Aug 12, 2024

5 Common Welding Cable Problems and Solutions Explained

Sure, welding cable is essential for ensuring proper electrical connections and safety in welding operations. However, several common problems can arise when using it:

- Overheating: Welding leads can overheat if they are not properly rated for the current they’re carrying. This can cause the insulation to melt or degrade, leading to potential short circuits or fire hazards. Always ensure that the cable’s gauge is appropriate for the amperage used.

- Insulation Damage: Welding cables are exposed to harsh conditions like heat, sparks, and mechanical wear. Over time, the insulation can become brittle or damaged, which can lead to electrical shorts or safety risks. Regularly inspect cables for signs of wear and replace any damaged sections. The videos below show how to complete these repairs.

- Poor Connections: Loose or corroded connections at the terminals can result in increased resistance and overheating, leading to inefficient performance and potential equipment failure. Ensure all connections are tight and free from corrosion.

- Cable Flexibility Issues: Welding cables need to be flexible to accommodate movement and handling during welding tasks. If the cable becomes stiff or inflexible, it can be difficult to maneuver, increasing the risk of damage. Store and handle cables properly to maintain their flexibility. Cold cables are less flexible. There’s an extra flex welding lead that uses 34 gauge copper strands rather than 30 gauge. WesBell uses General Cable which branded Super Vu-Tron® as the extra flex version.

- Improper Storage: Welding cables should be stored properly to avoid kinking or tangling, which can cause internal damage and reduce the lifespan of the cable. Use cable reels or other appropriate storage solutions to keep them in good condition.

Addressing these issues through proper handling, regular maintenance, and using cables that meet the required specifications can help ensure safe and efficient welding operations.

1:00 – How long welding cable lasts

4:15 – How to determine size

6:55 – Pricing comparison

7:57 – Add whips

8:30 – Splicing options

7 Methods to prevent Overheating

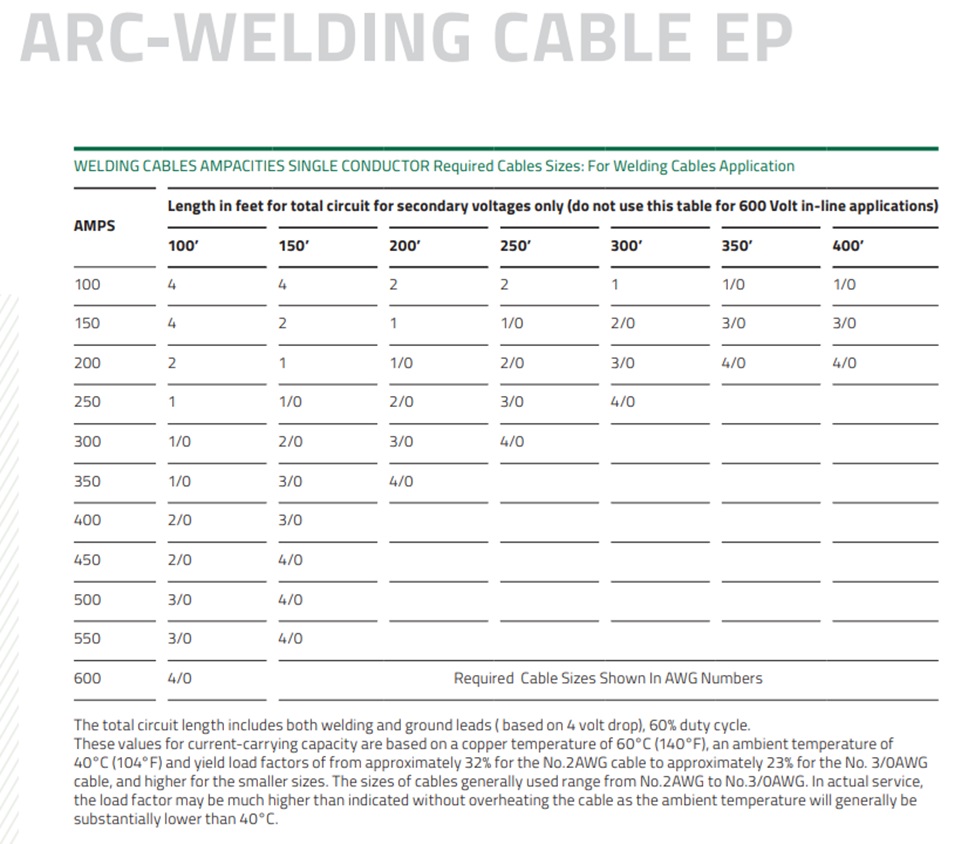

- Use Proper Cable Size: Select cables rated for the welding current to handle the load without excessive heat. Many welders recommend avoiding whips in this case.

