Aug 25, 2024

The History of Romex Cable and the Evolution of Color Codes According to the NEC

Introduction

Romex cable, a staple of modern residential wiring, has become synonymous with non-metallic sheathed cable (NM cable) in the electrical industry. Its simplicity, cost-effectiveness, and ease of installation have made it a go-to option for electricians and do-it-yourself homeowners alike. Over the years, Romex cable has undergone numerous transformations, especially with regard to safety and usability standards dictated by the National Electrical Code (NEC). One of the most prominent developments is the standardized color-coding of Romex cable, which allows electricians to quickly identify the wire gauge and its corresponding current-carrying capacity.

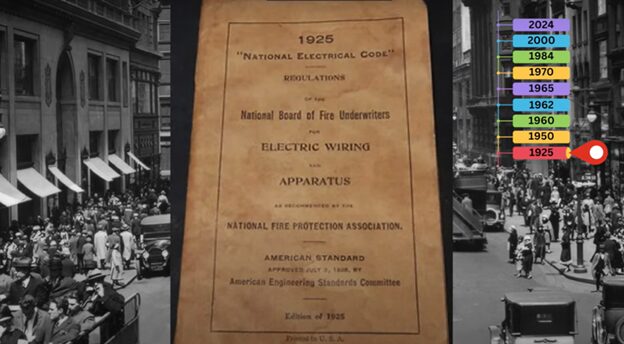

0:20 – Birth in 1925

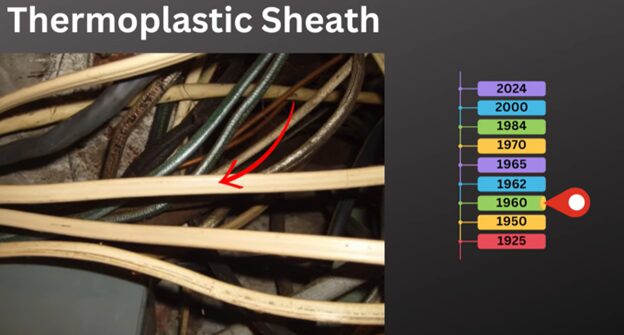

1:09 – Thermoplastic sheath

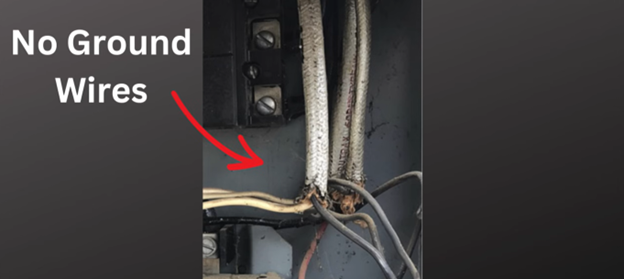

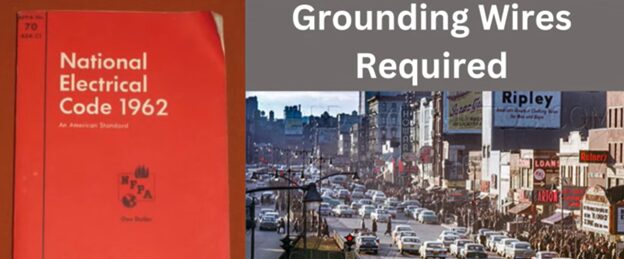

1:30 – Ground wire addition

1:59 – Temperature changes

2:35 – Color jacket changes

4:00 – New color codes for 3 conductor in 2024

In this article, we’ll explore the history of Romex cable, tracing its evolution from its invention to its modern form. We’ll also delve into the NEC’s implementation of color codes for different American Wire Gauge (AWG) sizes, particularly 14, 12, and 10 AWG cables, and examine the significance of these changes.

The Birth of Romex Cable: A Revolution in Residential Wiring

Origins of Non-Metallic Sheathed Cable

Before Romex and other forms of NM cable came into existence, residential wiring largely consisted of knob-and-tube systems or cloth-wrapped wires running inside metal conduits. These older methods, while functional, were time-consuming to install and often posed significant fire hazards due to insulation degradation over time.

The evolution of residential wiring took a significant leap forward in the 1920s when the concept of non-metallic sheathed cable was introduced. This new type of cable featured a rubber or plastic outer jacket encasing multiple insulated conductors, which provided a simpler, safer alternative to traditional wiring methods. One of the most popular early versions of NM cable was Romex, a product created by Rome Wire Company in the 1920s.

