Oct 11, 2024

Find a Quality Automated Wire Processing Supplier (ISO9001 Certified)

Finding a quality automated wire processing supplier that is ISO 9001 certified is a critical decision for many industries, especially those focused on manufacturing, electronics, automotive, aerospace, and medical devices. Wire processing suppliers play a key role in ensuring that wire harnesses, cable assemblies, and other wire-related products are manufactured to precise specifications, with high quality and consistency. The ISO 9001 certification ensures that these suppliers adhere to stringent quality management principles, making it a must-have requirement for many businesses.

This comprehensive guide will outline the steps to identify and evaluate a quality automated wire processing supplier that is also ISO 9001 certified.

1. Understand What You Need: Defining Your Requirements

Before beginning your search for a supplier, it’s crucial to define your specific wire processing needs. Understanding these requirements will help you narrow down the list of potential suppliers. Here’s how to get started:

a. Type of Wire Processing

Automated wire processing covers a range of services, including wire cutting, stripping, crimping, terminating, twisting, and bundling. Depending on your project, you may need one or more of these services. For example:

- Wire Harness Manufacturing: If you need complex wire harness assemblies for automotive or industrial applications, ensure that the supplier has the right equipment for cutting, crimping, and bundling multiple wires.

- Cable Assembly: For products like power cables or networking cables, the supplier should have expertise in jacket stripping, termination, and soldering.

- Custom Solutions: Some industries require custom wire processing solutions based on specific project requirements. Determine if the supplier offers customization and if they have experience in similar projects.

b. Volume and Capacity

Consider the scale of your project. Do you need wire processing services for small batches or high-volume production? The supplier must have the capability to handle your order size while maintaining consistent quality. Ask about their lead times and production capacity to ensure they can meet your deadlines.

c. Industry-Specific Needs

Certain industries like automotive, aerospace, or medical devices have unique standards and regulations. For instance, the wire processing supplier may need to follow specific protocols for durability, safety, or cleanliness. If your industry demands adherence to additional certifications beyond ISO 9001 (e.g., ISO/TS 16949 for automotive or AS9100 for aerospace), check that the supplier meets those standards.

d. Materials and Wire Types

Different applications require different wire materials such as copper, aluminum, or fiber optic cables. Confirm that the supplier is experienced in working with the specific type of wire or cable you need. Additionally, inquire about their ability to handle various wire sizes, insulation materials, and coatings.

2. Researching Potential Suppliers: Gathering Information

Once you have a clear understanding of your needs, the next step is identifying potential suppliers. This requires a combination of online research, referrals, and industry-specific resources.

a. Online Directories and Databases

There are several industry directories where you can find ISO 9001 certified wire processing suppliers. These platforms allow you to search for suppliers by certification, location, and services offered:

- ThomasNet: An industrial supplier directory that provides detailed company profiles, including certifications, capabilities, and product offerings.

- Kompass: A global B2B directory where you can search for wire processing suppliers with ISO 9001 certification.

- MFG.com: A manufacturing marketplace where you can connect with suppliers specializing in automated wire processing.

Use filters to narrow down your search by certifications, services, and geographic location. This can save time and help you identify suppliers that align with your specific requirements.

b. ISO 9001 Certified Supplier Lists

Some organizations maintain databases of ISO 9001 certified companies. Check with the International Organization for Standardization (ISO) or certification bodies in your region to find suppliers that hold ISO 9001 certification. Additionally, you can use platforms like the IAF CertSearch to verify ISO certifications.

c. Industry Referrals

Reach out to colleagues, business partners, or industry forums to get recommendations for reliable suppliers. Word-of-mouth referrals can often provide insights that you won’t find through online research. Ask about the quality of the wire processing, delivery times, and overall customer service.

3. Evaluating Quality Standards: ISO 9001 Certification and Beyond

ISO 9001 certification is a good indicator of quality, but it’s important to go beyond the certification to evaluate the supplier’s actual quality management processes.

a. Understanding ISO 9001 Certification

ISO 9001 is a global standard for quality management systems (QMS). It ensures that companies consistently meet customer and regulatory requirements while aiming for continuous improvement. Some key elements of ISO 9001 that are relevant to automated wire processing suppliers include:

- Customer Focus: The supplier should prioritize customer satisfaction by consistently delivering quality products.

