Oct 3, 2024

How to Qualify and Choose Wire Harness Manufacturers for Outsourcing

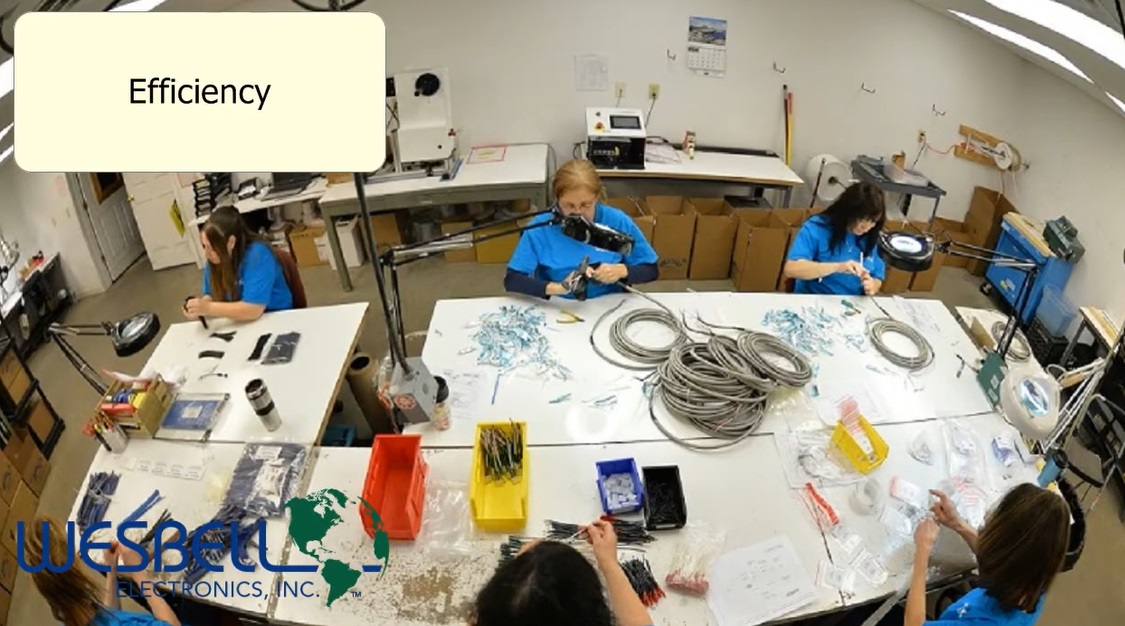

Outsourcing wire harness manufacturing can help businesses improve efficiency, reduce costs, and focus on core competencies. However, selecting the right wire harness manufacturer requires a thorough evaluation process to ensure product quality, reliability, and long-term partnerships. In this guide, we will delve into the key factors you should consider when qualifying and choosing a wire harness manufacturer. We’ll cover the following aspects:

- Understanding Wire Harness Requirements

- Supplier Qualification Process

- Compliance and Certifications

- Manufacturing Capabilities

- Quality Control Measures

- Supply Chain and Logistics

- Cost Evaluation and Quoting

- Supplier Relationships and Communication

- Technology and Innovation

- Case Studies and References

- Environmental and Sustainability Considerations

1. Understanding Wire Harness Requirements

Before you begin the process of qualifying wire harness manufacturers, it is crucial to define the specific requirements of your wire harness assembly. These include:

- Electrical and Mechanical Specifications: Consider the voltage, current, signal integrity, and environmental conditions the wire harness will encounter.

- Materials: Ensure the manufacturer can handle specific materials such as copper, aluminum, insulation types (PVC, PTFE), and connectors.

- Complexity: Evaluate whether the harness involves custom connectors, routing requirements, or complex shielding.

- Volume: Define whether you require small, medium, or high-volume production and ensure the manufacturer is capable of scaling according to your needs.

By having a clear understanding of these factors, you can set clear expectations and focus on manufacturers that specialize in your requirements.

2. Supplier Qualification Process

The supplier qualification process involves assessing potential wire harness manufacturers’ capabilities, reliability, and financial stability. Key steps include:

- Preliminary Research: Begin by gathering information from multiple manufacturers, including online research, industry databases, and professional networks.

- Site Visits and Audits: Visit the facilities of shortlisted manufacturers to assess their equipment, production processes, and quality control systems.

- Financial Health: Ensure the manufacturer is financially stable by reviewing financial records, client portfolios, and performance histories to avoid disruption in supply.

