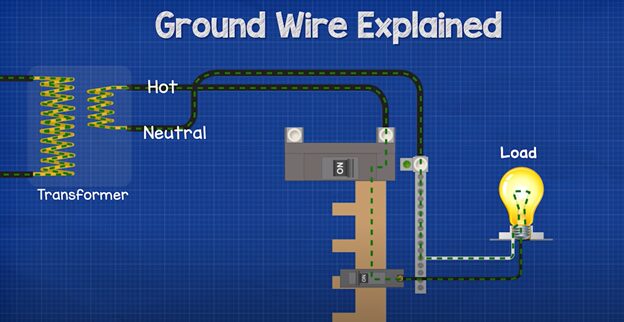

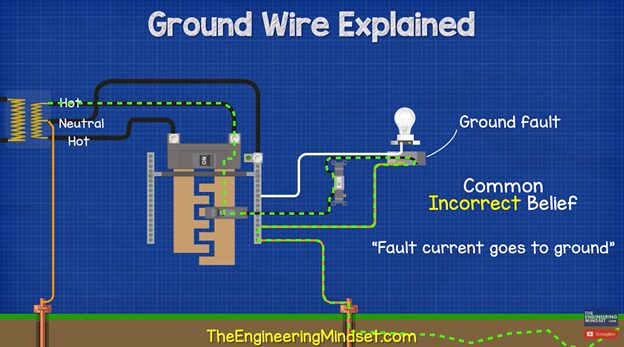

The ground wire is a safety mechanism designed to protect both electrical devices and human beings from potential electrical faults. It is a conductor that provides a direct path for electricity to flow back to the ground, typically via a grounding rod or a grounding system connected to the earth. In the case of Romex cable, the ground wire performs this essential function.

When electrical systems are functioning normally, the ground wire carries no current. However, if a fault occurs, such as when a live wire touches a metal surface, the ground wire ensures that the fault current flows directly to the earth rather than through a person or flammable material. This prevents electrical shock, burns, fires, or other catastrophic outcomes.

Why is the Ground Wire Bare in Romex Cables?

In Romex cables, the ground wire is bare for a few reasons:

- Cost Efficiency: The primary reason for leaving the ground wire bare is cost efficiency. By not adding insulation to the ground wire, manufacturers save on material and production costs. Since the ground wire does not normally carry current (except in fault conditions), insulation is not technically required. By keeping the ground wire bare, the overall cost of producing Romex cable is reduced, which translates to lower costs for electricians, contractors, and consumers.

- Simplified Installation: A bare ground wire is easier for electricians to work with during installation. It’s easier to identify the ground wire in a Romex cable because it lacks insulation, making it immediately distinguishable from the hot (usually black or red) and neutral (white) wires. This reduces the chances of incorrect wiring and speeds up the installation process.

- Regulatory Standards: Electrical codes, such as the National Electrical Code (NEC) in the United States, allow for bare ground wires in certain types of cable, including Romex. This is because the ground wire, as mentioned earlier, does not carry current during normal operation, so the need for insulation is reduced. The NEC and other international standards bodies have determined that in the context of residential and light commercial wiring, the bare ground wire in Romex provides adequate safety and performance.

- Performance in Fault Conditions: In the event of a fault, the bare ground wire performs its function without needing insulation. If there is a short circuit or another fault condition, the ground wire is designed to safely conduct the current away to the grounding system. Because the wire is made of copper, a highly conductive material, it effectively routes the fault current to the earth, reducing the risk of electric shock or fire.

Evolution of Grounding Practices

Historically, electrical systems did not always include a ground wire, which led to a greater incidence of electrical accidents, fires, and equipment damage. Grounding became more common in residential and commercial wiring in the mid-20th century as electrical safety standards evolved and technology advanced.

The inclusion of a ground wire became mandatory in most modern electrical systems due to the increased demand for safety and the recognition that grounding provided a more reliable system for dealing with faults. In the United States, for example, the NEC began requiring grounded electrical systems in the 1960s. Since then, grounding has become a standard practice, with bare copper wires commonly used in residential wiring.

Insulated Ground Wires: Why Are They Sometimes Green?