- Minimize Cable Length: Shorten cable lengths to reduce resistance and heat buildup.

- Inspect Regularly: Check for damage or wear and replace any damaged cables immediately to prevent overheating.

- Ensure Secure Connections: Tighten and clean connections to avoid resistance that generates heat.

- Avoid Overloading: Do not exceed the machine’s rated capacity, which can cause excessive current and overheating.

- Allow Cooling Periods: Take breaks to let cables cool during prolonged use.

- Ensure Good Ventilation: Keep the work area well-ventilated to help dissipate heat.

By following these practices, you can effectively manage and prevent welding leads from overheating, ensuring safer and more efficient welding.

7 Methods to prevent Insulation Damage

- Avoid Sharp Bends: Keep cables straight or use gentle curves to prevent kinks that can damage insulation.

- Use Cable Covers: Protect cables with covers or sleeves to shield them from abrasion and impact.

- Inspect Regularly: Check cables frequently for signs of wear, cuts, or fraying and address any damage immediately.

- Keep Cables Elevated: Avoid placing cables on the ground where they can be crushed or stepped on.

- Avoid Chemical Exposure: Keep cables away from chemicals or corrosive substances that could degrade insulation.

- Proper Storage: Store cables in a clean, dry area and coil them loosely to prevent damage.

- Handle with Care: Keep cables away from sharp objects and rough surfaces that could puncture or cut insulation.

Implementing these practices will help maintain the integrity of your welding cable insulation and ensure safe and efficient operation.

6 Methods to prevent Poor Connections

- Ensure Proper Termination: Use appropriate connectors and properly crimp or solder them to the cable ends. Follow manufacturer guidelines for correct termination.

- Tighten Connections: Securely tighten all connections to avoid loose or intermittent contacts. Check connections regularly and retighten as needed.

- Inspect for Corrosion: Regularly check for signs of corrosion or oxidation at connection points. Clean and remove any corrosion to ensure good electrical contact.

- Use Quality Connectors: Invest in high-quality connectors and fittings designed for welding applications to ensure reliable connections. WesBell recommends Burndy Lugs.

- Avoid Overloading: Do not exceed the rated capacity of cables and connectors, as excessive current can lead to overheating and poor connections.

- Proper Cable Routing: Keep leads organized and avoid stressing connection points by managing cable routing to prevent mechanical strain.

By following these steps, you can ensure solid, reliable welding cable connections and maintain optimal performance.

5 Methods to ensure accurate flexibility

- Choose the Right Cable: Use welding cables specifically designed for flexibility. Look for cables with a high number of fine strands of copper, which provide greater flexibility.

- Avoid Kinks and Bends: Prevent sharp bends and kinks by handling cables carefully and using cable management tools to keep them organized.

- Proper Storage: Store cables coiled loosely and avoid tight coils or sharp angles, which can affect flexibility.

- Regular Inspection: Check cables regularly for signs of wear or damage that could affect flexibility. Replace any cables showing significant wear.

- Handle with Care: Handle cables gently to avoid stressing them, especially in extreme temperatures, which can affect flexibility.

By following these steps, you can maintain the flexibility of your welding cables, ensuring ease of use and preventing damage.

1:10 – Burnt copper strands

2:45 – Coiling makes cable hot

3:35 – How to determine size

7:00 – No Whips for solid connection

8:10 – Connect Lugs to cable

5 Methods to store Welding Cable Effectively

- Coil Loosely: Coil cables in large loops to prevent kinks and sharp bends. Use a cable reel or a spool for neat storage.

- Keep Dry: Store cables in a dry area to prevent moisture damage and corrosion. Avoid exposure to rain or high humidity.

- Avoid Extreme Temperatures: Keep cables away from extreme heat or cold, which can damage the insulation and affect flexibility.

- Protect from Physical Damage: Store cables where they won’t be crushed, stepped on, or exposed to sharp objects. Use cable covers if necessary.

- Keep Clean: Ensure cables are clean and free of debris before storing. Dirt and contaminants can cause wear over time.

By following these practices, you can extend the life of your welding cables and ensure they remain in good condition for reliable performance. Addressing these issues through proper handling, regular maintenance, and using cables that meet the required specifications can help ensure safe and efficient welding operations.

WesBell Wire and Cable Assistance

In conclusion, WesBell Wire and Cable can assist you in fitting your cable to your unique environment, and with services such as attaching lugs before shipping it. We’re an ISO9001 certified company that focuses on providing customers with long last cables by avoiding some common mistakes listed here.