- Legal and Compliance Checks: Verify that the manufacturer complies with legal requirements, including labor laws, safety regulations, and contractual obligations.

Conducting thorough due diligence will minimize risks and ensure a long-term and reliable outsourcing relationship.

3. Compliance and Certifications

Certifications are critical indicators of a wire harness manufacturer’s commitment to quality and regulatory standards. Consider the following:

- ISO 9001: A globally recognized quality management standard, ISO 9001 certification ensures that the manufacturer maintains quality control and continuous improvement.

- IATF 16949: For the automotive industry, this certification focuses on quality systems in manufacturing and can be a key factor when outsourcing wire harnesses for vehicles.

- UL Certification: For products used in safety-critical environments, UL (Underwriters Laboratories) certification ensures compliance with safety standards.

- IPC/WHMA-A-620: This standard outlines the requirements for the manufacture of wire harnesses and cable assemblies, ensuring proper workmanship and quality.

- RoHS/REACH Compliance: Check if the manufacturer adheres to environmental regulations regarding hazardous substances, particularly if you are operating within the EU.

Verifying certifications ensures that your wire harnesses will meet both industry and regulatory standards, ensuring safety and reliability.

4. Manufacturing Capabilities

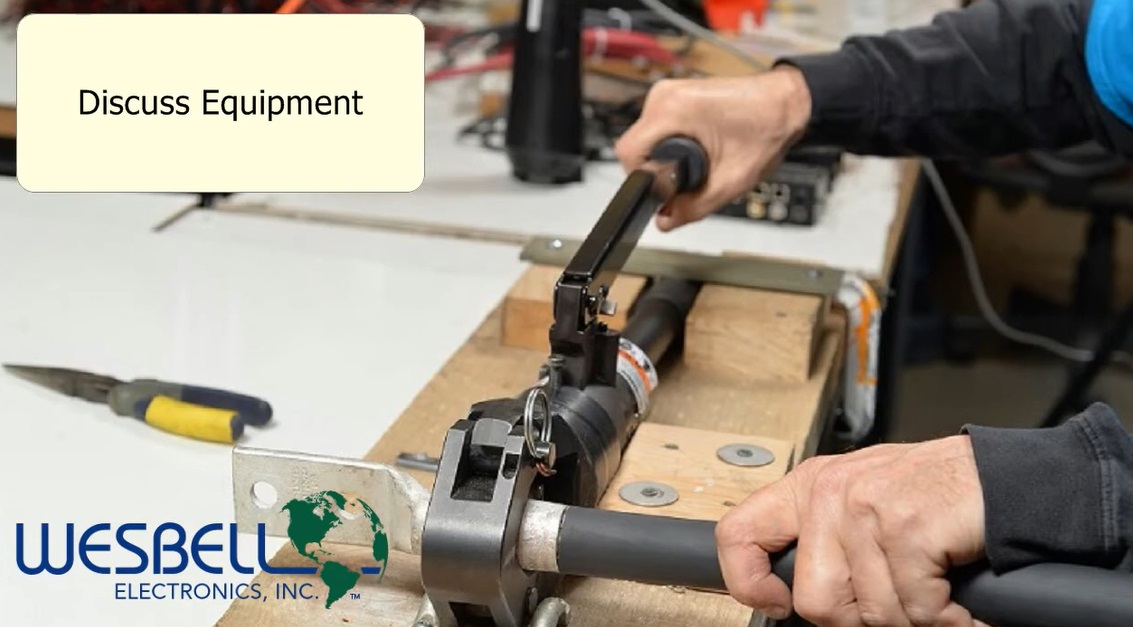

The technical capabilities of a wire harness manufacturer should match your project requirements. Evaluate the following aspects:

- Machinery and Automation: Does the manufacturer use advanced machinery, automation, and tools such as laser wire stripping, automated crimping, and ultrasonic welding?

- Prototyping and Design Support: Can the manufacturer assist with the design, development, and testing of prototypes before mass production?

- Specialization: Look for manufacturers that have experience in your specific industry, such as aerospace, automotive, or medical devices, as these industries often have specialized requirements.

- Customization: Ensure the manufacturer can handle custom designs, specific connector systems, and unique harness configurations.

- Capacity and Scalability: The manufacturer should be able to handle both your current production volumes and future growth. Investigate their lead times, production flexibility, and ability to scale up operations when necessary.

These capabilities are critical in ensuring that the manufacturer can meet both the complexity and the volume of your wire harness needs.