Early Romex: A Growing Standard

The Rome Wire Company developed Romex to be a flexible, easy-to-install alternative to other wiring methods. By encasing individual conductors in a non-metallic jacket, Romex protected wires from physical damage while making installation faster and safer. This quickly earned Romex a place in residential wiring systems.

Though Romex began its life as an unbranded innovation, it soon became the preferred choice for home electrical installations. By the 1940s and 1950s, Romex had become a household name, and the use of NM cable was widely accepted for branch circuit wiring in homes across the United States.

The National Electrical Code and Safety Standards for NM Cable

The NEC’s Role in Wiring Safety

The National Electrical Code (NEC) plays a critical role in regulating electrical wiring practices in the U.S. It is published by the National Fire Protection Association (NFPA) and is updated every three years to address new technologies, materials, and safety concerns. One of the NEC’s primary functions is to set standards for the installation of electrical wiring, ensuring that systems are safe, efficient, and reliable.

Romex and other NM cables have long been subject to the standards and guidelines set forth by the NEC. The code addresses various aspects of wiring, including the types of materials used, the method of installation, and the wire’s current-carrying capacity (ampacity). Over the years, these standards have evolved to include color codes for identifying the size and application of conductors.

The Push for Standardized Color Codes

Before the 1990s, NM cables often lacked standardized color coding, which created potential confusion and increased the risk of electrical errors. Electricians would have to inspect the wire’s markings to determine its gauge and ampacity, which was time-consuming and error-prone, especially in dimly lit environments.

As a solution, the NEC began implementing mandatory color-coding systems for NM cable to help electricians quickly and accurately identify wire sizes. This standardization has been an essential development for the safety and efficiency of electrical installations. Below, we’ll delve into the specific color coding for 14, 12, and 10 AWG Romex cables and the impact of these changes on the industry.

Color Coding for Romex Cable: A Detailed Look

The Importance of Wire Gauge

The American Wire Gauge (AWG) system is a standardized system that measures the diameter of electrical conductors. The smaller the AWG number, the larger the conductor’s diameter and the higher its ampacity—the amount of current the wire can safely carry. Understanding wire gauge is crucial for ensuring that circuits are properly designed and capable of carrying the necessary electrical loads.

14, 12, and 10 AWG Romex cables are the most commonly used sizes in residential wiring, each serving different applications based on their ampacity. These sizes are now color-coded to help identify them at a glance.

Color Codes for 14, 12, and 10 AWG Romex Cable

14 AWG Romex Cable

14 AWG Romex cable is typically used for general lighting circuits and outlets in homes. It is rated for 15 amps, making it suitable for lower-power applications.

Color Code: White

- In accordance with NEC standards, 14 AWG Romex cable is encased in a white outer sheath. The adoption of this color code has made it easier to quickly identify this smaller-gauge wire and ensure it is only used in 15-amp circuits. The use of white sheathing for 14 AWG cable became widespread in the early 2000s as the NEC moved toward uniform color coding across all NM cables.

12 AWG Romex Cable

12 AWG Romex cable is one of the most common wire sizes used in residential electrical systems. Rated for 20 amps, it is used for power outlets, kitchen appliances, and some lighting fixtures. Due to its higher ampacity, it can safely handle more power-intensive devices.

Color Code: Yellow

- The NEC mandates that 12 AWG Romex cable be color-coded with a yellow outer sheath. The yellow sheathing makes it easy to differentiate from 14 AWG (white) cable, particularly in junction boxes and breaker panels where multiple wires converge. Yellow sheathing for 12 AWG Romex became a requirement around 2001, further reducing confusion and installation errors.

10 AWG Romex Cable

10 AWG Romex cable is used for heavier-duty circuits that require more power, such as those for large appliances like water heaters, air conditioners, and dryers. This wire size is rated for 30 amps.

Color Code: Orange

- In accordance with NEC guidelines, 10 AWG Romex cable is encased in an orange sheath. This color distinction is particularly useful when dealing with higher amperage circuits, as it signals to electricians that the wire is not suitable for standard 15 or 20-amp circuits. The orange sheath for 10 AWG Romex was standardized around the same time as the color coding for 12 and 14 AWG cables, reinforcing the push toward safer and more organized wiring installations.

