Sep 13, 2024

2 Types of Service Wire Explained (SJOOW and SOOW)

SOOW and SJOOW are types of flexible portable cords used in a variety of industrial, commercial, and residential applications. Both are highly regarded for their durability and flexibility, making them suitable for tough environments. However, they have distinct characteristics that make them suited to different purposes. Understanding the similarities and differences between SOOW and SJOOW cables is essential when choosing the right type of service wire for a specific application. In this guide, we will explore the core features, similarities, and key differences between SOOW and SJOOW, providing a comprehensive understanding of their applications, construction, and specifications.

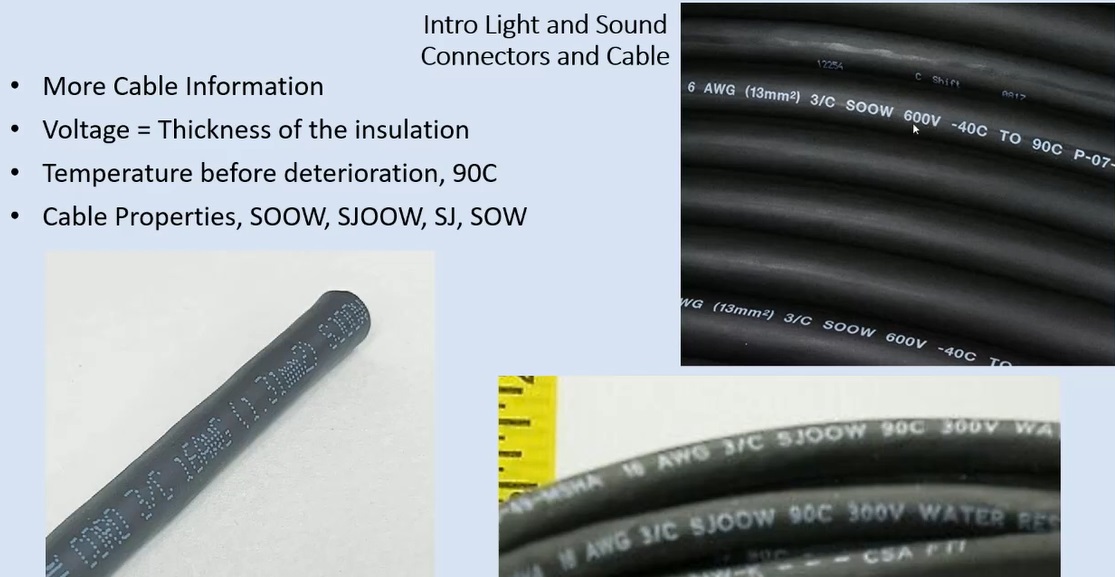

0:00 – Cable printing

0:30 – Voltage ratings

1:15 – Temperature Ratings

2:05 – SOOW and SJOOW

1. Overview of SOOW and SJOOW Cables

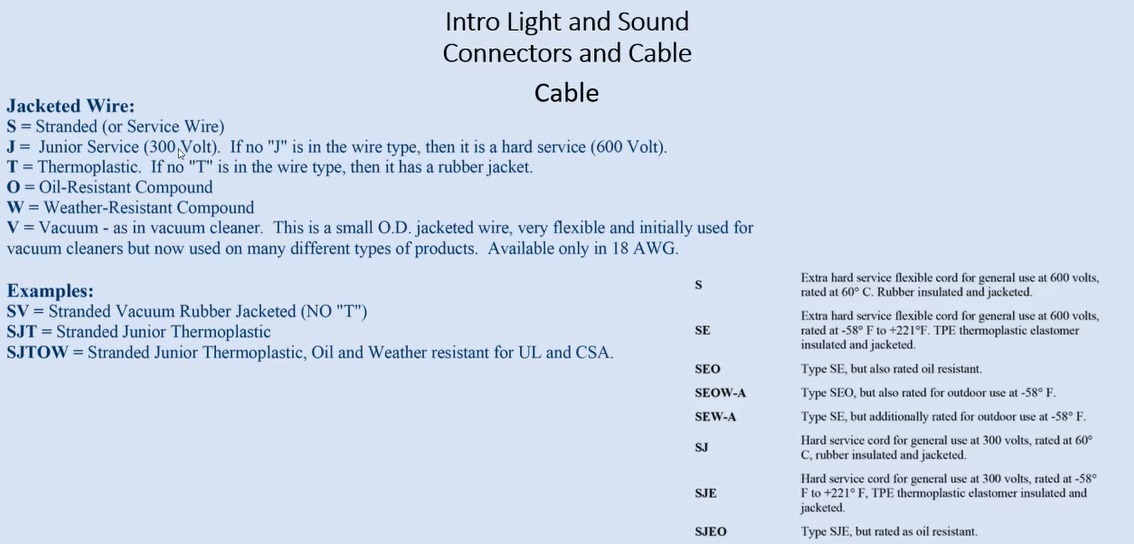

SOOW Cable: SOOW cable is a heavy-duty, multi-conductor portable cord with a robust design. The designation “SOOW” stands for:

- S = Service cord.

- OO = Oil-resistant insulation and oil-resistant jacket.

- W = Weather and water-resistant.

SOOW cables are highly durable, offering resistance to oils, chemicals, and weather conditions. This makes them ideal for industrial settings where the cable will be exposed to harsh environments, moisture, and wear and tear. They are commonly used in mining, construction, and other heavy-duty applications.

SJOOW Cable: SJOOW cable, on the other hand, is similar in design but with lighter-duty specifications. The “SJOOW” designation stands for:

- S = Service cord.

- J = Junior service (300V rating).

- OO = Oil-resistant insulation and oil-resistant jacket.

- W = Weather and water-resistant.

SJOOW is used in applications where a lower voltage (300V compared to SOOW’s 600V) is sufficient. It is also more lightweight and flexible than SOOW, making it suitable for portable equipment, household tools, and other less intense industrial applications.

2. Similarities Between SOOW and SJOOW Cables

There are several commonalities between SOOW and SJOOW cables, given their design and intended use as flexible, durable cords. Some key similarities include:

2.1 Conductor Materials