5. Quality Control Measures

Quality is non-negotiable when outsourcing wire harness manufacturing. Evaluate a manufacturer’s quality control systems, including:

- Inspection Processes: Check if the manufacturer has robust incoming, in-process, and final inspections in place to ensure each harness meets required specifications.

- Testing Equipment: Verify whether the manufacturer has appropriate testing equipment such as continuity testers, high-voltage testers, and automated testing systems.

- Traceability: Ensure the manufacturer uses traceability systems to track raw materials and components back to their source, which is essential for quality assurance and risk management.

- Defect Resolution Process: Investigate how the manufacturer handles non-conforming products and what corrective actions are taken to avoid future issues.

- Lean Manufacturing and Six Sigma: Assess if the manufacturer uses lean manufacturing or Six Sigma practices to minimize waste and optimize efficiency.

A strong quality control system will reduce defects, minimize rework, and enhance the performance and reliability of your wire harness assemblies.

6. Supply Chain and Logistics

A well-optimized electrical wire supply chain is crucial for timely delivery and cost control. Consider the following:

- Geographical Location: Manufacturers located closer to your operations or end market can help reduce lead times and shipping costs. Offshore manufacturing can offer cost savings but may present longer lead times and communication challenges.

- Supplier Networks: Ensure the manufacturer has strong relationships with reliable suppliers of raw materials, such as wires, connectors, and terminals, which directly impacts quality and lead times.

- Inventory Management: Does the manufacturer offer just-in-time (JIT) inventory systems or kanban methods for inventory control? These systems can help manage stock efficiently and reduce storage costs.

- Logistics Support: Evaluate whether the manufacturer can handle the logistics of shipping, customs clearance, and warehousing, particularly for international shipping.

The efficiency of the supply chain and logistics operations will directly impact your project’s costs and delivery schedules.

7. Cost Evaluation and Quoting

Cost is a critical factor in selecting a wire harness manufacturer, but it should be considered alongside quality and reliability. Here are key steps to take:

- Request for Quotation (RFQ): Issue an RFQ to multiple manufacturers and ask for detailed breakdowns of material, labor, overhead, and other costs.

- Hidden Costs: Be aware of hidden costs such as tooling fees, setup charges, or minimum order quantities (MOQs).

- Total Cost of Ownership (TCO): Consider not just the upfront cost but also the long-term costs associated with quality control, shipping, delays, and warranty claims.

- Price Negotiations: Engage in negotiations, but ensure that cost reductions do not compromise quality. Ask about opportunities for cost savings in areas like bulk ordering or long-term contracts.

- Currency Fluctuations: If outsourcing to an overseas manufacturer, consider how currency exchange rates could affect the overall cost.

A comprehensive cost analysis ensures that you get the best value for your investment while maintaining product quality.

8. Supplier Relationships and Communication

Effective communication and collaboration are key to a successful outsourcing relationship. Evaluate:

- Response Times: How quickly does the manufacturer respond to queries or resolve issues? A manufacturer with poor communication may cause delays and misunderstandings.

- Dedicated Account Manager: Does the manufacturer assign a dedicated account manager to your project? Having a single point of contact improves communication efficiency.

- Cultural and Language Barriers: When dealing with offshore manufacturers, consider potential challenges related to language and cultural differences. These can impact communication, quality expectations, and work practices.

- Partnership Approach: A good manufacturer will treat the relationship as a partnership, actively contributing to design improvements, cost savings, and long-term collaboration.

- After-Sales Support: Ensure that the manufacturer offers adequate support after the sale, including help with warranty claims, repair services, and technical guidance.

Strong supplier relationships ensure smooth project execution and long-term success.