- Process Approach: The supplier must have well-defined processes for all aspects of wire processing, from material handling to final inspection.

- Risk-Based Thinking: ISO 9001 requires suppliers to identify potential risks and take preventive actions to mitigate them.

- Continuous Improvement: The supplier should be committed to improving their processes and products over time.

b. Supplier Audits and Quality Control

While ISO 9001 certification is important, you should also ask about additional quality control measures in place. Consider the following:

- Quality Audits: Check if the supplier conducts regular internal and external audits to ensure compliance with their quality management system.

- Inspection Processes: Inquire about their inspection procedures, both during and after production. Do they conduct 100% inspections, or are inspections done on a sample basis? What tools and equipment do they use for quality testing?

- Traceability: Verify that the supplier maintains traceability of materials, batches, and production runs, especially if your industry requires detailed documentation for compliance.

c. Additional Certifications

While ISO 9001 is essential, other certifications may be relevant depending on your industry. For example:

- ISO/TS 16949: This certification is specific to the automotive industry and ensures that suppliers meet the high-quality standards required for automotive wire harnesses and assemblies.

- AS9100: Required for aerospace and defense industries, this certification ensures that wire processing suppliers meet stringent safety and quality standards for mission-critical applications.

- ISO 13485: If you’re sourcing wire processing for medical devices, this certification is vital as it covers quality management specific to medical devices.

4. Assessing Technology and Automation Capabilities

The primary advantage of choosing an automated wire processing supplier is the efficiency, precision, and consistency that automation brings. However, not all suppliers are created equal in terms of their technological capabilities. To ensure you are selecting a supplier that is technologically equipped for your needs, consider the following aspects:

