Aug 31, 2024

Comparing PVC Lead Wire to PTFE (Teflon Coated) Hook up Wire

In electrical and electronic engineering, the choice of wire insulation is critical for the durability, safety, and performance of a project. Two common types of wire insulation are PVC (Polyvinyl Chloride) and PTFE (Polytetrafluoroethylene, commonly known as Teflon). Both materials are widely used for different applications, and understanding their properties, advantages, and limitations can help in selecting the right wire for specific needs.

This article will delve into the characteristics of PVC and PTFE lead wires, comparing and contrasting them based on various factors like thermal stability, flexibility, chemical resistance, and more. Additionally, it will cover the methods of cutting and stripping these wires using a wire processing machine.

1. Material Composition and Properties

1.1 PVC (Polyvinyl Chloride)

PVC is a thermoplastic polymer widely used for insulation in electrical wires. It is known for its durability, cost-effectiveness, and versatility. The properties of PVC include:

- Thermal Stability: PVC can withstand temperatures up to 105°C. However, it may degrade under prolonged exposure to higher temperatures.

- Flexibility: PVC is relatively flexible, which makes it easy to handle and install in various applications.

- Chemical Resistance: PVC has good resistance to acids, alkalis, and oils but may not be suitable for environments with strong organic solvents.

- Electrical Insulation: PVC provides good electrical insulation, which is why it’s commonly used in household and industrial wiring.

- Cost: PVC is inexpensive and widely available, making it a popular choice for many applications.

1.2 PTFE (Polytetrafluoroethylene)

PTFE, known by the brand name Teflon, is a fluoropolymer with excellent thermal, chemical, and electrical properties. It is often used in high-performance applications where these characteristics are crucial. The properties of PTFE include:

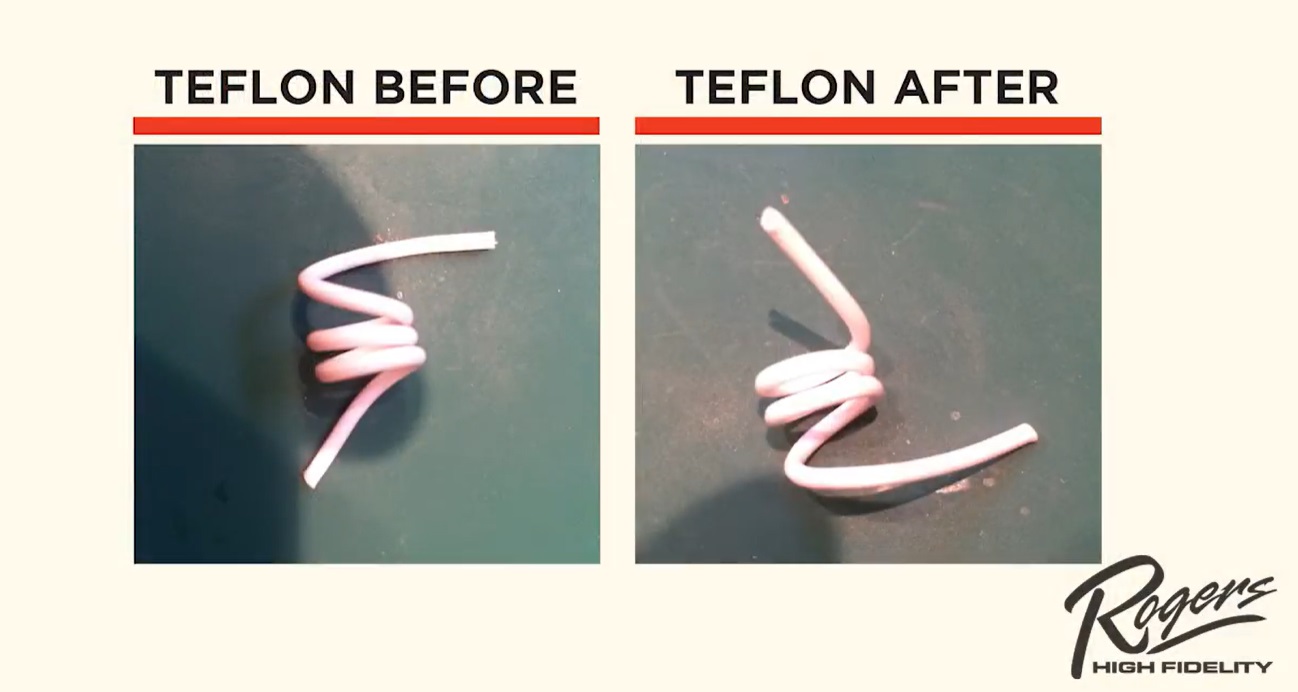

- Thermal Stability: PTFE can withstand temperatures up to 260°C, making it suitable for high-temperature environments.