The Impact of Color Coding on Electrical Safety and Efficiency

The NEC’s adoption of standardized color coding for Romex cable has had a significant positive impact on the electrical industry. Here are a few key benefits:

- Improved Safety: The color codes help electricians avoid the dangerous mistake of connecting the wrong gauge wire to a circuit breaker or device. Using the correct wire gauge is critical to preventing overheating and electrical fires.

- Increased Efficiency: Color-coded cables allow electricians to quickly identify wire sizes, which speeds up the installation process and reduces the chance of errors. This is especially important in complex installations where many different circuits are present.

- Simplified Inspections: For electrical inspectors, color coding makes it easier to verify that the correct wire sizes have been used for specific circuits. This is particularly valuable during code inspections for new construction or renovations.

- Enhanced Organization: In residential and commercial electrical installations, proper color coding promotes better organization in breaker panels and junction boxes, reducing clutter and making future troubleshooting simpler.

Beyond Color Coding: Other Developments in Romex Cable

In addition to the introduction of color coding, Romex cable has continued to evolve in response to changing industry standards and safety requirements. Some of these developments include:

- Enhanced Insulation Materials: Over time, the insulation materials used in Romex cable have improved, offering greater resistance to heat, moisture, and physical damage. Modern Romex cables are typically made with thermoplastic insulation, which is more durable and flame-resistant than the rubber and cloth insulations used in earlier versions.

- Grounding Conductors: Today, most Romex cables include a bare copper grounding wire, which was not always a standard feature in older cables. Grounding conductors provide an additional layer of safety by ensuring that any stray electrical current is directed safely to the ground.

- Weather-Resistant Versions: For outdoor and damp locations, NM-B cable (indoor use only) has been complemented by UF (Underground Feeder) cable, which is designed to withstand exposure to moisture and the elements.

New 3 Conductor Color Code in 2024

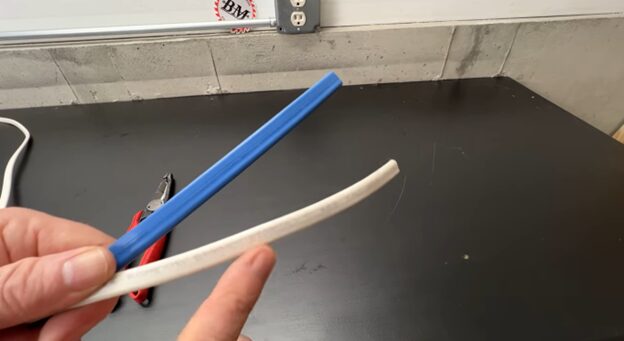

Romex has implemented a new color for all 3 conductor cables to distinguish between 2 and 3 conductor cables from a visual perspective. For example, Romex 14/2 remains white but 14/3 now comes in a blue jacket.

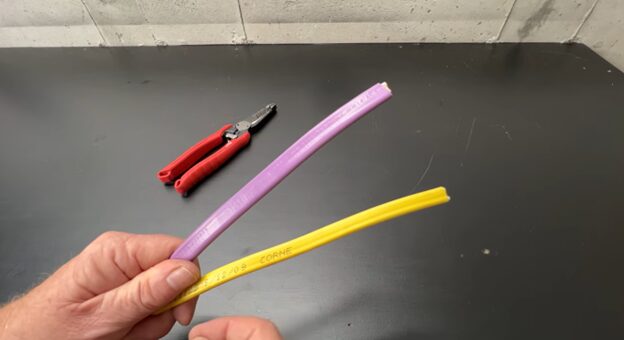

Romex 12/2 remains yellow but 12/3 is now purple.

Finally, Romex 10/2 remains orange but 10/3 is now pink.

Conclusion

Romex cable has come a long way since its introduction in the 1920s. Its history is deeply intertwined with the development of modern residential electrical systems, and it remains a critical component of safe and efficient home wiring. The NEC’s introduction of color coding for different wire gauges, specifically 14, 12, and 10 AWG, has further enhanced the safety, efficiency, and reliability of electrical installations.

By standardizing these color codes, the NEC has helped to reduce confusion, prevent mistakes, and ensure that wiring systems meet the highest safety standards. Electricians and homeowners alike can now work more confidently, knowing that the cables they use are easy to identify and suited to their intended applications.

As we look to the future, it’s clear that Romex cable and the NEC’s safety guidelines will continue to play a vital role in the evolution of residential and commercial wiring systems, ensuring that they remain safe, reliable, and capable of meeting the demands of modern living.