May 5, 2021

What Is DLO Cable and What Is It Used For?

DLO stands for Diesel Locomotive because it is most commonly used for diesel locomotive applications. However, as a very powerful single conductor cable, it can be used in multiple single-phase applications such as oil and gas drilling rigs, cranes, shipyards, motor leads and mining applications. DLO cables are rated for 2000 volts and are used in industrial applications more often than in residential areas.

About DLO

Locomotive cables have two layers of insulation to protect them in severe conditions and support their Underwriters Laboratories (UL)-approved 2,000-volt rating. This insulation is made of ethylene propylene rubber (EPR) and chlorinated polyethylene (CPE) for a flexible and rugged design. Inside the insulation, you’ll find 24-gauge copper conductors with a tin coating.

The rubber insulation layers are quite flexible, so DLO cable can still be convenient and portable. This cable can also support temperatures up to 90 degrees Celsius and is commonly used for locomotive and motor leads.

DLO cable is resistant to:

- Oils.

- Acids.

- Alkalies.

- Heat.

- Flame.

- Sunlight.

It also complies with the Restriction of Hazardous Substances (RoHS) and has approvals from UL, the CSA Group and the Mine Safety and Health Association (MSHA).

WesBell Electronics offers all different sizes of DLO cables, including AWG from 8 to 4/0. We can supply you with MCM sizes as well, from 262 to 777 MCM.

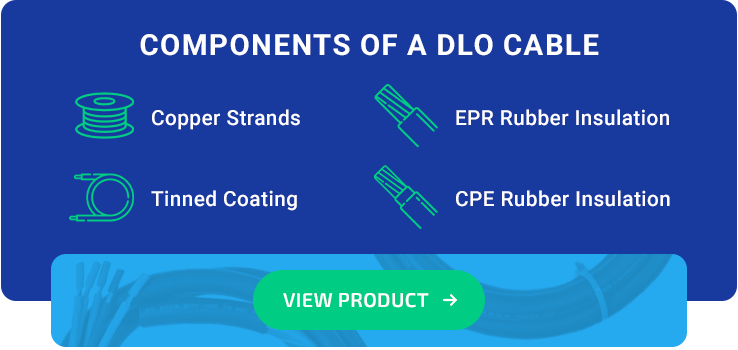

What Is DLO Cable Made Of?

1. Copper Strands

DLO stands for Diesel Locomotive cable and the thin copper strands help with the flexibility of the cable. DLO cable uses 24 AWG strands in all sizes from 14 AWG to 1111 MCM. Each AWG increase uses more strands until it reaches the necessary diameter of the gauge in question. DLO cable is much more flexible than typical electrical wire or building wire but slightly less flexible than welding cable and stage lighting cable.