- Flexibility: PTFE is less flexible compared to PVC, especially at room temperature. However, it maintains its properties over a broader temperature range.

- Chemical Resistance: PTFE is highly resistant to almost all chemicals, including strong acids, alkalis, and organic solvents.

- Electrical Insulation: PTFE offers superior electrical insulation, with a high dielectric strength and low dielectric constant.

- Cost: PTFE is more expensive than PVC due to its advanced properties and specialized manufacturing processes.

2. Applications

2.1 Applications of PVC Lead Wire

PVC lead wires are commonly used in a wide range of applications, including:

- Household Wiring: Due to its cost-effectiveness and ease of use, PVC is widely used in residential wiring.

- Automotive Wiring: PVC is also used in automotive wiring harnesses where the operating temperatures are within the safe range for PVC.

- Consumer Electronics: PVC-insulated wires are found in various consumer electronics, including household appliances and personal gadgets.

2.2 Applications of PTFE Lead Wire

PTFE lead wires are used in more demanding applications, such as:

- Aerospace and Defense: PTFE is ideal for aerospace applications where wires must withstand extreme temperatures and harsh chemical environments.

- High-Frequency Electronics: Due to its excellent electrical properties, PTFE is often used in RF and microwave transmission lines.

- Medical Devices: PTFE’s biocompatibility and resistance to sterilization processes make it suitable for medical device wiring.

3. Advantages and Disadvantages

3.1 Advantages of PVC Lead Wire

- Cost-Effective: PVC is less expensive, making it accessible for a wide range of applications.

- Flexibility: Easy to install and route through various environments.

- Availability: PVC is widely available and comes in numerous sizes and colors.