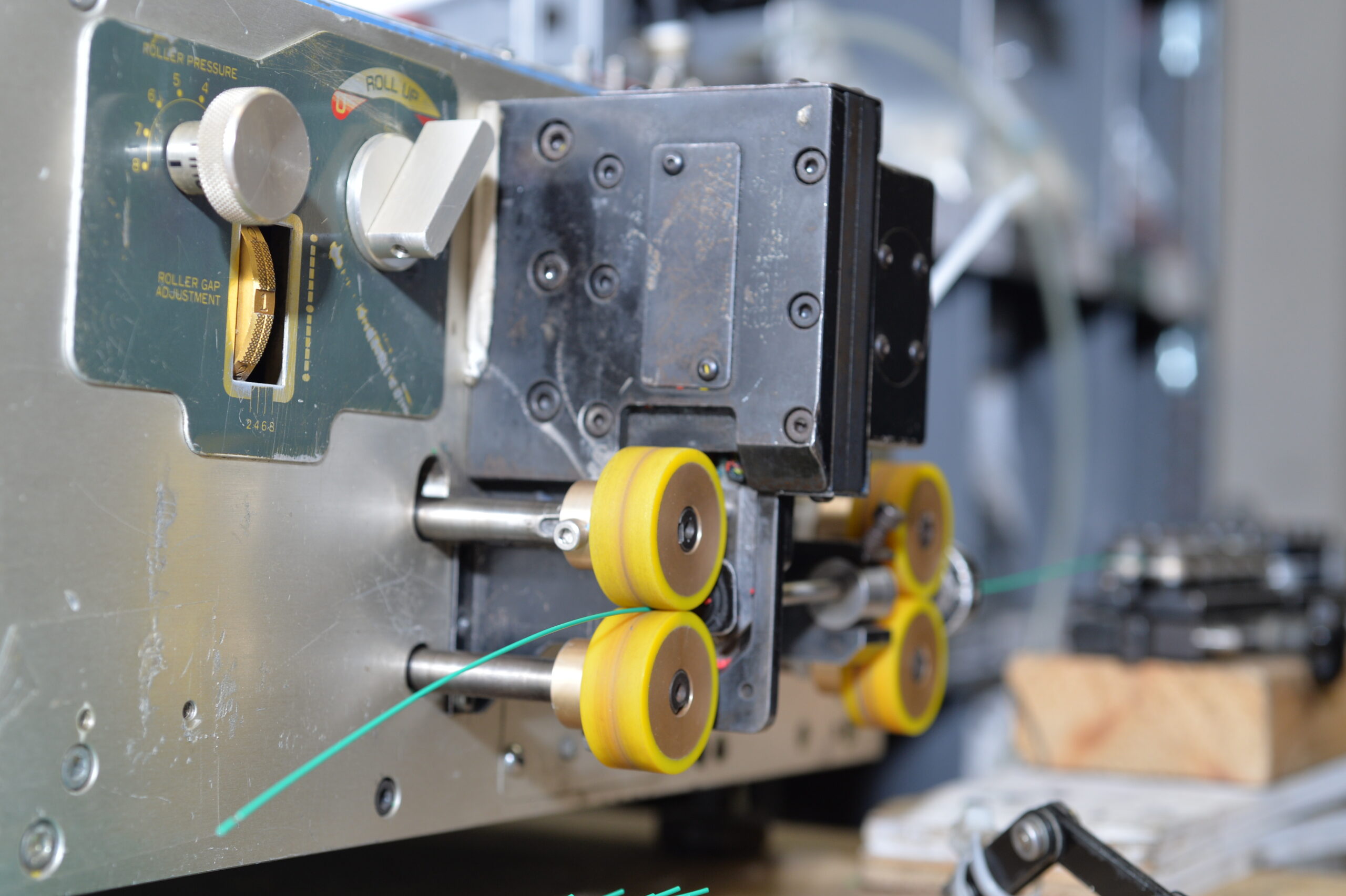

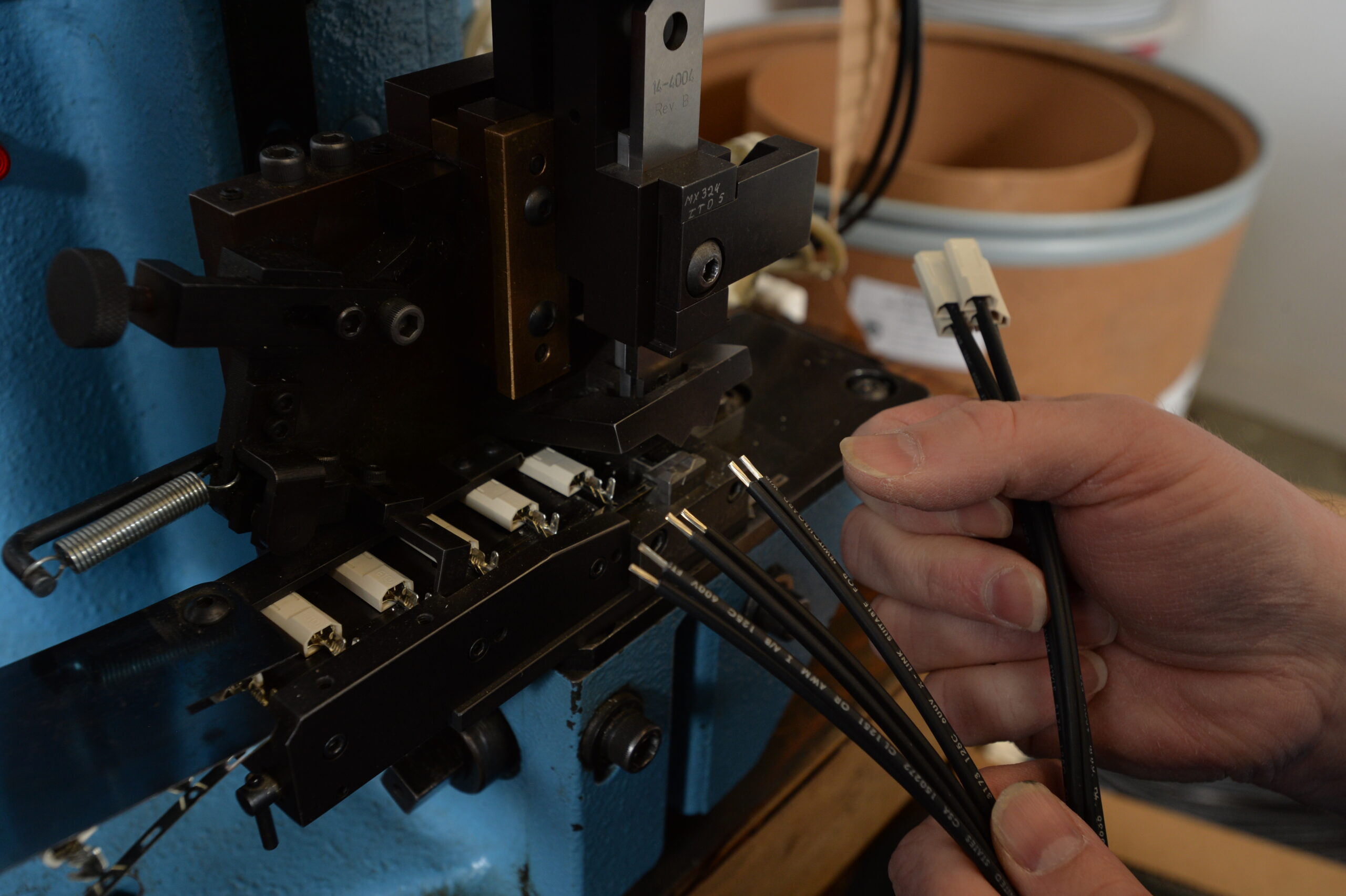

a. Types of Automation Equipment

The supplier’s machinery and automation tools are a direct reflection of their processing capabilities. Ask about the specific types of machines they use for cutting, stripping, crimping, terminating, or other processes. Some common technologies include:

- CNC Wire Processing Machines: Computer numerical control (CNC) machines offer high precision and are ideal for complex wire harnesses.

- Laser Wire Stripping: Laser stripping technology is especially useful for wires with delicate insulation or for medical applications where precision is critical.

- Robotic Wire Handling: Advanced automation systems may incorporate robotics for wire feeding, inspection, and assembly.

Check if the supplier has the latest technology or if they invest in upgrading their equipment to keep up with advancements in wire processing automation.

b. Customization Capabilities

Some projects may require custom wire processing solutions. Inquire about the supplier’s ability to modify their machinery or production processes to accommodate unique project requirements. Suppliers with flexible, modular automation systems are better equipped to handle custom requests.

5. Supplier Communication and Support: Ensuring a Strong Partnership

Clear communication and reliable customer support are essential for maintaining a productive relationship with your wire processing supplier. Evaluate how well a supplier communicates and supports your project needs.

a. Initial Response and Consultation

When you first contact a potential supplier, note how quickly and thoroughly they respond. A quality supplier should be willing to offer a detailed consultation, discussing your requirements and suggesting solutions based on their expertise. They should also be able to provide accurate quotes and lead times.

b. Project Management

For large or ongoing projects, a dedicated project manager is invaluable. Ask if the supplier assigns a project manager to your account who can oversee the entire production process, handle troubleshooting, and coordinate logistics. This level of support ensures that your project stays on schedule and any issues are quickly resolved.

c. After-Sales Support