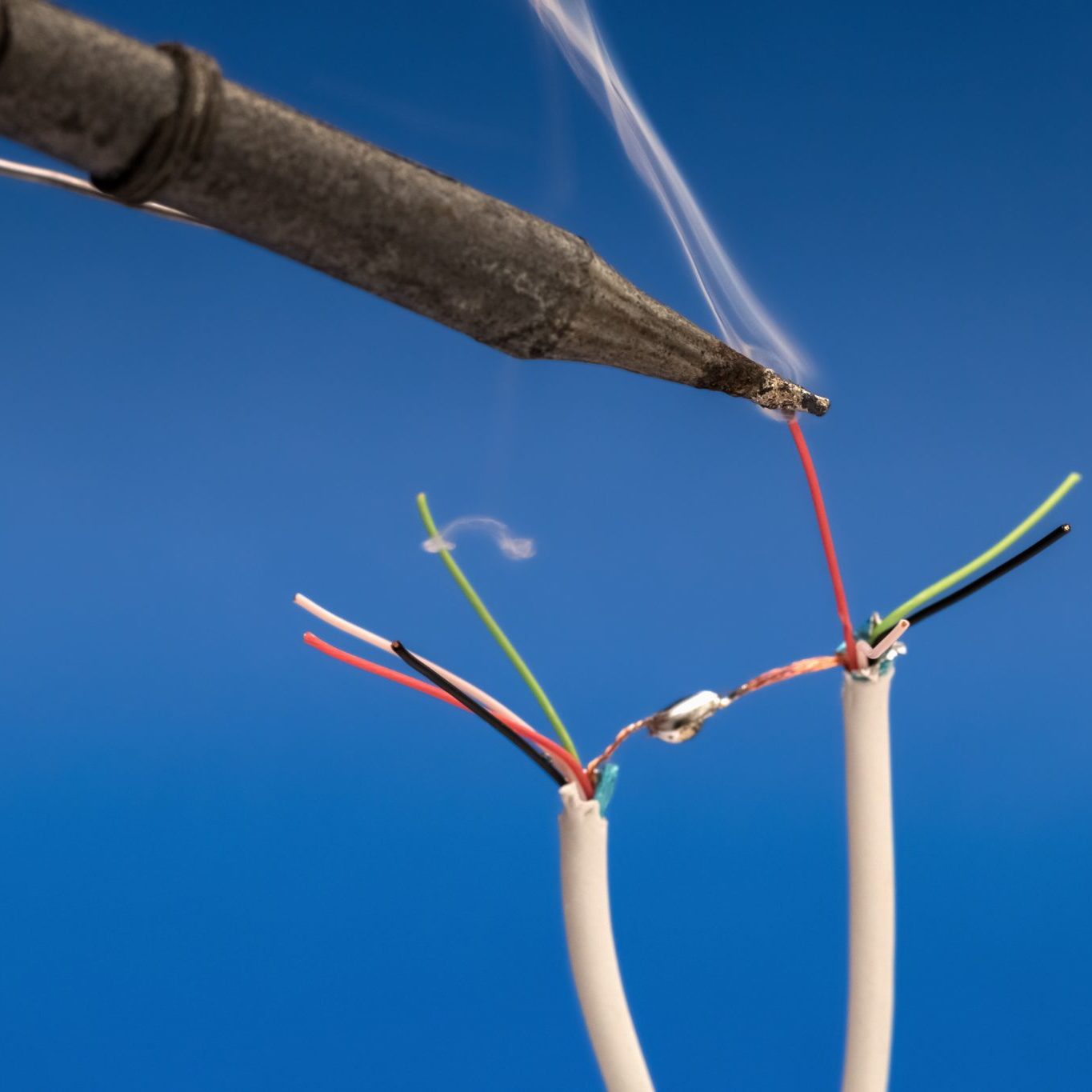

2. Tinned Coating

The most portable cord has bare copper strands which make DLO cable unique in this area. There is a tinned coating over each strand in diesel locomotive cable to help adhere to the adhesive when connecting lugs. The adhesive is placed on the copper strands before applying the lug which helps the connection from the lug to the adhesive to the tinned copper strands.

3. EPR Rubber Insulation

The EPR rubber insulation is the first layer of insulation used on DLO cable. Since it’s used outdoors to connect power to diesel locomotives and telecom supply it needs to have plenty of protection. The jacket needs to be strong and durable because it takes quite a bit of daily abuse in its application.

4. CPE Rubber Insulation

Remember, “portable” power cables are stepped on, run over, dragged along the ground, and constantly caught in tight areas that could puncture the insulation and expose the copper strands. Therefore, the second layer of CPE rubber insulation is applied to DLO cables for a double layer of protection. The voltage rating is also 2000 volts which are higher than one-layer-portable-cables at 600 volts.

How DLO Wire Stacks Up

There are many similar cables on the market, but most don’t come close to the strength and ruggedness of DLO cable. Welding cables, entertainment cables and multiconductor cables are typically inferior to DLO cable but can be more cost-effective if the durability and performance of DLO cable aren’t needed. For instance, all the cables listed below are rated for 600 volts and none can match the dual-insulation layers that protect DLO cable’s copper conductors from threats as large as dump trucks.

WesBell Electronics stocks many different types of power cable. If DLO isn’t what you need, we have other options:

- Welding cable: If DLO cable provides more toughness than you need for your application, welding cable is a good choice. It’s similar to DLO cable but has a single layer of rubber insulation and is rated for 600 volts. This kind of cable is better suited for garages and shops with low-voltage equipment.

- Service, oil-resistant and weather/water-resistant (SOOW) cable: SOOW cable is a multiconductor power cable often used for smaller devices and as a locomotive cable thanks to its exceptional flexibility and versatility.

- Entertainment cable: Stage lighting cable is another 600-volt cable that offers heat resistance up to 105 degrees Celsius.

If you’re not sure what kind of cable you need, the knowledgeable representatives at WesBell Electronics can help you figure out which one is right for the job.

Flexible and Protective

Rather than buying DLO cable for its high voltage rating, you might want to buy it for its flexibility or dually protective jacket. Diesel locomotive cables are manufactured with a layer of EPR insulation and a second layer of CPE insulation for industrial-type protection. Imagine using a cable in an industrial setting compared to a residential setting to understand why the added protection is given to DLO cables.

Approvals

Unlike residential portable power cables, industrial power cables carry UL, CSA and MSHA approvals. These approvals are stamped on the jacket to prove that Underwriters Laboratories, Canadian Standard Association and Mine Safety and Health Administration have tested and approved the ratings given to DLO cable. Without those third-party approvals, it will be difficult for industrial applications to pass inspection. Those needing cables without UL, CSA and MSHA approvals would typically be homeowners and small machine shops that don’t need to pass inspection.

Is There a Cheaper Alternative to DLO?

That depends on your requirements. If your application can get by with a 600-volt cable, less protection and a lower voltage rating then the answer is yes, welding cable. Welding cable does not carry the approvals and it’s only rated for 600 volts with a single layer of rubber insulation. It’s much cheaper and offered in similar AWG (American Wire Gauge) sizes as DLO. Welding cable is also offered in black, red and orange, whereas DLO cable only comes with black insulation.

Learning about the power cable you’re looking to buy is a very good idea because you could be buying more or less than you actually need. Speaking with your supplier will help you understand each attribute the cable has to offer and which of them your application needs. Cutting out one attribute, such as switching from 2000 volts to 600 volts, will save you a lot of money.

Diesel Locomotive Cable from WesBell Electronics

Browse our DLO cable products and reach out to us with questions or custom specs.