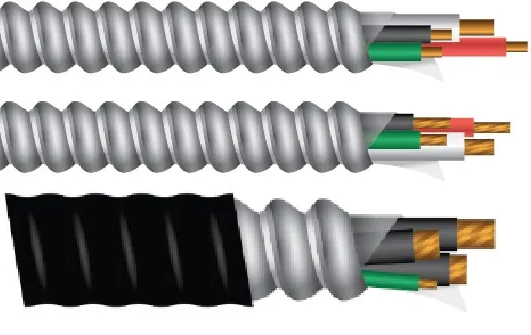

While Romex cables typically feature a bare ground wire, there are instances where ground wires are insulated, and these insulated ground wires are usually green in color. MC Cable uses a green THHN ground wire. The use of green insulation is standardized across electrical systems as a way to indicate that the wire is specifically intended for grounding purposes.

- Code and Standardization: The NEC and other electrical codes dictate that grounding conductors must be either bare or covered with green insulation. This ensures uniformity across installations, reducing the risk of confusion or error when working with electrical systems. Green is universally recognized as the color for grounding, much like white or gray indicates neutral and black or red indicates a live or “hot” wire.

- Use in Conduits and Other Applications: Insulated ground wires are more common in conduit wiring systems, where wires are run through metal or plastic tubing. In these applications, the ground wire is typically insulated to prevent it from coming into contact with other wires or the metal conduit, which could cause unintended grounding or faults. In these scenarios, having an insulated ground wire reduces the likelihood of accidental contact and ensures a cleaner, more reliable installation.

- Protection Against Corrosion: In some cases, an insulated ground wire may be used in environments where corrosion could be a concern. Bare copper wire can corrode over time, especially in moist or corrosive environments like underground or outdoor installations. Green insulation helps protect the ground wire from environmental factors that could degrade its performance over time.

- Commercial and Industrial Applications: In commercial and industrial electrical systems, insulated green ground wires are more common than in residential settings. These environments often require more robust electrical systems, with higher voltages, more complex wiring, and stricter safety standards. The insulated ground wire offers additional protection against electrical faults and ensures compliance with more stringent safety codes.

Ground Wire Safety and Best Practices

The bare ground wire in Romex cable, while a common and accepted practice, still requires careful handling and installation to ensure safety. Electricians and DIY homeowners alike must follow best practices when working with Romex cable and grounding systems to ensure proper functionality.

- Proper Grounding Connections: When installing Romex cables, the ground wire must be securely connected to the grounding system at each outlet, switch, or junction box. Typically, the bare ground wire is twisted together with the ground wires of other cables and then connected to a grounding screw or grounding clip in the electrical box. Ensuring that all ground wires are properly connected is critical for the grounding system to function as intended.

- Grounding and Bonding: In addition to connecting the ground wire to the grounding system, electricians must also ensure proper bonding between metal components, such as metal electrical boxes and conduit. Bonding ensures that all metal parts of an electrical system are at the same electrical potential, reducing the risk of electric shock.

- Compliance with Codes: Following the NEC and local electrical codes is essential when working with grounding systems. These codes provide guidelines on how to properly install, size, and connect ground wires to ensure the safety and reliability of the electrical system. For example, the NEC specifies minimum wire sizes for grounding conductors, depending on the amperage of the circuit.

- Inspection and Maintenance: Like all components of an electrical system, the ground wire and the grounding system should be regularly inspected to ensure they remain in good condition. Loose connections, corrosion, or damaged wires can compromise the effectiveness of the grounding system, so routine maintenance is important, particularly in older homes or commercial buildings.

Conclusion

The bare copper ground wire in Romex cables is an integral part of modern electrical safety. Its bare design is rooted in cost-efficiency, ease of installation, and adherence to regulatory standards. While the lack of insulation is permissible and safe in many residential and light commercial applications, green insulated ground wires are used in other scenarios to meet specific needs, such as in conduit systems or environments where additional protection is required.

Grounding is a fundamental concept in electrical systems that has evolved significantly over time. From a time when grounding was not mandatory to today’s stringent safety codes, the ground wire plays a crucial role in protecting people and property from electrical faults. The distinction between bare and green-insulated ground wires, and the contexts in which each is used, reflects the ongoing effort to ensure that electrical systems remain safe, reliable, and efficient across all types of installations.

Electricians and DIY enthusiasts alike must understand the importance of proper grounding practices and stay updated on current electrical codes to ensure safe and effective electrical system installations. Whether bare or insulated, the ground wire is a silent protector in our electrical systems, ensuring that in moments of failure, the dangers of electricity are safely channeled away from harm.

Buy bare copper ground wires here >

Buy Green THHN ground wires here >