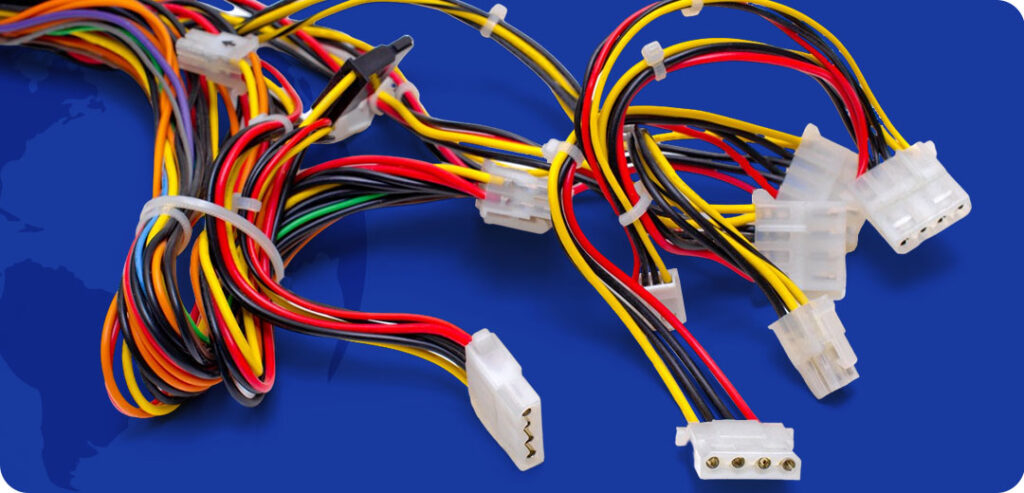

Wire Harness Assembly

WesBell’s wire harness assembly services are tailored to meet and exceed ISO standards and we have strong relationships with our clients that stem from our commitment to produce quality wire products and services. Wire harness services are completed for companies, big and small, once their research and development team (engineers) design the harness to fit inside of an electronic device. Most often the measurements and tolerances are tight so that it’s not too short and not too long. Harnesses that are longer than necessary waste room inside the device and cost more money to produce, so WesBell has strict processes to meet the tolerances specified by the customer before shipping the product.

Contact Us for Wire Harness Assembly

WesBell’s Wire Harness Customer Service Team

WesBell conducts business with customers throughout the United States. We not only support local customers, but we also visit our customers in-person across the country. Discussing orders with polite and knowledgeable people is necessary to build a long-lasting relationship. Our staff is trained verbally and physically with our wire harness assembly manufacturer processes in order to speak to our customers clearly and efficiently. You won’t catch us trying to “sell” our products. Instead, you’ll find that we keep you on the phone longer to ask you about the risks of building each part, the tolerances you expect, the first article process and much more. We aren’t afraid to discuss the risk of building something with you, and how we can mitigate that risk by having you approve the first article or by purchasing a certain tool to improve consistency. Risk management is a major part of every business and a major part of every department so be prepared to discuss it with us when you request wire harness services.

First Article Approval for Risk Management and Customer Satisfaction

It’s important to WesBell to get a first article, or sample, approved by the customer when we’re producing a job for the first time. We’ll review the specification sheet created by the customer and assemble the harness as we interpret it. We build one for the customer and one for ourselves to review later if it’s approved. We keep a library of each part so that we can use it as a visual while producing future orders. We take it very seriously and want the customer to do so as well. Without approval, we run the risk of wasted product and labor, and waste build-up creates higher costs which never turn into cost savings for our customers. We manage, assess and mitigate risk opportunities before we run into problems instead of fixing problems after they appear. We strongly believe it helps us give more competitive pricing to customers in the long run.

WesBell Wire Harness Assembly Manufacturing Process

Once our equipment cuts the wire, crimps the terminals and semi-strips the insulation, our assemblers will follow customer data sheets in order to construct the complete wire harness assembly. We use various materials such as plastic zip ties, heat shrink tubing, plastic housing, clamps, expandable sleeving and solder. We also have numerous tooling products such as hand tools, hydraulic tools, foot pedal-operated tools and various wire cutters. Our processes and procedures in place to manage risk associated with creating assembly jobs that require first article approvals, quality checks throughout the assembly process and final inspection signature from management before shipping.

Quality Management throughout the Assembly Process

Our assembly process has a Quality Inspection Report that needs to be signed by each assembler after each process is complete. The assembler needs to sign the sheet and have a manager sign the sheet after both of them have measured and approved the accurate dimensions. It’s like using spell check, rereading, and then having a peer proofread in order to minimize errors. Lastly, there is a final check completed by the manager to assure that the entire wire harness meets the exact needs of the customer.

Long Term Quality and Consistency

Our quality process is strong and it’s also continuously improving year after year. “If it ain’t broke, don’t fix it” is NOT a motto we follow here. We look to improve every process and procedure regularly whether it’s part of our production team, quality team, management team or customer service team. We assure ourselves and commit to meeting the concern of long-term quality and consistency by completing the first article approval by the customer, using the sample part as a visual, approving the revision level upon every new order, following our Quality Inspection Report and completing a final check of the parts before they ship.

Annual Cost Reductions for Customers

Many of our customers send annual letters to open the discussion of reducing costs for the upcoming year. As we grow our company, we get new customers that require us to purchase new equipment and tooling, and sometimes those investments can be used on more than that single customer. For example, we might use a hand crimping tool to create a harness for a customer and we have been charging them accordingly for the last year. Then we get a new customer that wants us to build a similar harness in a much higher volume, so we buy a machine to lower the costs of producing it. Once we have the new machine we can reevaluate the current wire harness assembly manufacturer processes to see if we can lower the total labor cost. Then we can pass part of those savings onto the customer and everyone wins. We consistently use this process to lower costs for our customers on an annual basis.

Speed of Delivery or Just-in-Time Delivery

Typically, long-term customers will call us frantically and ask, “How soon can we get this?” It happens in every industry, so we’re all familiar with it. The same customers, and more, will place orders with specific delivery dates that are required because they have production plans at their facility that depend on those materials. Our customer service team is trained to figure out how customers want to receive their products and we create our production schedule with those thoughts in place. We have temp agencies on call ready to send us employees that have production skills with only one-day notice. That turns the question of, “How soon can we get this?” into “How soon do you want it?”

The Just-in-Time delivery method usually also has a buffer quantity of wire harnesses sitting on the shelf, and it can be a lifesaver. When a customer has concerns about delivery we often ask them if they want us to produce a buffer quantity of assemblies that can be shipped the day they call. Rushing to produce products creates a risk of human error that can be tough to control which is alleviated when we regularly produce the buffer quantity, ship it right away, and regularly produce the balance. We will continue to develop new ways to improve deliveries without adding any risk to the process of speed.