Post-delivery support is just as important as the initial service. A good supplier should offer technical support, troubleshooting, and maintenance services, especially for long-term or repeat customers. They should also have a system in place for handling returns or replacements if any quality issues arise.

6. Requesting Samples and Prototypes: Testing Before Commitment

Before committing to a long-term contract or large order, it’s advisable to request samples or prototypes. This allows you to assess the supplier’s quality and suitability for your project.

a. Prototype Testing

If you are developing a new product, a prototype phase is essential. Ask if the supplier offers prototype services and how quickly they can deliver a sample. Test the prototype for functionality, durability, and compliance with your specifications. If necessary, request modifications before proceeding with full-scale production.

b. Quality of Samples

Carefully inspect the sample for quality issues such as poor insulation stripping, incorrect crimping, or damage during transport. This is your chance to assess whether the supplier can meet your exacting standards for production.

Conclusion

Finding a quality automated wire processing supplier that is also ISO 9001 certified requires a systematic approach that combines research, evaluation, and testing. By understanding your specific needs, researching potential suppliers, verifying certifications, and assessing quality control processes, you can find a partner that not only meets your technical requirements but also delivers reliable, high-quality wire processing services.

Key steps include:

- Defining your wire processing needs based on your project, volume, and industry.

- Using industry directories, ISO databases, and referrals to find potential suppliers.

- Evaluating ISO 9001 certification along with other industry-specific certifications.

- Assessing the supplier’s automation capabilities and customization options.

- Ensuring strong communication, project management, and after-sales support.

- Testing samples and prototypes before committing to a long-term partnership.

By following these steps, you’ll be well-positioned to choose a wire processing supplier that adds value to your supply chain, delivers quality products, and meets your industry’s highest standards, in this case, within the hook up wire industry where processing is provided.