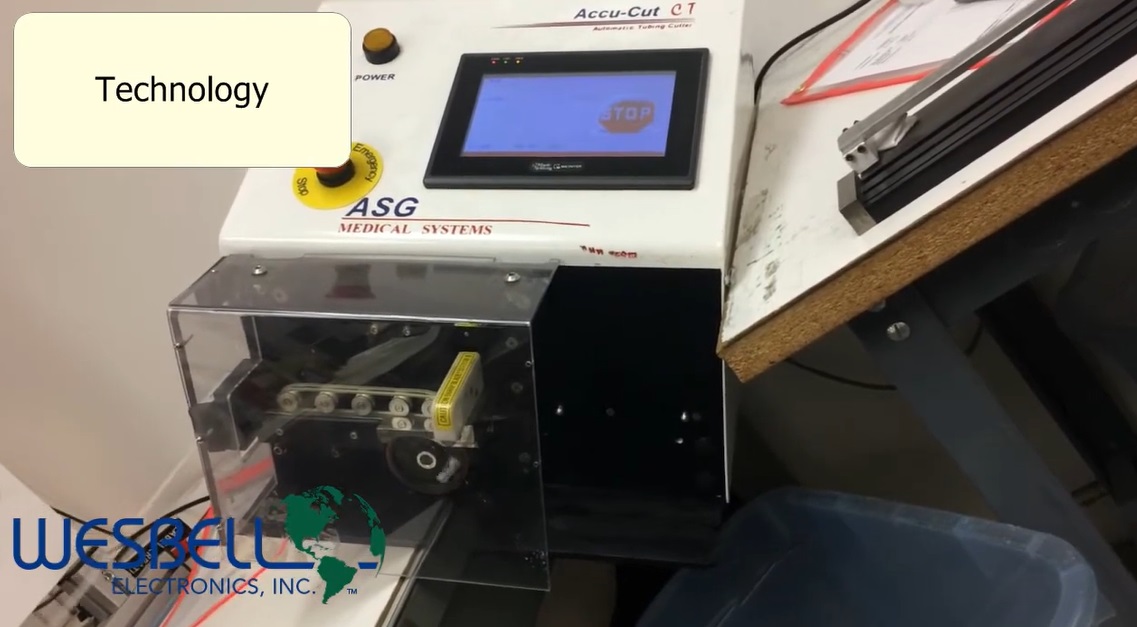

9. Technology and Innovation

In a rapidly evolving industry, technological advancements can offer significant advantages. Consider whether the manufacturer is:

- Adopting New Technologies: Evaluate whether the manufacturer is using cutting-edge technologies like 3D printing for prototyping, IoT-connected equipment for production monitoring, or advanced automation.

- Investing in R&D: Check if the manufacturer has an R&D department focused on innovation, which can help with the development of more efficient, reliable, and cost-effective wire harness solutions.

- ERP and Data Management Systems: Ensure the manufacturer uses Enterprise Resource Planning (ERP) systems to streamline operations, improve data accuracy, and enhance communication.

- Green Technologies: Some manufacturers invest in eco-friendly production methods, such as energy-efficient machines and recyclable materials, which may align with your company’s sustainability goals.

Manufacturers that invest in innovation are better positioned to deliver superior quality and adapt to changing industry trends.

10. Case Studies and References

A reliable way to assess a manufacturer’s capabilities is to review case studies and speak with previous clients. Ask for:

- Case Studies: Request detailed case studies showing how the manufacturer has handled similar projects, particularly in terms of complexity, volume, and industry-specific requirements.

- References: Speak with clients from industries similar to yours to gain insights into the manufacturer’s performance, reliability, and ability to meet deadlines.

- Success Stories: Inquire about success stories where the manufacturer helped clients reduce costs, improve product quality, or increase production efficiency.

Testimonials from existing clients offer a glimpse into the manufacturer’s track record and reliability.

11. Environmental and Sustainability Considerations

With increasing focus on sustainability, it’s important to evaluate a manufacturer’s environmental practices:

- Eco-Friendly Materials: Does the manufacturer use environmentally friendly materials, such as recyclable insulation or lead-free solder?

- Energy Efficiency: Assess whether the manufacturer uses energy-efficient equipment and processes.

- Waste Management: Check how the manufacturer handles waste, particularly hazardous materials, and whether they comply with waste disposal regulations.

- Carbon Footprint: Some manufacturers may offer initiatives to reduce their carbon footprint, such as sourcing materials locally or investing in renewable energy.

Choosing a manufacturer with strong environmental practices can align with your corporate social responsibility (CSR) goals and appeal to eco-conscious consumers.

Conclusion

Choosing the right wire harness manufacturer for outsourcing requires a comprehensive evaluation of their technical capabilities, quality control measures, certifications, cost structures, and supplier relationships. By taking the time to thoroughly qualify potential manufacturers, you can ensure a reliable, cost-effective, and long-term partnership that will contribute to your company’s success.

In summary, prioritize manufacturers that:

- Have proven expertise in your industry.

- Offer certifications that ensure quality and safety compliance.

- Have robust quality control and traceability systems.

- Maintain strong supply chain management and inventory practices.

- Provide transparency in cost breakdowns and communication.

This detailed, methodical approach will ultimately result in better wire harnesses, reduced risk, and a smooth outsourcing experience.