Both SOOW and SJOOW cables typically feature conductors made from stranded copper. Stranded copper conductors provide excellent electrical conductivity while maintaining flexibility, which is crucial for applications requiring frequent movement and bending of the cable.

2.2 Insulation and Jacket Materials

Both types of cables have thermoset rubber insulation and a thermoset jacket. This material ensures that the cables can withstand extreme temperatures, exposure to oils, chemicals, and abrasion, and retain their flexibility even in cold environments.

- Oil Resistance: The double “O” in both SOOW and SJOOW means that the insulation and jacket are oil-resistant. This is important in environments like factories, workshops, and other industrial settings where contact with oil is common.

- Weather and Water Resistance: The “W” in both cable types signifies weather and water resistance. This makes them suitable for outdoor use in wet environments, such as temporary power setups for outdoor events, construction sites, or equipment exposed to the elements.

2.3 Temperature Range

Both SOOW and SJOOW cables can operate in extreme temperatures. While the exact range may vary slightly depending on the manufacturer, a typical operating range is -40°C to 90°C (-40°F to 194°F). This temperature tolerance makes them suitable for both indoor and outdoor environments in a variety of climates.

2.4 Flexibility

Both cables are known for their flexibility, thanks to the stranded copper conductors and rubber insulation. This makes them easy to handle, install, and maneuver in spaces where rigid cables would be impractical or unsafe.

3. Key Differences Between SOOW and SJOOW Cables

Despite the similarities, several important differences set SOOW and SJOOW cables apart. These differences influence where and how each cable type should be used.

3.1 Voltage Rating

The most notable difference between SOOW and SJOOW cables is the voltage rating:

- SOOW cables are rated for 600 volts.

- SJOOW cables are rated for 300 volts.

This difference makes SOOW suitable for heavy-duty applications where high voltage is required, such as in industrial equipment, large machinery, and construction sites. SJOOW, with its lower voltage rating, is better suited for lighter-duty tasks, such as powering small appliances, portable tools, and extension cords.