3.2 Disadvantages of PVC Lead Wire

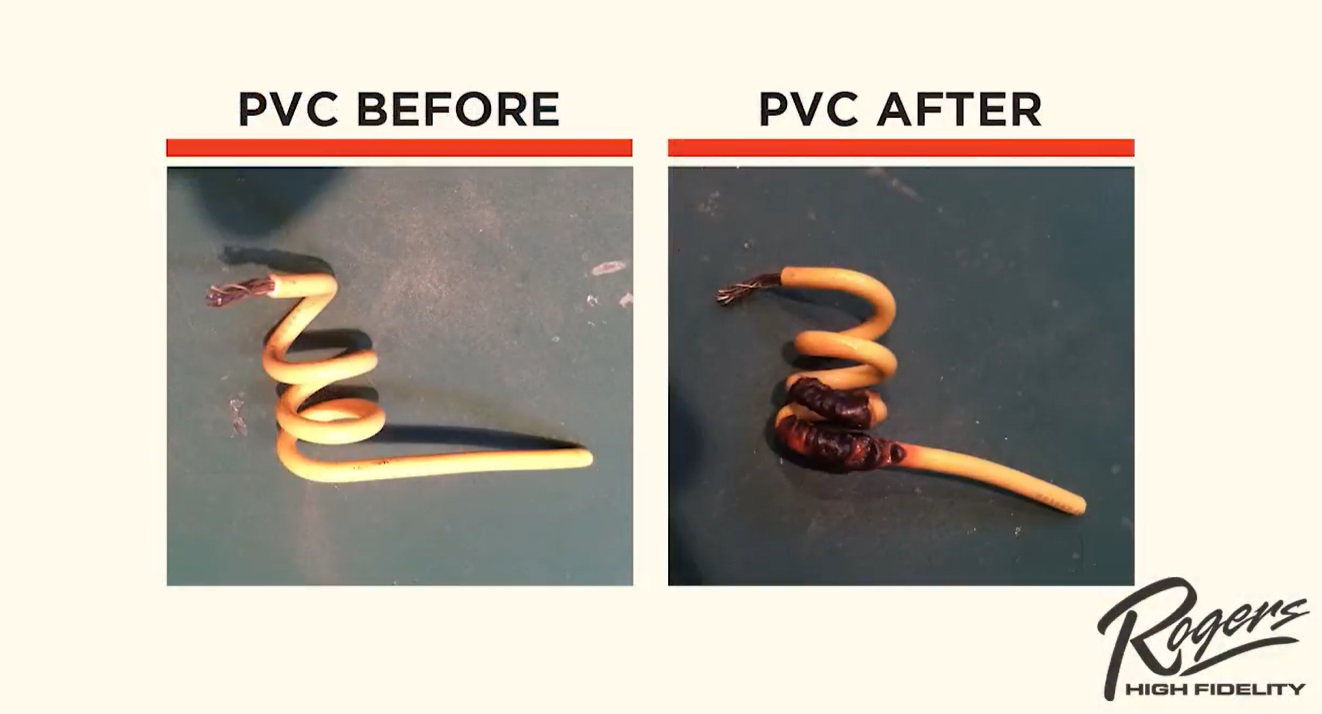

- Limited Temperature Range: PVC degrades at higher temperatures, limiting its use in high-temperature applications.

- Chemical Vulnerability: Susceptible to certain organic solvents and may not be suitable for chemically aggressive environments.

3.3 Advantages of PTFE Lead Wire

- High-Temperature Resistance: Suitable for extreme environments where other materials would fail.

- Chemical Resistance: Nearly impervious to chemical attack, suitable for the harshest environments.

- Excellent Electrical Properties: Low dielectric constant and high dielectric strength make it ideal for high-frequency and high-voltage applications.

3.4 Disadvantages of PTFE Lead Wire

- Cost: Significantly more expensive than PVC, which can be a limiting factor in its use.

- Rigidity: PTFE is less flexible, which can make installation more challenging, especially in tight spaces.

4. Cutting and Stripping PVC and PTFE Lead Wires with a Wire Processing Machine

The process of cutting and stripping lead wires varies depending on the insulation material. Wire processing machines are commonly used in manufacturing to automate these processes, ensuring precision and efficiency.

4.1 General Considerations

Before beginning the cutting and stripping process, consider the following:

- Wire Specifications: Ensure that the machine is set to handle the specific diameter and insulation type of the wire.

- Blade Type: Different blades may be required for PVC and PTFE due to their differing material properties.

- Speed Settings: The speed at which the wire is fed through the machine may need adjustment based on the material’s flexibility and thickness.

4.2 Cutting and Stripping PVC Lead Wire

Steps:

- Machine Setup: Set the machine to the correct wire gauge and insulation thickness. PVC is generally easier to cut and strip due to its softness.

- Feeding the Wire: Feed the PVC wire into the machine. Ensure it is straight and free of kinks to avoid jamming the machine.

- Cutting: The machine will use rotary blades or guillotine-style cutters to sever the wire to the desired length. PVC’s flexibility allows for smooth cuts without much resistance.

- Stripping: The machine then strips the insulation off the wire ends. Since PVC is relatively soft, standard stripping blades can easily remove the insulation without damaging the conductor.

- Quality Check: Inspect the stripped wire for any nicks or damage to the conductor, which could affect performance.

Considerations:

- PVC tends to deform under high pressure, so the stripping force should be carefully adjusted to avoid damaging the conductor.

4.3 Cutting and Stripping PTFE Lead Wire

Steps:

- Machine Setup: Due to PTFE’s hardness, set the machine to a lower feed rate and ensure that it’s equipped with sharp, durable blades designed for harder materials.

- Feeding the Wire: Feed the PTFE wire carefully into the machine. The wire should be handled with care to prevent damage to the insulation.

- Cutting: The machine uses a more robust cutting mechanism to sever PTFE wires. Due to PTFE’s resistance to cutting, the process may require more force and precision.

- Stripping: Stripping PTFE insulation requires precise blade alignment and sharpness. The machine will carefully score the insulation before stripping it off to avoid nicking the conductor.

- Quality Check: After stripping, inspect the wire for any damage to the insulation or conductor. PTFE’s hardness means any imperfections could lead to performance issues.

Considerations:

- PTFE is more prone to cracking if handled improperly during the stripping process, so ensure the machine settings are fine-tuned for this material.

5. Conclusion

Choosing between PVC and PTFE lead wires depends on the specific requirements of the application. PVC is a cost-effective, flexible, and widely available option for general-purpose wiring, while PTFE offers superior performance in high-temperature, chemically aggressive, and high-frequency environments.

When cutting and stripping these wires with a wire processing machine, the material properties significantly influence the process. PVC, being softer and more flexible, is easier to work with, while PTFE requires more precision and care due to its rigidity and high resistance to cutting.

Understanding these differences is crucial for selecting the right wire for your project and ensuring efficient and damage-free processing with the appropriate equipment.

Buy PVC Hook up wire here >

Buy PTFE (Teflon coated) Lead wire here >

Buy Cut lead wires here >