3.2 Durability and Robustness

While both cables are durable, SOOW is designed to withstand more rigorous conditions due to its higher voltage rating and thicker construction. SOOW cables often have a thicker jacket and more robust insulation, which provides added protection against abrasion, impact, and extreme environments.

- SOOW Cables: Better suited for environments that involve heavy machinery, mining operations, and areas where the cable will experience significant mechanical stress.

- SJOOW Cables: More appropriate for general-purpose applications or situations where flexibility and lighter construction are more important than extreme durability.

3.3 Size and Flexibility

Because SOOW cables are heavier and have thicker insulation, they are generally less flexible than SJOOW cables. SJOOW’s lighter construction makes it more flexible, which is advantageous in applications where the cable needs to be moved frequently or installed in tight spaces.

3.4 Cost

Another important distinction is cost. Due to its heavier construction and higher voltage rating, SOOW is typically more expensive than SJOOW. The higher price of SOOW reflects its greater durability and ability to handle more intense electrical loads. For budget-conscious projects where the higher voltage rating and extreme durability are not necessary, SJOOW can be a more cost-effective solution.

3.5 Weight

SOOW cables are generally heavier than SJOOW cables, due to the thicker insulation and jacket required to support higher voltage applications and withstand more extreme conditions. The added weight can be a factor in installations where cable weight needs to be minimized, such as in portable tools or applications where frequent movement is required.

4. Applications of SOOW and SJOOW Cables

4.1 SOOW Cable Applications

Because of its higher voltage rating and more robust construction, SOOW cables are often used in heavy-duty industrial environments, including:

- Construction Sites: For powering heavy machinery and equipment.

- Mining: Where cables are exposed to harsh conditions, chemicals, and heavy wear.

- Marine Applications: Due to their water resistance and durability in tough conditions.

- Portable Power Distribution: Used in temporary power setups for events, construction, or emergency power.

4.2 SJOOW Cable Applications

SJOOW cables, with their lower voltage rating and more flexible construction, are more commonly used in lighter-duty applications such as:

- Portable Tools and Equipment: Ideal for use with handheld tools and portable devices that require flexibility.

- Household Appliances: Used for power cords in appliances that don’t demand a high voltage rating.

- Extension Cords: SJOOW is often used in making flexible and durable extension cords for residential and light commercial use.

- Small Motors and Generators: Suitable for powering small motors, generators, and other equipment where lower voltage is sufficient.

5. Selecting Between SOOW and SJOOW

When choosing between SOOW and SJOOW, consider the following factors:

- Voltage Requirements: If your application requires a voltage higher than 300V, SOOW is the only choice, as SJOOW is only rated for 300V.

- Durability: For harsh environments involving chemicals, oil exposure, or significant physical stress, SOOW offers better protection. If the environment is less demanding, SJOOW will suffice.

- Flexibility: For applications where flexibility is key, especially in portable or handheld devices, SJOOW’s lighter construction may be more suitable.

- Cost Consideration: SOOW is generally more expensive due to its heavy-duty nature, so if your application doesn’t require the added durability, SJOOW can be a more budget-friendly option.

6. Safety Considerations

Both SOOW and SJOOW cables are designed with safety in mind, but it’s important to select the correct cable for your specific application. Using a cable with a lower voltage rating (such as SJOOW) in an application that requires higher voltage could lead to electrical failure, fire hazards, or equipment damage. Similarly, using a less durable cable in a harsh environment could lead to physical damage and exposure to live conductors, posing a safety risk.

Conclusion

SOOW and SJOOW cables are both versatile, flexible, and durable, but they cater to different needs. SOOW, with its 600V rating and more rugged construction, is ideal for heavy-duty industrial environments, while SJOOW, with its 300V rating, is better suited for lighter-duty, more portable applications. Understanding these differences allows for the selection of the right cable for your specific application, balancing factors like voltage requirements, durability, flexibility, and cost. Whether you need a cable for powering heavy machinery on a construction site or for use with portable tools in a workshop, knowing when to use SOOW or SJOOW will ensure safety, efficiency, and cost-effectiveness.